Catalytic pre-oxidation treatment and reuse technology of refractory biochemical and high-salt mine beneficiation wastewater

A technology for pre-oxidation treatment and wastewater treatment, applied in mining wastewater treatment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of filler agglomeration, high cost, passivation, etc. The effect of high sedimentation and breakthrough of technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

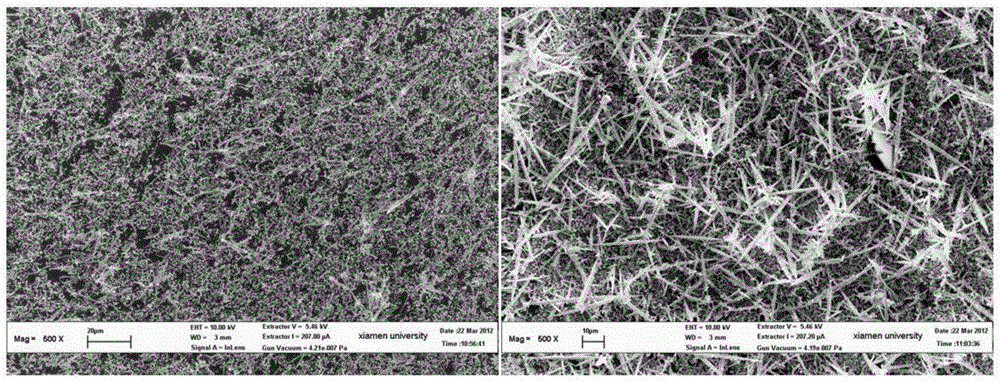

Image

Examples

Embodiment 1

[0032] A mineral processing plant in the Yunnan-Guizhou Plateau, due to the implementation of the zero discharge system, all kinds of production and domestic sewage enter the tailings pond. The average COD concentration of the tailings pond fluctuates between 1000 and 1500 mg / L. The wastewater BOD / COD is lower than 0.3, which is difficult Biochemical waste water with high salt content has high hardness and salinity, so it cannot be directly discharged and recycled.

[0033] Preparation of ozone catalyst: use a vacuum pump to control the pressure of the reaction chamber to be less than 100Pa; the cathode uses a graphite disc with a diameter of 50 mm, and the anode uses a graphite rod with a diameter of 10 mm and a length of 250 mm. One end of the graphite rod is drilled with a diameter of 2 mm and a depth of It is a hollow hole of 200mm, which is filled with a uniform mixture of nickel powder and manganese powder, and the mass ratio of nickel powder and manganese powder in the u...

Embodiment 2

[0042] The COD concentration of wastewater from a certain mine is 1800-2500mg / L, which is biochemically difficult and high-salinity wastewater, which cannot be directly discharged and recycled.

[0043] Preparation of ozone catalyst: use a vacuum pump to control the pressure of the reaction chamber to be less than 100Pa; the cathode adopts a graphite disc with a diameter of 60mm, and the anode adopts a graphite rod with a diameter of 8mm and a length of 270mm. One end of the graphite rod is drilled with a diameter of 1.5mm. A hollow hole with a depth of 220mm is filled with a uniform mixture of nickel powder and manganese powder, and the mass ratio of nickel powder and manganese powder in the uniform mixture is 2.5:3.5; open the cooling water in the reaction chamber, control The distance between the anode and the cathode is 1mm, and the discharge current intensity is controlled to be 75-80A; when the anode graphite rod consumes 220mm, the reaction is stopped, and after cooling ...

Embodiment 3

[0049] In a concentrator, the COD concentration of wastewater is 800-1200mg / L, and the water has high hardness and salinity, so it cannot be directly discharged and recycled.

[0050] The preparation of ozone catalyst: adopt vacuum pump to control reaction cavity pressure to be less than 100Pa; Cathode adopts the graphite disk that diameter is 40mm, and anode adopts the graphite rod that diameter is 12mm, and length is 230mm, and one end of this graphite rod is drilled with diameter is 2.5mm, A hollow hole with a depth of 180 mm is filled with a homogeneous mixture of nickel oxide and manganese oxide, and the mass ratio of nickel element to manganese element in the homogeneous mixture is 1.5:2.5; open the reaction chamber cooling water, control The distance between the anode and the cathode is 3mm, and the discharge current intensity is controlled to be 85-90A; when the anode graphite rod consumes 180mm, stop the reaction, after cooling to room temperature, turn off the cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com