Flocculating agent as well as raw material composition, preparation method and application thereof

A raw material composition and flocculant technology, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water treatment parameter control, etc., can solve the problems of high toxicity of chemical flocculants, difficulty in post-treatment, waste liquid utilization rate, etc. Low-cost problems, to achieve the effect of improving settleability, simple and easy preparation steps, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

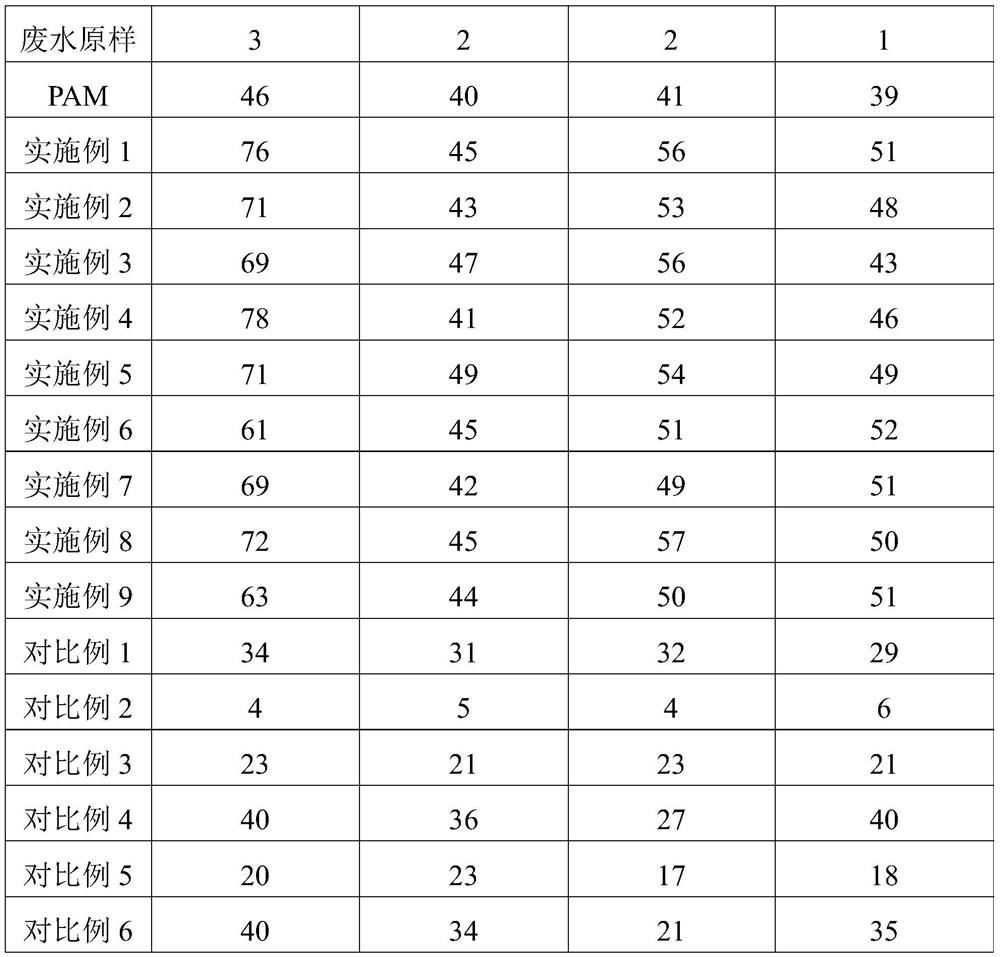

[0058] In the following examples and comparative examples; the preparation method of pulping waste liquid comprises the following steps: taking poplar as raw material, pulping through the PRC-APMP pulping method, removing the remaining material after the pulp is pulping waste liquid, pulping waste The solids content of the liquid was 57%.

[0059] The pulping waste liquor includes the following components in parts by weight: 50 parts of cellulose, 15 parts of lignin, 0.15 parts of xylose and 32 parts of sodium acetate.

[0060] The polyacrylamide in the following examples is a cationic polyacrylamide with a number average molecular weight of 9×10 6 about.

Embodiment 1

[0062] (1) Add 50 g of pulping waste liquid and 325 g of deionized water into a 500 mL beaker, stir for 5 min, pass through an 80-mesh sieve, and collect the filtrate;

[0063] Add the above-mentioned filtrate into a four-necked flask with a condenser tube and a stirring rotor. At room temperature, add 7.5 g of polyacrylamide into the four-necked flask in three times, and mix for 10 minutes to obtain pulping waste liquid and polyacrylamide. mixture;

[0064] At a temperature of 50°C, add 10 g of 10% by mass ammonium persulfate aqueous solution dropwise to the mixture of pulping waste liquor and polyacrylamide for 10 minutes; after the dropwise addition, continue to mix and react for 30 minutes, Material A is obtained;

[0065] (2) Under the condition that the temperature is 50° C., add 15 g of potassium persulfate aqueous solution with a mass fraction of 10% dropwise to the material A prepared in step (1), and the dropping time is 15 minutes; continue the mixing reaction afte...

Embodiment 2

[0068] (1) Add 50 g of pulping waste liquid and 325 g of deionized water into a 500 mL beaker, stir for 5 min, pass through an 80-mesh sieve, and collect the filtrate;

[0069] Add the above-mentioned filtrate into a four-necked flask with a condenser tube and a stirring rotor. At room temperature, add 5 g of polyacrylamide into the four-necked flask in six times and mix for 10 minutes to obtain a mixture of pulping waste liquid and polyacrylamide. mixture;

[0070] At a temperature of 50°C, add 10 g of 10% by mass ammonium persulfate aqueous solution dropwise to the mixture of pulping waste liquor and polyacrylamide for 10 minutes; after the dropwise addition, continue to mix and react for 30 minutes, Material A is obtained;

[0071] (2) Under the condition that the temperature is 50° C., add 15 g of potassium persulfate aqueous solution with a mass fraction of 10% dropwise to the material A prepared in step (1), and the dropping time is 15 minutes; continue the mixing react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com