Granular 13x molecular sieve/attapulgite loaded nano-iron-nickel material and preparation method thereof

A technology of attapulgite and molecular sieve, which is applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve the problems of poor selectivity of activated carbon, high price of activated carbon, high production cost of materials, etc. Settability, effect of good reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

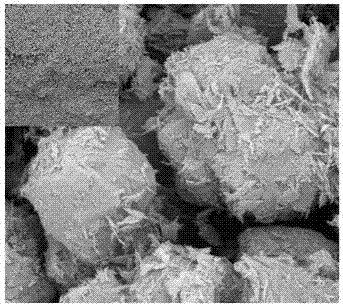

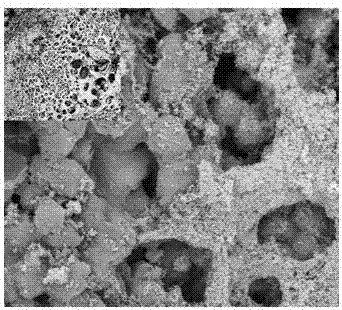

[0028] A granular 13X molecular sieve / attapulgite loaded nano-iron-nickel material and a preparation method thereof. The preparation steps of this embodiment are:

[0029] Step 1, according to the mass ratio of 13X molecular sieve powder: attapulgite powder is 1: (0.25 ~ 1), mix 13X molecular sieve and attapulgite powder evenly, make 13X molecular sieve / attapulgite powder; then press 13X molecular sieve / attapulgite powder Attapulgite powder: the mass ratio of distilled water is 1: (1.4~1.5), add distilled water to 13X molecular sieve / attapulgite powder, stir evenly, make 13X molecular sieve / attapulgite mud; then mix 13X molecular sieve / attapulgite mud The soil mud is baked at a temperature of 90-95°C for 10-12 hours to obtain a 13X molecular sieve / attapulgite mud block.

[0030] Step 2. Break the 13X molecular sieve / attapulgite mud block obtained in step 1 and grind it to particles with a particle size of 0.45~0.9mm; then place the particles in a muffle furnace at a temperatu...

Embodiment 2

[0038] A granular 13X molecular sieve / attapulgite loaded nano-iron-nickel material and a preparation method thereof. The preparation steps of this embodiment are:

[0039]Step 1. According to the mass ratio of 13X molecular sieve powder: attapulgite powder is 1: (1~3), mix 13X molecular sieve and attapulgite powder evenly to obtain 13X molecular sieve / attapulgite powder; then press 13X molecular sieve / attapulgite powder Attapulgite powder: the mass ratio of distilled water is 1: (1.5~1.6), add distilled water to 13X molecular sieve / attapulgite powder, stir evenly, make 13X molecular sieve / attapulgite mud; then mix 13X molecular sieve / attapulgite mud The soil mud is baked at a temperature of 95-100°C for 9-10 hours to obtain a 13X molecular sieve / attapulgite mud block.

[0040] Step 2. Break the 13X molecular sieve / attapulgite mud block obtained in step 1 and grind it to particles with a particle size of 0.45~0.9mm; then place the particles in a muffle furnace at a temperature...

Embodiment 3

[0048] A granular 13X molecular sieve / attapulgite loaded nano-iron-nickel material and a preparation method thereof. The preparation steps of this embodiment are:

[0049] Step 1. According to the mass ratio of 13X molecular sieve powder: attapulgite powder is 1: (3~6, mix 13X molecular sieve and attapulgite powder evenly to obtain 13X molecular sieve / attapulgite powder; then press 13X molecular sieve / attapulgite powder Attapulgite powder: the mass ratio of distilled water is 1: (1.6~1.8), add distilled water to 13X molecular sieve / attapulgite powder, and stir evenly to obtain 13X molecular sieve / attapulgite mud; then mix 13X molecular sieve / attapulgite mud with The mud is dried at a temperature of 100-105°C for 8-9 hours to obtain 13X molecular sieve / attapulgite mud blocks.

[0050] Step 2. Break the 13X molecular sieve / attapulgite mud block obtained in step 1 and grind it to particles with a particle size of 0.45~0.9mm; then place the particles in a muffle furnace at a temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com