Preparation method of MOF-derived layered double hydroxide electrocatalyst with hollow structure

A hydroxide electric and layered double technology, applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as instability of precious metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

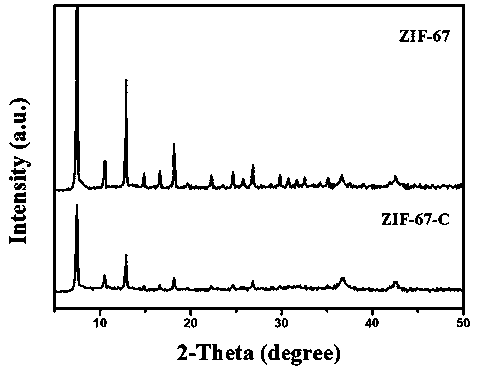

[0019] Step S1: Dissolve 2.91g of cobalt nitrate and 3.2g of dimethylimidazole in 200mL of methanol respectively to obtain solution A and solution B, add solution B to solution A and mix well, age the mixed solution at room temperature for 24 hours, centrifuge The precipitate was collected, washed with water and ethanol, and dried at 60°C to obtain ZIF-67, and then ZIF-67 was annealed at 400°C for 2 hours at a heating rate of 1°C / min under a nitrogen atmosphere to obtain ZIF-67-C;

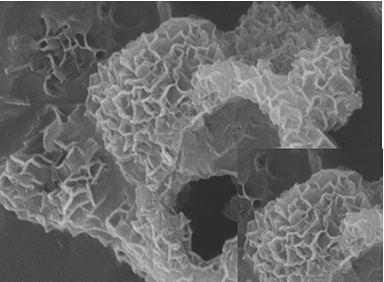

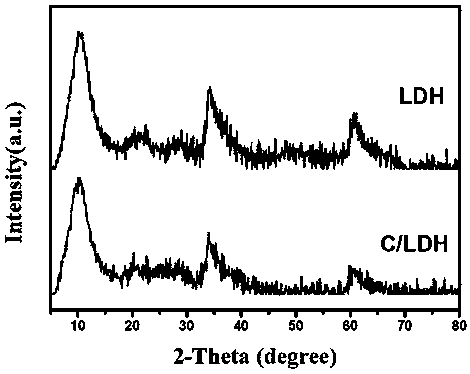

[0020] Step S2: Disperse 12 mg of ZIF-67-C and 24 mg of nickel nitrate hexahydrate in 30 mL of ethanol and conduct a hydrothermal reaction at 120°C for 2 hours, collect the precipitate by centrifugation, wash with water and ethanol and dry at 60°C to obtain C / LDH;

[0021] Step S3: Put 50 mg of sodium hypophosphite and 10 mg of C / LDH in a tube furnace, heat up to 200 °C at a rate of 1 °C / min and anneal for 2 h to finally prepare a layered double hydrogen oxide with a hollow structure derived from MO...

Embodiment 2

[0023] Step S1: Dissolve 2.91g of cobalt nitrate and 3.2g of dimethylimidazole in 200mL of methanol respectively to obtain solution A and solution B, add solution B to solution A and mix well, age the mixed solution at room temperature for 24 hours, centrifuge The precipitate was collected, washed with water and ethanol, and dried at 60°C to obtain ZIF-67, and then ZIF-67 was annealed at 400°C for 2 hours at a heating rate of 1°C / min under a nitrogen atmosphere to obtain ZIF-67-C;

[0024] Step S2: Disperse 12 mg of ZIF-67-C and 24 mg of nickel nitrate hexahydrate in 30 mL of ethanol and conduct a hydrothermal reaction at 120°C for 2 hours, collect the precipitate by centrifugation, wash with water and ethanol and dry at 60°C to obtain C / LDH;

[0025] Step S3: Put 100mg sodium hypophosphite and 10mg C / LDH in a tube furnace, heat up to 200°C at a rate of 1°C / min and anneal for 2 hours to finally prepare a layered double hydroxide derived from MOF with a hollow structure electro...

Embodiment 3

[0027] Step S1: Dissolve 2.91g of cobalt nitrate and 3.2g of dimethylimidazole in 200mL of methanol respectively to obtain solution A and solution B, add solution B to solution A and mix well, age the mixed solution at room temperature for 24 hours, centrifuge The precipitate was collected, washed with water and ethanol, and dried at 60°C to obtain ZIF-67, and then ZIF-67 was annealed at 400°C for 2 hours at a heating rate of 1°C / min under a nitrogen atmosphere to obtain ZIF-67-C;

[0028] Step S2: Disperse 12 mg of ZIF-67-C and 24 mg of nickel nitrate hexahydrate in 30 mL of ethanol and conduct a hydrothermal reaction at 120°C for 2 hours, collect the precipitate by centrifugation, wash with water and ethanol and dry at 60°C to obtain C / LDH;

[0029] Step S3: Put 150mg sodium hypophosphite and 10mg C / LDH in a tube furnace, heat up to 200°C at a rate of 1°C / min and anneal for 2 hours to finally prepare a layered double hydroxide derived from MOF with a hollow structure electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com