Preparation method of phosphorus-doped graphite phase carbon nitride nano film

A graphite-phase carbon nitride and nano-film technology, applied in coatings and other directions, can solve the problems of poor water solubility of powder materials, complicated preparation process, and reduced catalytic performance, and achieve good shape, simple preparation process, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of phosphorus-doped graphite phase carbon nitride nano film comprises the following steps:

[0022] (1) Dissolve 9g of 2,4-diamino-1,3,5-triazine and 6.5g of cyanuric acid solid powder in 200mL of distilled water, stir at room temperature for 18h and then filter with suction. After drying at ℃ to obtain a graphite phase carbon nitride precursor, grind it for later use; take a few pieces of 1.5×2.5 FTO glass and put them in a beaker, wash them with tap water, ethanol and distilled water for 30 minutes, then dry them with nitrogen, and set them aside;

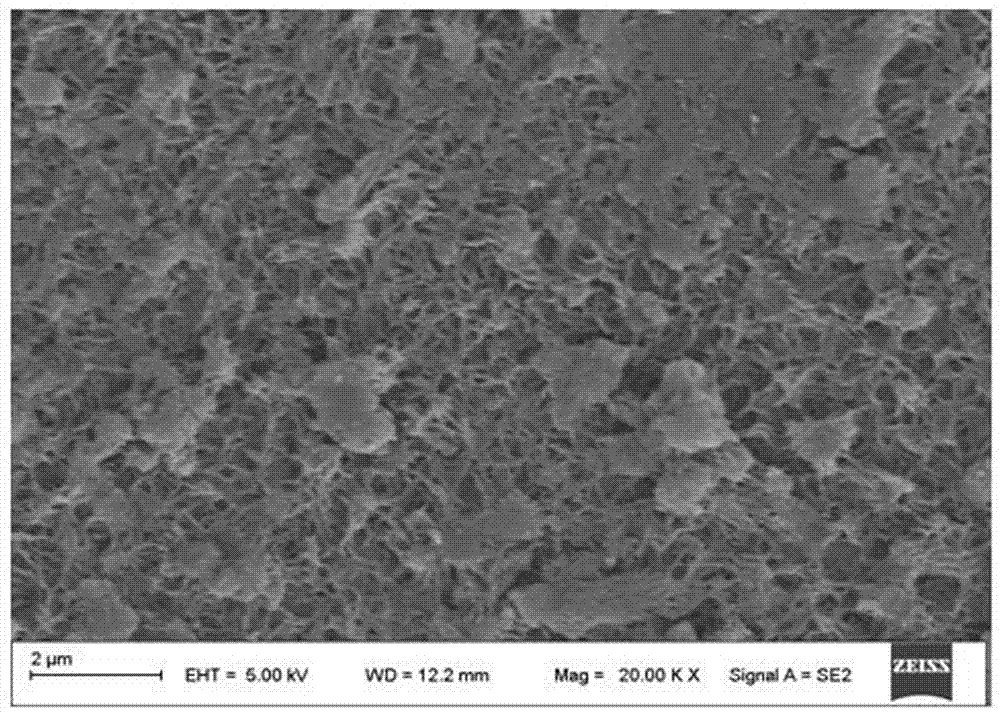

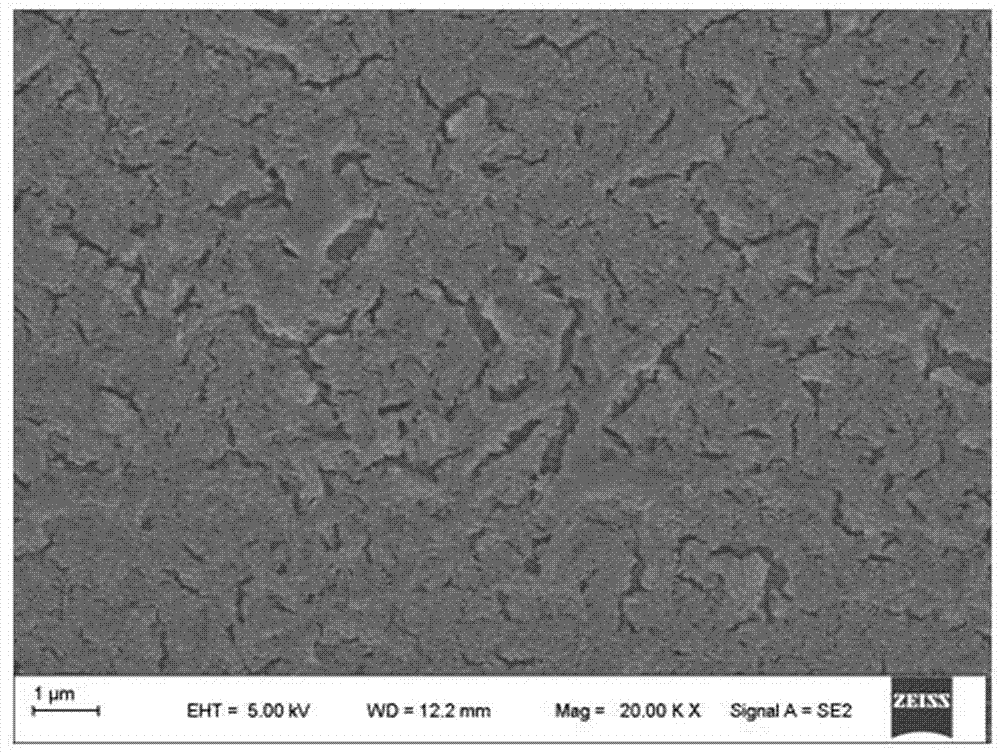

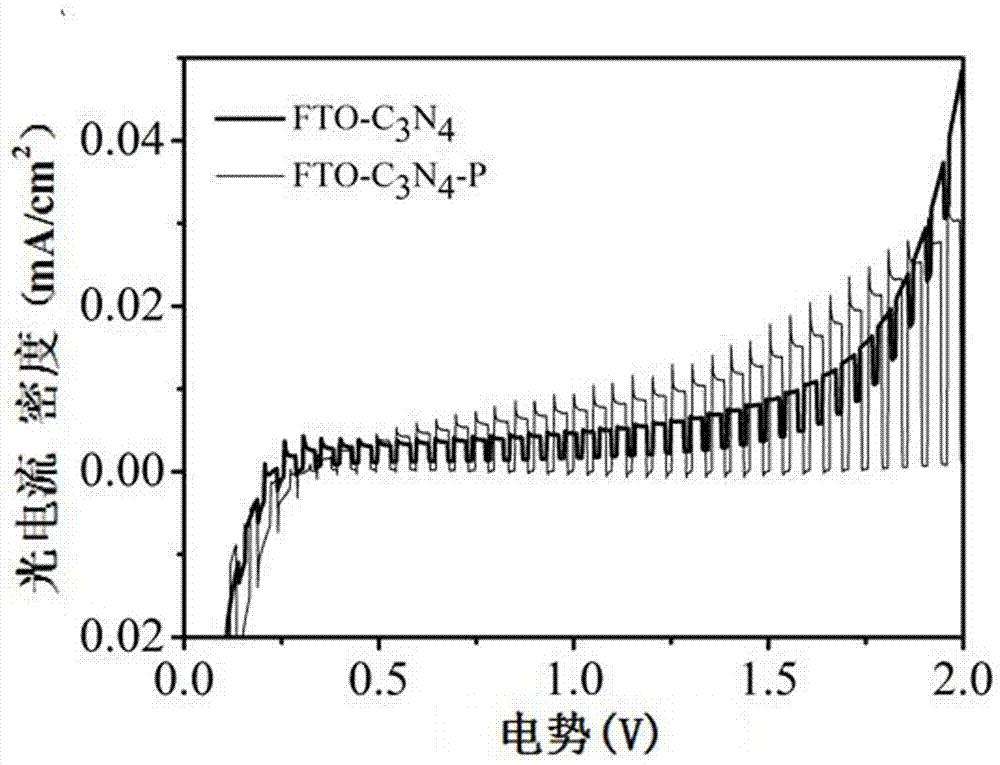

[0023] (2) Put the clean FTO glass conductive side up in the crucible, weigh 1.3g of the graphite-phase carbon nitride precursor powder in step (1), spread it on the FTO glass, and calcinate at 500°C under nitrogen protection 4h, the heating rate was 2.3°C / min, and a yellow graphite phase carbon nitride film was obtained;

[0024] (3) Ultrasonic the graphitic carbon nitride film in step (2) together...

Embodiment 2

[0029] The preparation method of phosphorus-doped graphite phase carbon nitride nano film comprises the following steps:

[0030](1) Dissolve 4.5g of 2,4-diamino-1,3,5-triazine and 3.25g of cyanuric acid solid powder in 100mL of distilled water, stir at room temperature for 18h and then filter with suction. Dry at 70°C to obtain a graphite phase carbon nitride precursor, grind it for later use; use the same method as in Step 1 (1) to clean the FTO glass for later use;

[0031] (2) Put the clean FTO glass conductive side up in the crucible, weigh 1.2g of the graphite phase carbon nitride precursor powder in step (1) and spread it on the FTO glass, and calcined at 520°C under nitrogen protection 4h, the heating rate was 2.4°C / min, and a yellow graphite phase carbon nitride film was obtained;

[0032] (3) Ultrasonic the graphitic carbon nitride film in step (2) together with the FTO glass to remove surface impurities and place it in a magnetic boat placed downstream of the tube ...

Embodiment 3

[0034] The preparation method of phosphorus-doped graphite phase carbon nitride nano film comprises the following steps:

[0035] (1) Dissolve 13.5g of 2,4-diamino-1,3,5-triazine and 9.75g of cyanuric acid solid powder in 300mL of distilled water, stir at room temperature for 24h and then filter with suction. Dry at 60°C to obtain a graphite-phase carbon nitride precursor, grind it for later use; take a few pieces of 1.5×2.5 FTO glass and place them in a beaker, rinse with tap water, ethanol and distilled water for 30 minutes, then blow dry with nitrogen, and set aside; Clean the FTO glass in the same way as in Step 1 (1) for later use;

[0036] (2) Put the clean FTO glass conductive side up in the crucible, weigh 1.0g of the graphite-phase carbon nitride precursor powder in step (1), spread it on the FTO glass, and calcinate at 550°C under nitrogen protection 4h, the heating rate was 2.5°C / min, and a yellow graphite phase carbon nitride film was obtained;

[0037] (3) Ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com