Wave-absorbing material based on vertical micro-porous flexible nonwoven fabric and preparation and application of wave-absorbing material

A microwave-absorbing material and microporous technology, applied in textiles and papermaking, other chemical processes, chemical instruments and methods, etc., can solve the problems of insufficient wave-absorbing attenuation, only passive wave-absorbing, and insufficient wave-absorbing depth, etc., to achieve The effect of light weight, adjustable absorption rate and high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

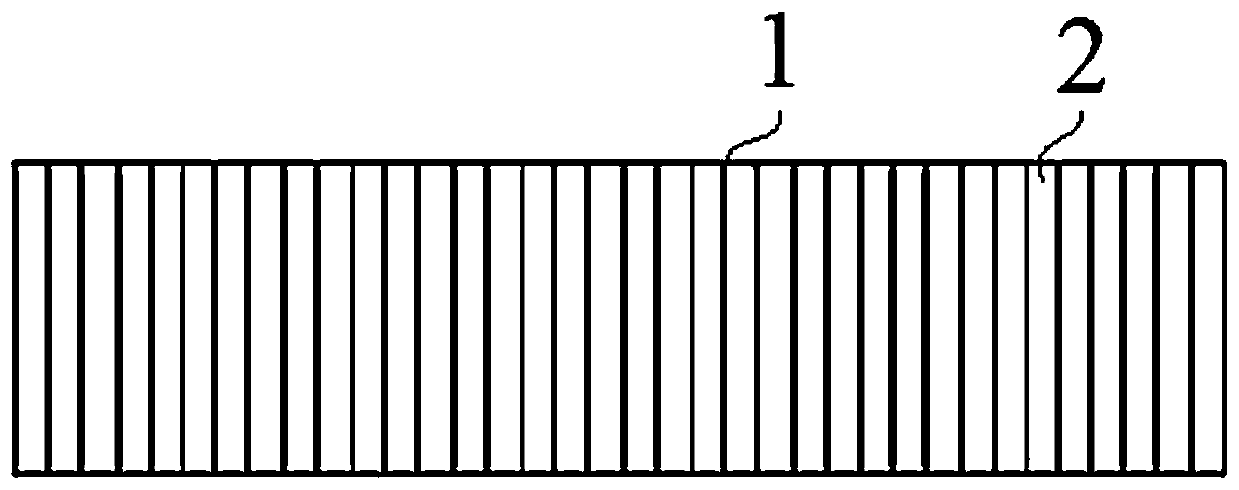

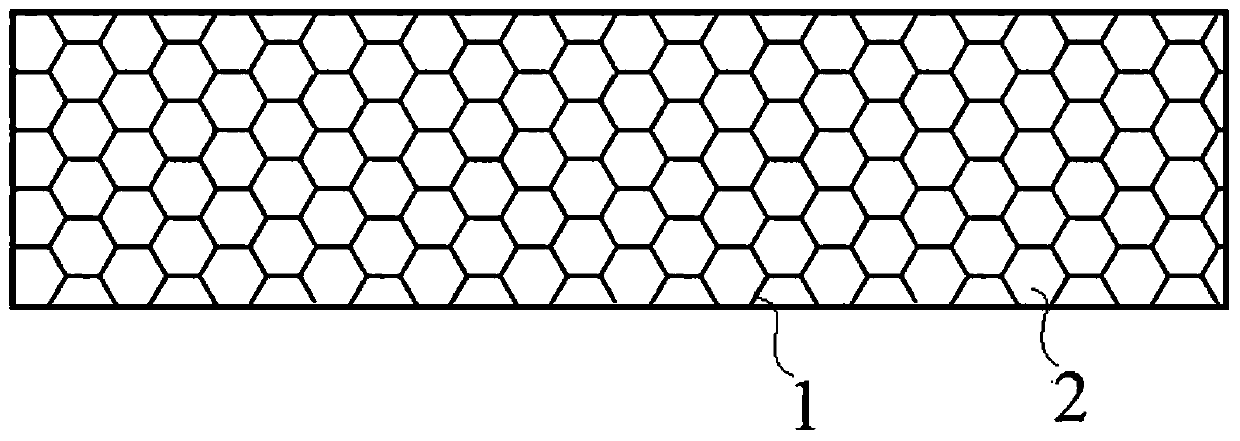

[0058] This embodiment provides a wave-absorbing material based on vertical microporous flexible non-woven fabrics, such as figure 1 and figure 2 As shown, the wave-absorbing material based on vertical microporous flexible nonwoven fabrics includes vertical microporous flexible nonwoven fabrics, and wave-absorbing powder is uniformly adsorbed in the vertical microporous flexible nonwoven fabrics.

[0059] The vertical microporous flexible non-woven fabric includes the fiber body 1 of the network structure arranged vertically and set upright at 90 degrees. The fiber body 1 of the network structure forms uniform and directional pores 2, and the pores 2 are formed from the fiber body. 1 through the communication hole on one side to the other side. The pore 2 is adjustable and controllable, and its shape and size can be set and adjusted according to specific needs, including but not limited to circular, triangular, quadrilateral, pentagonal, hexagonal, etc.

[0060] The vertica...

Embodiment 2

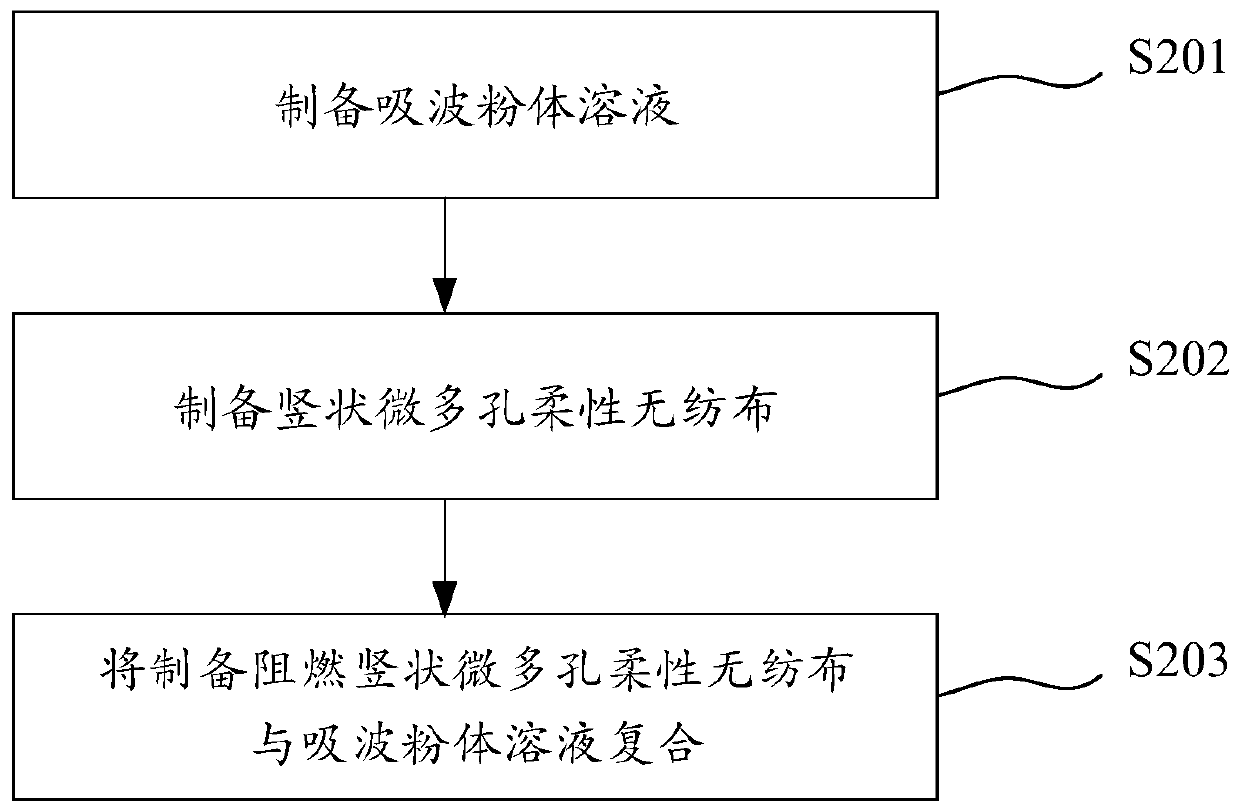

[0095]On the basis of Example 1, this example provides another optional method for preparing a wave-absorbing material based on vertical microporous flexible non-woven fabrics by adjusting the relevant steps and process parameters of the preparation method, including the following steps:

[0096] Step S201: preparing a wave-absorbing powder solution;

[0097] Disperse 5 g of 20-mesh hydroxyl iron, 5 g of binder and 100 g of penetrant in water to form a wave-absorbing powder solution, wherein the solid content of the wave-absorbing powder is 15 wt%.

[0098] Step S202: preparing a flame-retardant vertical microporous flexible non-woven fabric;

[0099] Mix 30wt% PE / PET (polyethylene / polyethylene terephthalate) low-melting fiber with 70wt% flame-retardant polyester fiber, comb it into a web, and then go through a folding web-forming equipment to form a folded Type network structure fiber body, after being heat-treated in an oven at 195°C for 10 minutes, a flame-retardant vertic...

Embodiment 3

[0109] On the basis of Embodiment 1 and Embodiment 2, this embodiment provides a wave-absorbing material with a layered gradient profiled structure.

[0110] Specifically, the plate-shaped wave-absorbing material 10 based on vertical microporous flexible non-woven fabrics in Embodiment 1 is combined with the zigzag-shaped wave-absorbing material 20 based on vertical microporous flexible non-woven fabrics in Example 2. , glued together. The zigzag-shaped wave-absorbing material in the second embodiment is located at the upper part 20, and the plate-shaped wave-absorbing material 10 in the first embodiment is located at the lower part, as Figure 5 As shown, a layered absorbing structure material with gradient and special-shaped appearance structure is formed.

[0111] In addition to the beneficial effects of Embodiment 2, the above-mentioned technical solutions in the embodiments of the present application also have the following technical effects or advantages: they can be cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com