Porous capsule noise reduction and sound insulation material as well as preparation method and application thereof

A technology of sound insulation materials and porous capsules, applied in applications, other household appliances, noise absorption devices, etc., can solve the problems of high cost of metal sound barriers, easy corrosion of metal, poor sound absorption performance, etc., to reduce segregation and leakage Effect of water, impermeability improvement, pore size refinement and homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

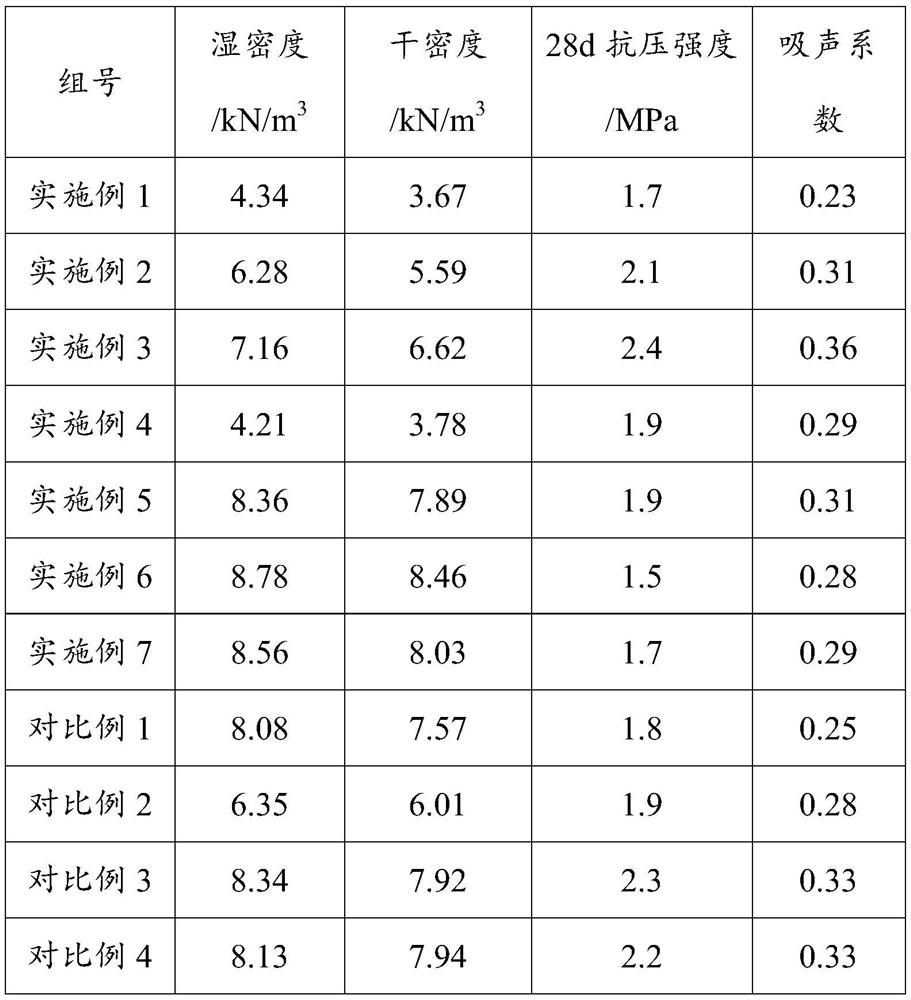

Examples

Embodiment 1

[0041] 1) Take 30 parts of Bayer red mud, 30 parts of S95 grade mineral powder, 15 parts of F class fly ash, 15 parts of 3.3M water glass, 6 parts of FP-186 foaming agent, 1.5 parts of calcium stearate, poly 2.5 parts of vinyl fiber, the water-binder ratio is 0.65;

[0042] 2) the Bayer process red mud, the S95 grade mineral powder, the F class fly ash, the 3.3M water glass, the calcium stearate, the polyethylene fiber and water (water cement ratio 0.65) into the mixer and stirred for 90s to obtain the slurry;

[0043] 3) Dilute the FP-186 foaming agent and water at a ratio of 1:60 to make a diluent, and pressurize it through a foaming machine to prepare bubbles;

[0044] 4) Transport the foam to the mixer, stir it for 90 seconds, pour it into the mold for molding, remove the mold after 48 hours, cover it with plastic film, put it in the standard curing room for 28 days, and test the performance of the porous capsule noise reduction and sound insulation material .

Embodiment 2

[0046] 1) Take 40 parts of Bayer red mud, 40 parts of P.O 42.5 ordinary Portland cement, 10 parts of desulfurized gypsum, 5.5 parts of FP-186 foaming agent, 1.5 parts of calcium stearate, 2.5 parts of polyethylene fiber, phosphate 0.5 parts of retarder, the water-binder ratio is 0.75;

[0047] 2) the Bayer method red mud, the P.O 42.5 ordinary Portland cement, the desulfurized gypsum, the calcium stearate, the polyethylene fiber, the phosphate retarder and water (water gel Ratio is 0.75) poured into the mixer and stirred for 90s to obtain the slurry;

[0048] 3) Dilute the FP-186 foaming agent and water at a ratio of 1:40 to make a diluent, and pressurize it through a foaming machine to prepare bubbles;

[0049] 4) Transport the foam to the mixer, stir it for 60 seconds and pour it into the mold to form it. After 48 hours, remove the mold, cover it with plastic film, put it in the standard curing room for 28 days, and test the performance of the porous capsule noise reduction...

Embodiment 3

[0051] 1) Take 36 parts of Bayer red mud, 55 parts of ordinary Portland cement with P.O 42.5, 5.3 parts of FP-186 foaming agent, 1.2 parts of hydroxypropyl methylcellulose ether, 2.5 parts of polyethylene fiber, and the water-cement ratio is 0.6;

[0052] 2) Pour the Bayer process red mud, the P.O 42.5 ordinary Portland cement, the hydroxypropyl methylcellulose ether, the polyethylene fiber and water (the water-binder ratio is 0.6) into a mixer and stir 90s to obtain slurry;

[0053]3) Dilute the FP-186 foaming agent and water at a ratio of 1:60 to make a diluent, and pressurize it through a foaming machine to prepare bubbles;

[0054] 4) Transport the foam to the mixer, stir it for 90 seconds, pour it into the mold for molding, remove the mold after 48 hours, cover it with plastic film, put it in the standard curing room for 28 days, and test the performance of the porous capsule noise reduction and sound insulation material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com