Antibacterial hygienic material made from bamboo proto fibers and manufacturing process and application thereof

A technology of raw bamboo fiber and hygienic materials, which is applied in the field of antibacterial hygienic materials, can solve the problems of waste cotton no longer satisfying opening, carding processing, insufficient utilization, and high impurity content, so as to prevent human body from being infringed again, save resources, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] When the raw material adopts 30-60% waste bamboo fiber or bamboo fiber or a mixture of waste bamboo fiber and bamboo fiber, 10-60% viscose fiber, 0-30% polyester fiber, 8-12% The hot-melt fiber is used as the raw material, and its specific components are as follows (more than three):

[0041] Ingredient one:

[0042]30kg of "short and thin" waste bamboo fiber and 15kg of "short and thin" waste cotton fiber or 15kg of "short and thin" bamboo fiber are mixed;

[0043] 10kg of ES hot-melt fiber;

[0044] 30kg of polyester fiber;

[0045] 15kg of viscose fiber;

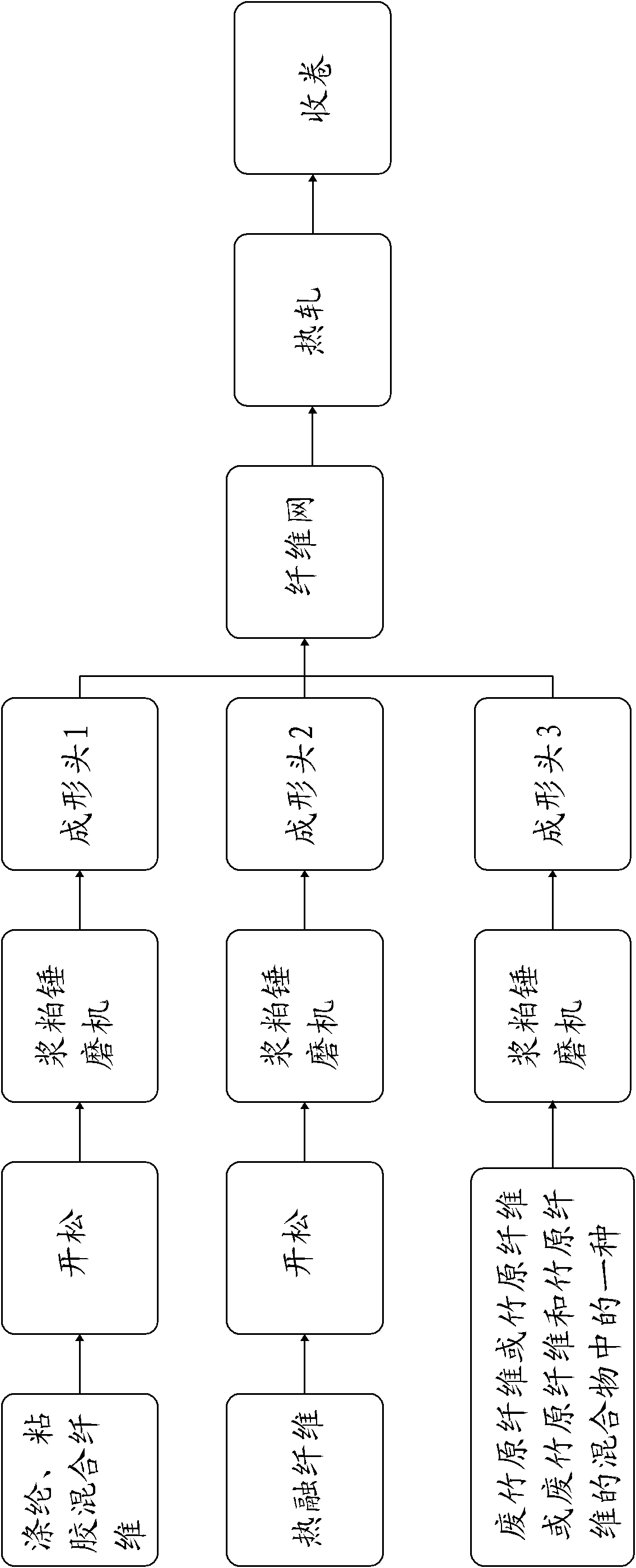

[0046] Such as figure 1 As shown, the specific steps of its manufacturing process are as follows:

[0047] Step 11, mix the polyester fiber of 30kg and the viscose fiber of 15kg, open through the opener, the roll speed of the opener is set to 980r / min, then send into the pulp hammer mill to loosen the fiber, The rotary speed of the pulp hammer mill is set at 2800r / min, further ground into loose short fibers, ...

Embodiment 2

[0075] When the raw material adopts 30-60% waste bamboo fiber or bamboo fiber or a mixture of waste bamboo fiber and bamboo fiber, 10-60% viscose fiber, 0-30% polyester fiber, 8-12% The hot-melt powder is used as the raw material, and its specific components are as follows (more than three):

[0076] Ingredient one:

[0077] 30kg of "short and thin" waste bamboo fiber and a mixture of "short and thin" bamboo fiber;

[0078] 10kg of hot-melt powder;

[0079] 30kg of polyester fiber;

[0080] 30kg of viscose fiber;

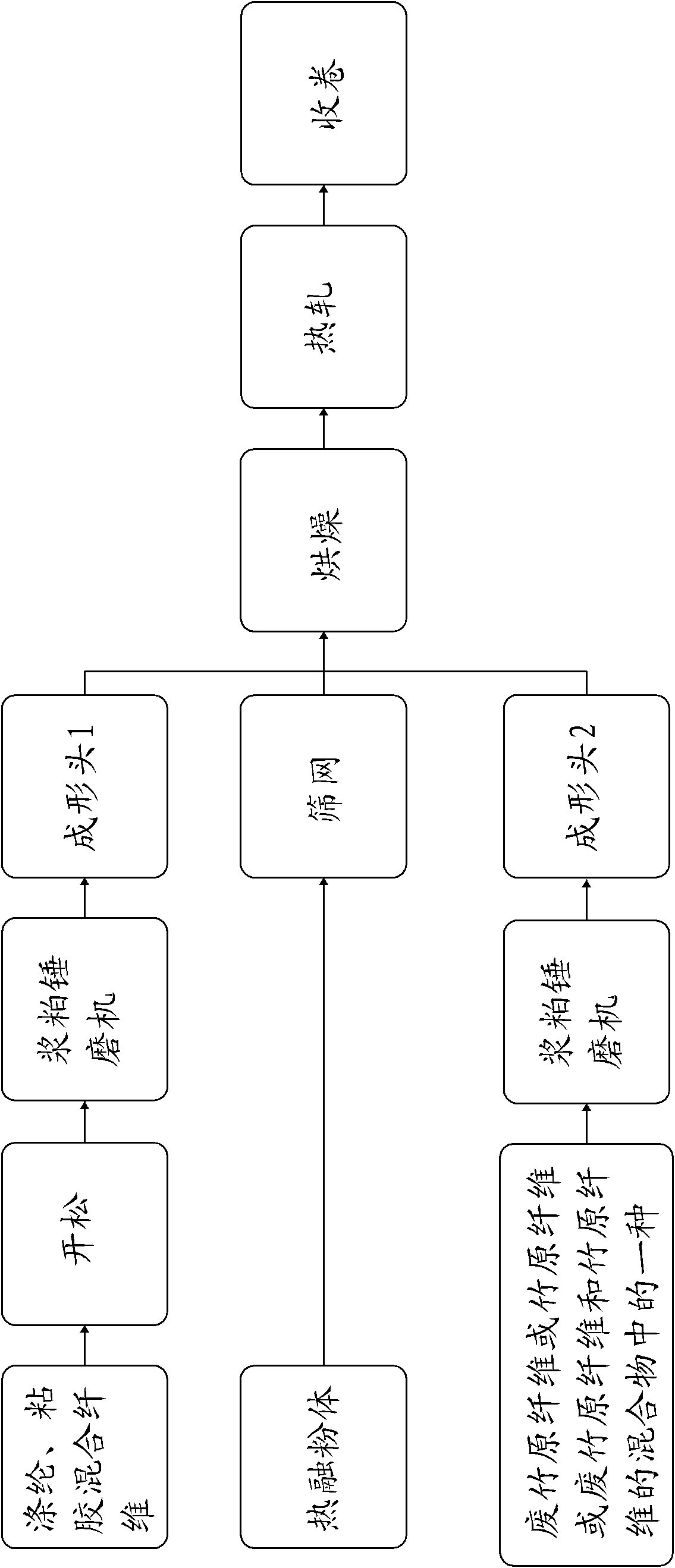

[0081] Such as image 3 As shown, the specific steps of its manufacturing process are as follows:

[0082] Step 41, mix 30kg of polyester fiber and 30kg of viscose fiber, open through an opener, the roller speed of the opener is set to 980r / min, and then send it into a pulp hammer mill to loosen the fiber, The rotary speed of the pulp hammer mill is set at 2800r / min, further ground into loose short fibers, and sent to the forming head to form the first net;

...

Embodiment 3

[0110] When the raw material adopts 30-60% waste bamboo fiber or bamboo fiber or a mixture of waste bamboo fiber and bamboo fiber, 10-60% viscose fiber, 0-30% polyester fiber, 8-12% Latex is used as a raw material, and its specific components are as follows (more than three) in three situations:

[0111] Ingredient one:

[0112] 30kg of "short and thin" waste bamboo fibers;

[0113] 30kg of polyester fiber;

[0114] 28kg of viscose fiber;

[0115] Such as Figure 4 As shown, the specific steps of its manufacturing process are as follows:

[0116] Step 71, mix 30kg of polyester fibers and 28kg of viscose fibers, and open them through an opener, the roller speed of which is set at 980r / min, and send them into a pulp hammer mill to loosen the fibers. Further ground into loose short fibers, sent to the forming head to form the first net;

[0117] Step 72, 30kg of "short and thin" waste bamboo raw fibers are loosened by a pulp hammer mill, ground into loose and extremely shor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com