Polyester viscous cotton interweaving method

A technology of polyester-viscose cotton and viscose, which is applied in the field of polyester-viscose-cotton interweaving, which can solve the problems of uncomfortable wearing of polyester-cotton fabrics, poor coloring rate of silk-cotton fabrics, and easy fluffing of viscose-cotton fabrics, etc., to achieve good hand feeling and strong three-dimensional effect , the effect of not easy to fluff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

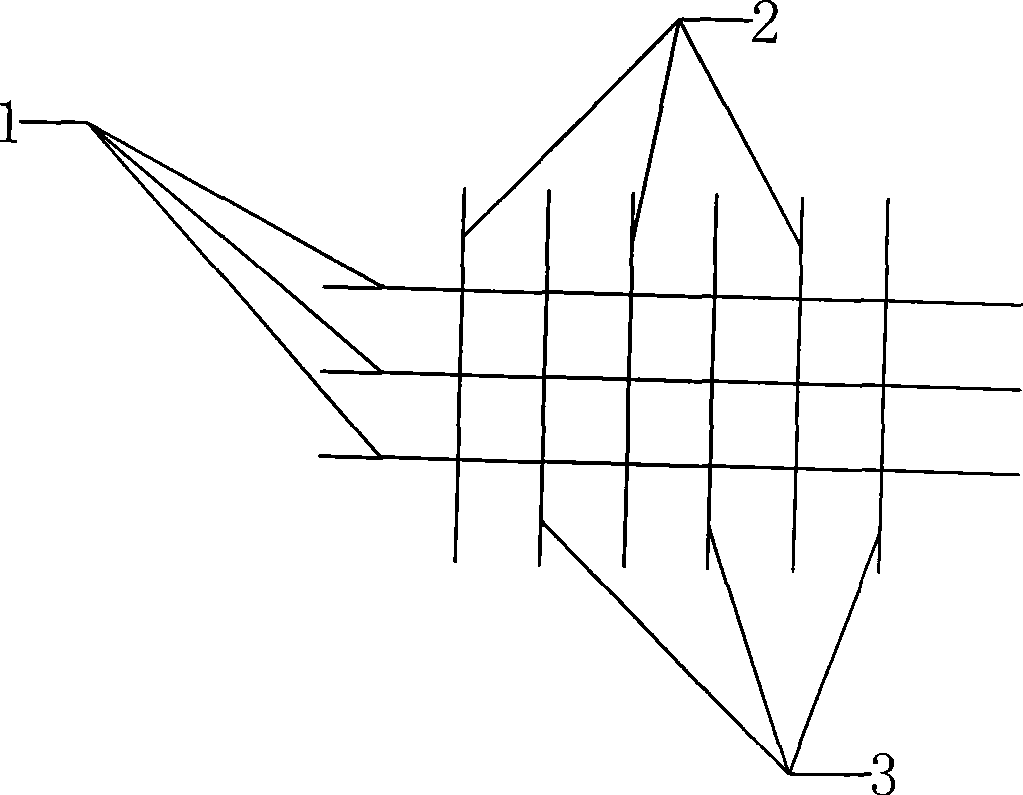

[0012] Such as figure 1 As shown, the viscose-cotton interweaving method in this embodiment adopts a single warp and double weft structure, and the warp thread 1 adopts 40, 50 or 60 cotton yarns; the weft thread adopts odd and even alternating, and the odd row weft thread 2 adopts DTY has light filament, even-numbered weft thread 3 is made of viscose rayon 150D; warp thread 1 is interlaced vertically with odd-numbered weft thread 2, even-numbered weft thread 3, and the three raw materials are ordered through the weaving CAD system Combination, the three warp and weft materials are arranged in different weaves, and the warp thread 1 at the weaving point is pressed on the odd row of weft thread 2, the even row of weft thread 3 or the odd row of weft thread 2, the even row of weft The direction thread 3 is pressed on the warp thread 1 and organized and arranged according to certain rules to form different patterns and visual effects; the single warp and double weft structure fabric c...

Embodiment 2

[0014] The viscose-cotton interweaving method in this embodiment adopts a structure of single warp and double weft. The warp thread 1 adopts 40, 50 or 60 cotton yarns; the weft thread adopts odd and even alternating, and the weft thread 2 of odd rows adopts FTY shiny yarn. , The even-numbered weft thread 3 uses viscose rayon 150D; the warp-direction thread 1 is interlaced vertically with the odd-numbered weft thread 2, the even-numbered weft thread 3, and the three raw materials are combined in an orderly manner through the weaving CAD system. The warp and weft materials are arranged in different weaves. The warp thread 1 at the weaving point is pressed on the odd-numbered weft thread 2, the even-numbered weft thread 3 or the odd-numbered weft thread 2, the even-numbered weft thread 3 is pressed On the warp threads 1, they are organized and arranged according to certain rules to form different patterns and visual effects; the fabric with single warp and double weft structure after...

Embodiment 3

[0016] The viscose-cotton interweaving method described in this embodiment adopts a single warp and double weft structure. The warp thread 1 adopts 40, 50 or 60 cotton yarns; the weft thread adopts odd-even alternating, and the odd-numbered weft thread 2 adopts DTY shiny yarn. , The even-numbered weft thread 3 is made of viscose rayon 120D; the warp-direction thread 1 is interlaced vertically with the odd-numbered weft thread 2, the even-numbered weft thread 3, and the three materials are combined in an orderly manner through the weaving CAD system. The warp and weft materials are arranged in different weaves. The warp thread 1 at the weaving point is pressed on the odd-numbered weft thread 2, the even-numbered weft thread 3 or the odd-numbered weft thread 2, the even-numbered weft thread 3 is pressed On the warp threads 1, they are organized and arranged according to certain rules to form different patterns and visual effects; the fabric with single warp and double weft structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com