Polypropylene non-woven fabric soft master batch material as well as preparation method and application thereof

A polypropylene non-woven fabric and soft masterbatch technology, which is applied in textiles and papermaking, single-component polyolefin rayon, non-woven fabrics, etc., can solve the problem of high addition of polypropylene fiber soft masterbatch and complicated process flow , poor softening effect and other problems, to avoid long screen changing cycle, shorten the process flow, and achieve the effect of high bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

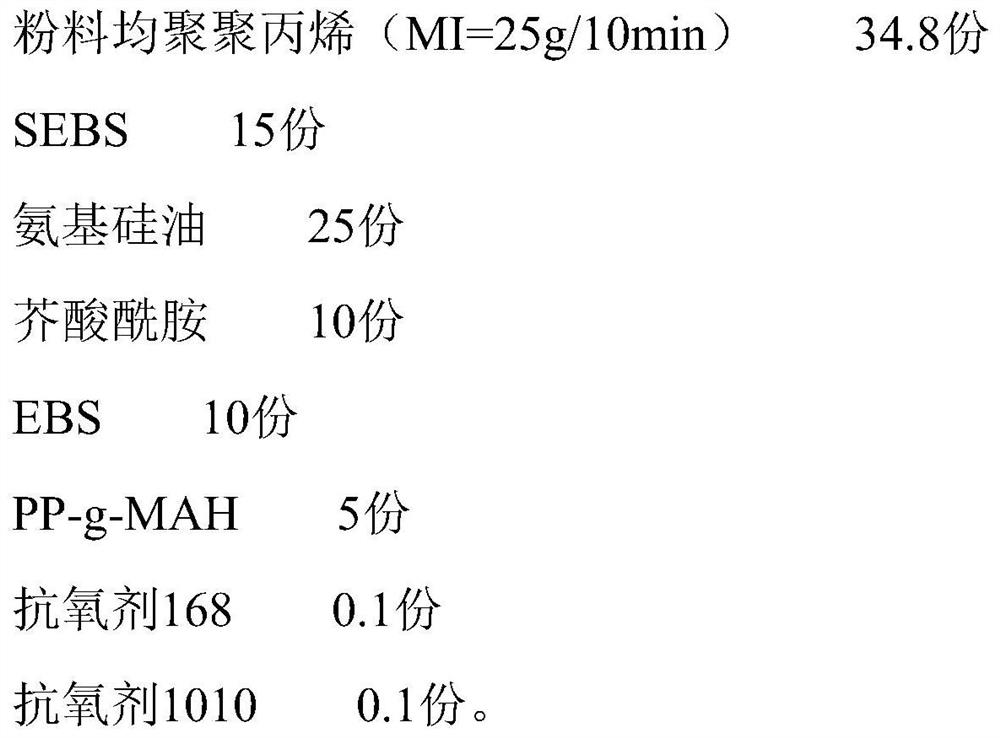

Embodiment 1

[0038] The preparation method of polypropylene non-woven soft masterbatch material: add styrene type block copolymer and silicone type softener to a high-speed mixer and stir, make them fully mixed, and then let stand until the silicone type softener is removed. After complete absorption, add polypropylene, compatibilizer and antioxidant to it for stirring and mixing, and finally add lubricating softener. After mixing evenly, it was transferred to an extruder with a length-diameter ratio of 48 twin-screw and a total of 12 barrels for melt extrusion and granulation. The barrel temperature is set as follows: the second barrel temperature is 135°C, the third barrel temperature is 210°C, the fourth barrel temperature is 200°C, the fifth barrel temperature is 200°C, and the sixth barrel temperature is 200°C. The barrel temperature is 190°C, the seventh barrel temperature is 190°C, the eighth barrel temperature is 185°C, the ninth barrel temperature is 185°C, the tenth barrel temper...

Embodiment 2

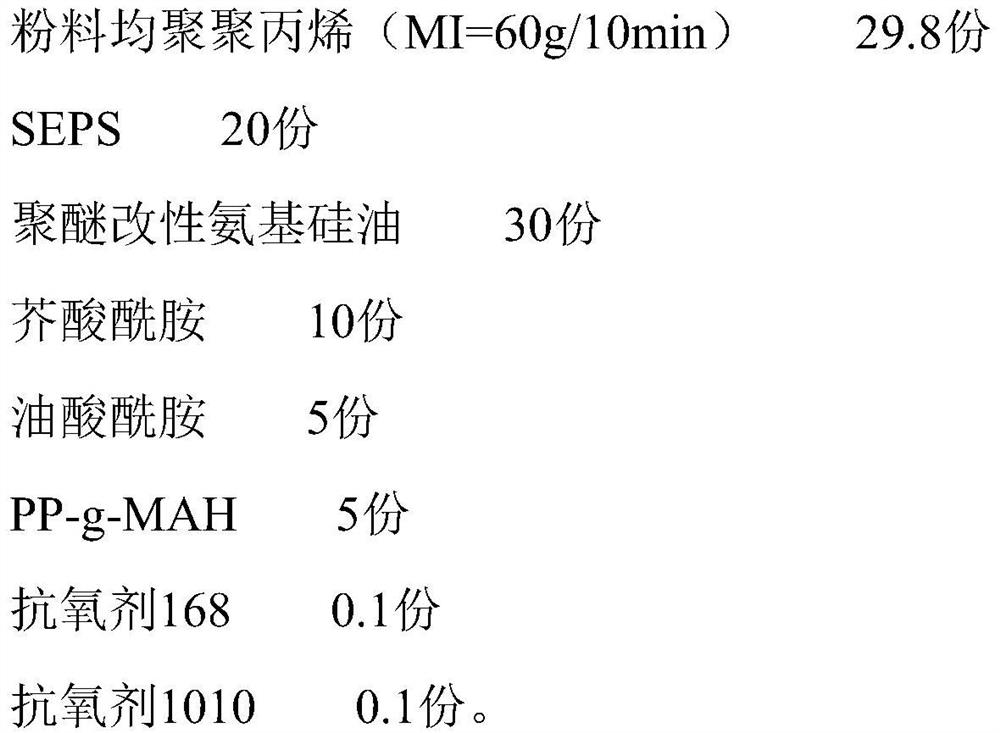

[0042]Carry out the preparation of polypropylene non-woven fabric soft master batch material according to the processing method of embodiment 1, compared with embodiment 1, the difference is: the parts by weight of each component are as follows:

[0043]

Embodiment 3

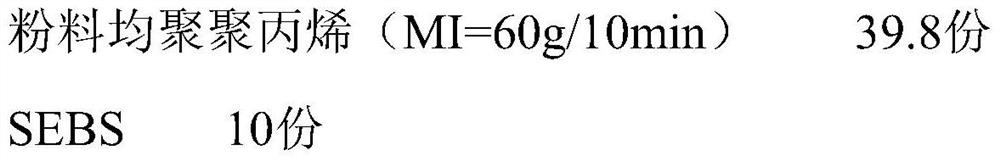

[0045] Carry out the preparation of polypropylene non-woven fabric soft master batch material according to the processing method of embodiment 1, compared with embodiment 1, the difference is: the parts by weight of each component are as follows:

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com