Natural dye dying method based on cotton fiber modification

A technology of natural dyes and dyeing methods, which is applied to the preparation of cotton fiber modified liquid, the application of natural dye dyeing technology, and the field of natural dye dyeing of cotton fibers, which can solve the problems of poor color fastness and low dyeing rate, and achieve Easy to operate, uniform dyeing, and the effect of improving the dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment selects cotton fabric to carry out dyeing treatment, and concrete steps are as follows:

[0024] (1) Cationic modified liquid treatment

[0025] The formula of the cationic modifier solution is as follows: the dosage of cationic modifier is 15 g / liter, the bath ratio is 1:20, the cotton fabric is treated for 10 minutes at room temperature, and then the temperature is raised to 70 DEG C at a heating rate of 2 DEG C / min, and the 4 g / L caustic soda, treated at 70°C for 60 minutes, after modification, wash the fabric with cold water.

[0026] (2) Dyeing with natural dyes

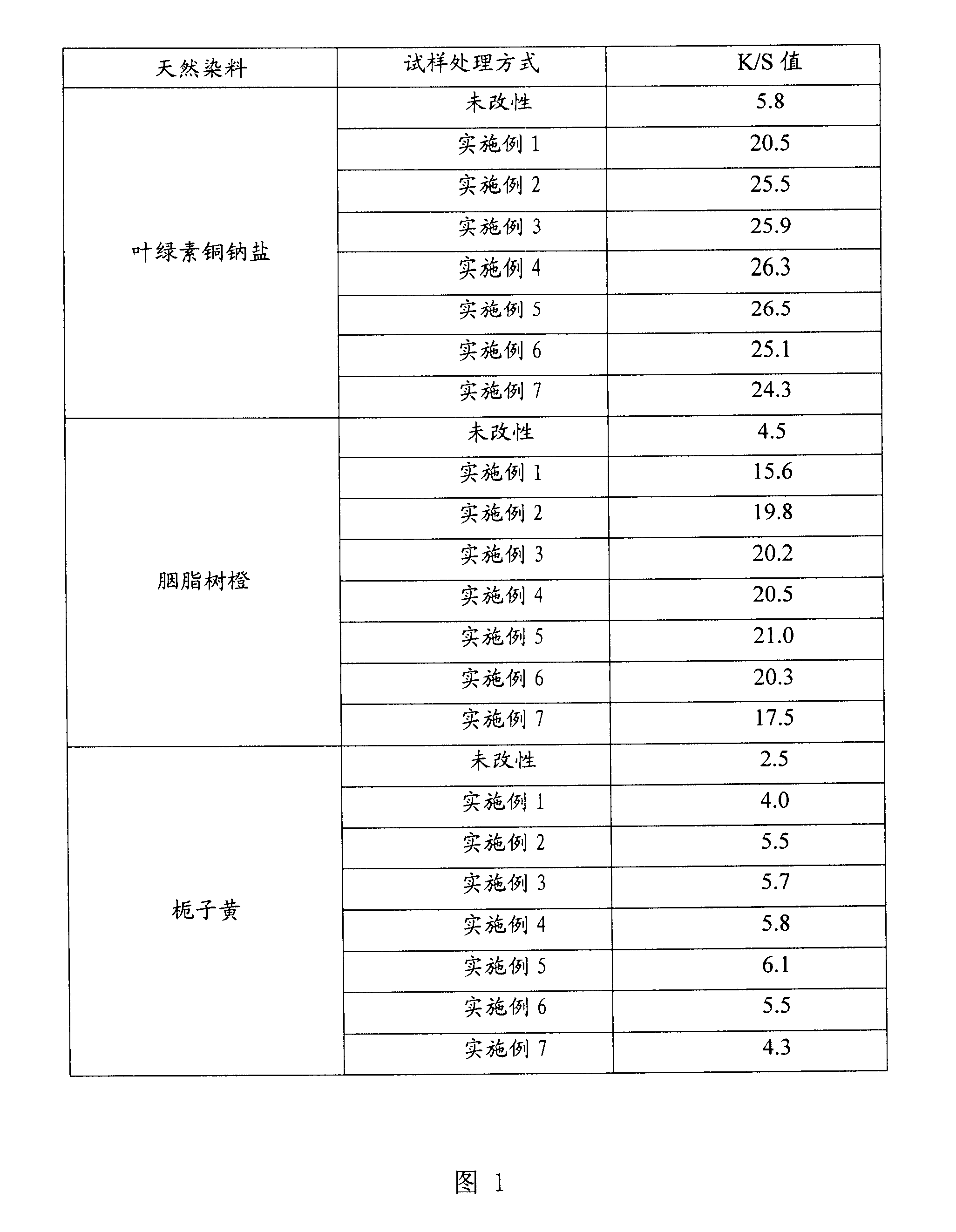

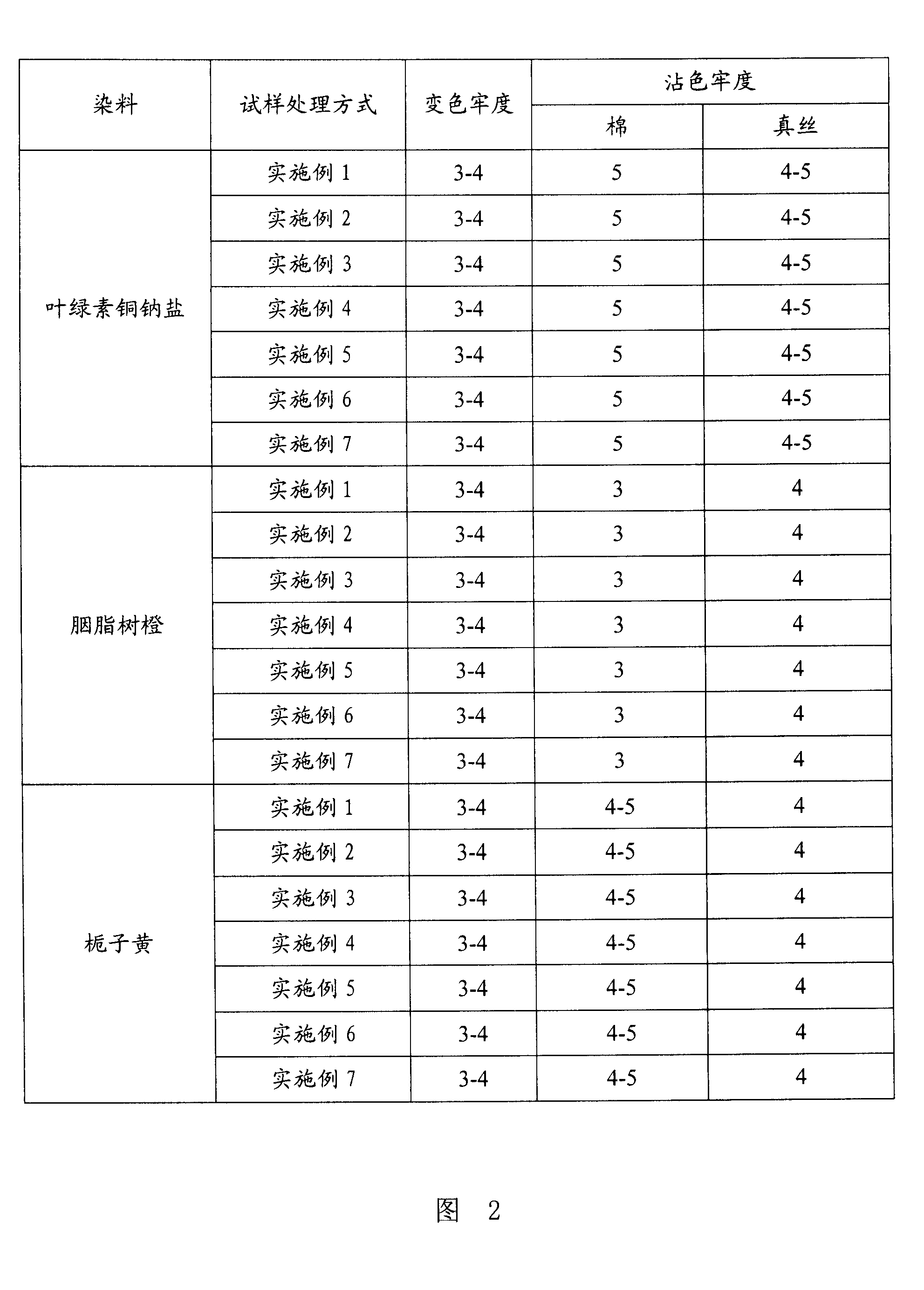

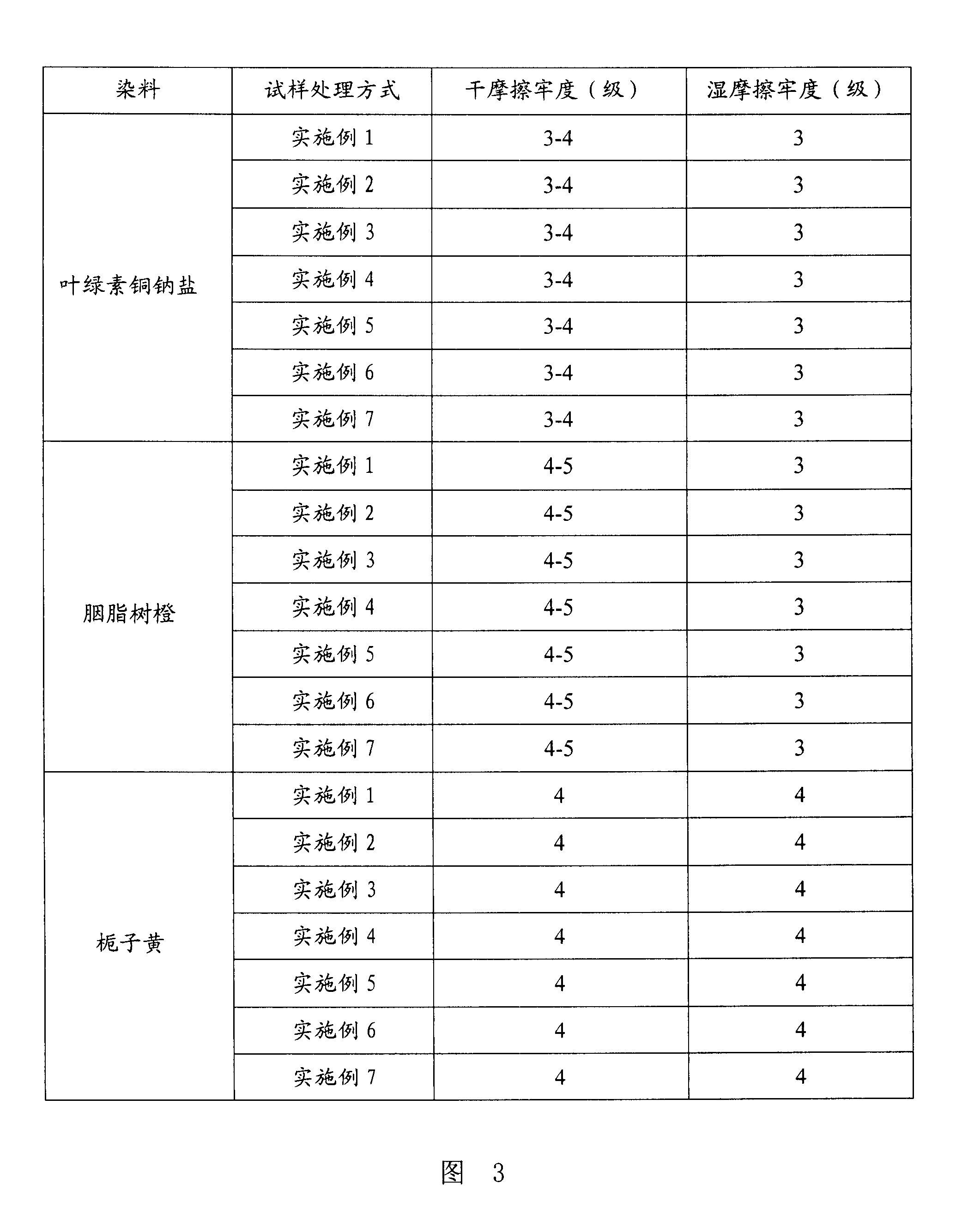

[0027] Cotton fabrics treated with the above cationic modification solution were dyed with natural dyes copper sodium chlorophyllin, annatto and gardenia yellow; at the same time, the same dyeing process was used to dye the cotton fabric without cationic modification solution as it was deal with. The formula of the dyeing solution is: the weight percent concentration (o.w.f) of t...

Embodiment 2

[0029] (1) Cationic modified liquid treatment

[0030] The formula of the cationic modifier solution is as follows: the cationic modifier dosage is 18 g / L, the bath ratio is 1:20, the cotton fabric is treated for 5 minutes at room temperature, and then the temperature is increased to 70 DEG C at a heating rate of 2 DEG C / min, and the 5 g / L caustic soda, treated at 70°C for 60 minutes, after modification treatment, wash the fabric with cold water.

[0031] (2) Dyeing with natural dyes

[0032] Cotton fabrics treated with the above cationic modification solution were dyed with natural dyes copper sodium chlorophyllin, annatto and gardenia yellow; at the same time, the same dyeing process was used to dye the cotton fabric without cationic modification solution as it was deal with. The formula of the dyeing solution is: the weight percent concentration (o.w.f) of the dye relative to the fabric is 2%, the bath ratio is 1:20, at room temperature, the cotton fabric treated with the...

Embodiment 3

[0034] (1) Cationic modified liquid treatment

[0035] The formula of the cationic modifier solution is as follows: the cationic modifier dosage is 21 g / liter, the bath ratio is 1:20, the cotton fabric is treated for 5 minutes at room temperature, and then the temperature rises to 70 DEG C at a heating rate of 2 DEG C / min, adding 6 g / L caustic soda, treated at 70°C for 60 minutes, after modification treatment, wash the fabric with cold water.

[0036] (2) Dyeing with natural dyes

[0037] Cotton fabrics treated with the above cationic modification solution were dyed with natural dyes copper sodium chlorophyllin, annatto and gardenia yellow; at the same time, the same dyeing process was used to dye the cotton fabric without cationic modification solution as it was deal with. The formula of the dyeing solution is: the weight percent concentration (o.w.f) of the dye relative to the fabric is 2%, the bath ratio is 1:20, at room temperature, the cotton fabric treated with the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com