Photosensitive composite fabric

A composite fabric and photosensitive technology, applied to synthetic resin layered products, clothing, protective clothing, etc., can solve the problems of complex treatment process, poor washability and effect, and many wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

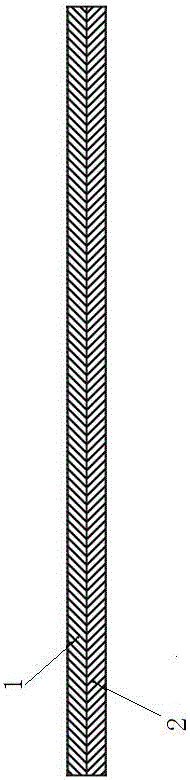

[0011] Such as figure 1 As shown, in the photosensitive composite fabric of the present invention, the composite fabric is composed of a comfortable fabric layer (1) and a photosensitive fabric layer (2) from the inside to the outside; the comfortable fabric layer (1) is composed of nylon fiber and polyester fiber Woven with cotton fiber blended yarn, the photosensitive fabric layer (2) is woven from photosensitive composite fibers, the photosensitive composite fibers are sheath-core composite fibers, the photosensitive color-changing fiber is used as the core layer, and the polyester fiber is used as the core layer. The ratio of the diameter of the skin layer and the core layer to the total diameter of the composite fiber is 4:10. The weight percentages of nylon fiber, polyester fiber and cotton fiber in the comfortable fabric layer (1) are 10%, 80% and 10% respectively.

Embodiment 2

[0013] The structure of the photosensitive composite fabric of the present invention is the same as that of Example 1. The composite fabric is composed of a comfortable fabric layer (1) and a photosensitive fabric layer (2) from the inside to the outside; the comfortable fabric layer (1) is made of nylon Fiber, polyester fiber and cotton fiber blended yarn, said photosensitive fabric layer (2) is woven from photosensitive composite fiber, said photosensitive composite fiber is a sheath-core composite fiber, with photosensitive color-changing fiber as the core layer, Using polyester fiber as the skin layer, the ratio of the core layer diameter to the total diameter of the composite fiber is 8:10. The weight percentages of nylon fiber, polyester fiber and cotton fiber in the comfortable fabric layer (1) are 10%, 80% and 10% respectively.

Embodiment 3

[0015] The structure of the photosensitive composite fabric of the present invention is the same as that of Example 1. The composite fabric is composed of a comfortable fabric layer (1) and a photosensitive fabric layer (2) from the inside to the outside; the comfortable fabric layer (1) is made of nylon Fiber, polyester fiber and cotton fiber blended yarn, said photosensitive fabric layer (2) is woven from photosensitive composite fiber, said photosensitive composite fiber is a sheath-core composite fiber, with photosensitive color-changing fiber as the core layer, With polyester fiber as the skin layer, the ratio of core layer diameter to total composite fiber diameter is 9:10. The weight percentages of nylon fiber, polyester fiber and cotton fiber in the comfortable fabric layer (1) are 10%, 80% and 10% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com