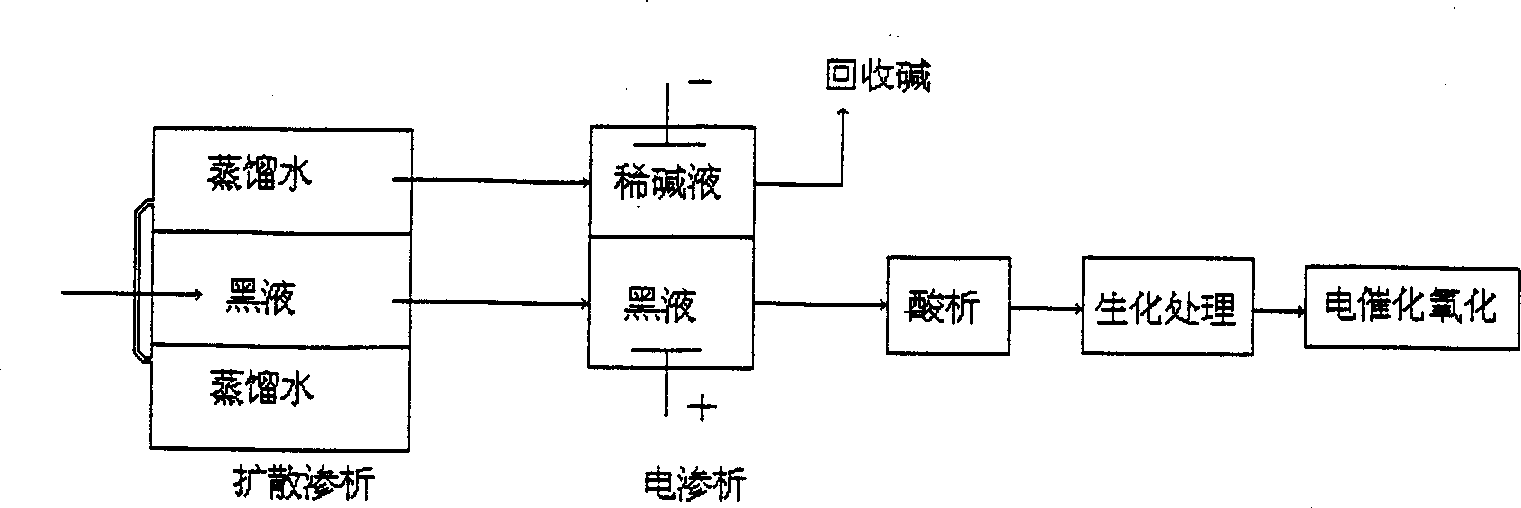

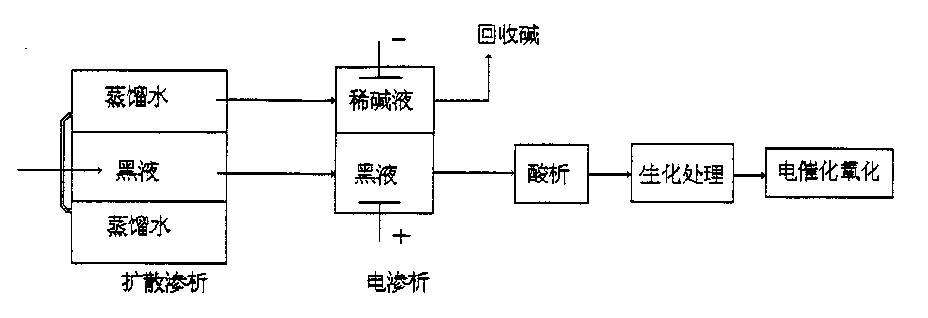

Alkali recovery process for black liquor of straw pulp

A straw pulp black liquor and new process technology, applied in the field of environmental technology and electrochemistry, can solve the problems of limited application range, difficult anode materials, easy wear and tear, etc., and achieve the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

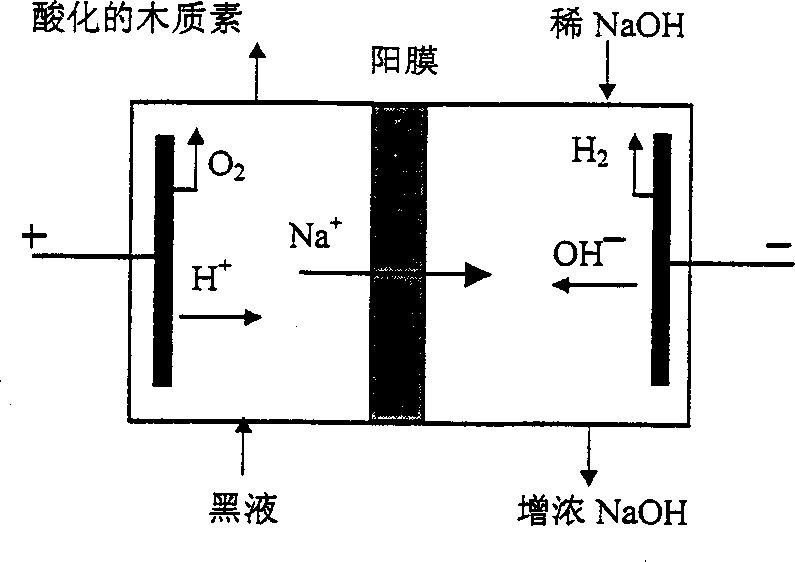

Method used

Image

Examples

Embodiment 1

[0015] In the case of electronic peristaltic pump enhanced circulation, the black liquor is firstly subjected to ion exchange membrane diffusion dialysis for 100 minutes. The dilute lye obtained is used as the electrolyte in the cathodic chamber of the electrodialysis process, and the black liquor treated by diffusion dialysis is used as the electrolyte in the anode chamber of the electrodialysis. The electrolysis is performed at a constant current of 1A for 120 minutes, and the distance between the cathode and the anode is 2 cm. The results are shown in Table 1.

[0016]

project

Raw black liquor

Diffusion dialysis

100min

Diffusion dialysis

100min

120min

CODCr(mg / L)

37675.2

32400.67

Removal rate 14.0%

36582.20

Removal rate 29.7%

Na + (g / L)

7.68

6.996

Recovery rate 8.9%

3.504

Recovery rate 54.4%

[0017] It can be seen fro...

Embodiment 2

[0021] In the case of enhanced circulation by electronic peristaltic pump, the black liquor is firstly subjected to diffusion dialysis by hydrophobic fluorine membrane for 100 minutes. The dilute lye obtained is used as the electrolyte in the cathodic chamber of the electrodialysis process, and the black liquor treated by diffusion dialysis is used as the electrolyte in the anode chamber of the electrodialysis. The electrolysis is performed at a constant current of 1A for 120 minutes, and the distance between the cathode and the anode is 2 cm. The results are shown in Table 2.

[0022]

[0023] It can be seen from the figure that after the black liquor undergoes diffusion dialysis, the COD Cr The removal rate was 16.3%, and the recovery rate of NaOH was 13.4%. After combined treatment with electrodialysis, about 59.3% of NaOH was recovered. + , and has a COD of 31.1% Cr removal rate.

Embodiment 3

[0025] In the case of electronic peristaltic pump enhanced circulation, the black liquor is firstly subjected to diffusion dialysis of hydrophilic fluorine membrane for 100 minutes. The dilute lye obtained is used as the electrolyte in the cathodic chamber of the electrodialysis process, and the black liquor treated by diffusion dialysis is used as the electrolyte in the anode chamber of the electrodialysis. The electrolysis is performed at a constant current of 1A for 120 minutes, and the distance between the cathode and the anode is 2 cm. The results are shown in Table 3.

[0026]

project

Diffusion dialysis

100min

Diffusion dialysis

100min

120min

Remark

COD Cr (mg / L)

37675.2

31182.24

Removal rate 17.2%

25170.24

Removal rate 33.19%

Na + (g / L)

7.68

6.530

Recovery rate 15.0%

3.052

Recovery rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com