Novel cellulose extraction process

A cellulose and crude cellulose technology, applied in the multi-stage pulping process, fiber raw material processing, digester and other directions, can solve the problems of large consumption of raw materials in the extraction process, low cellulose extraction rate, destruction of effective components, etc., and achieve low odor. , good growth, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

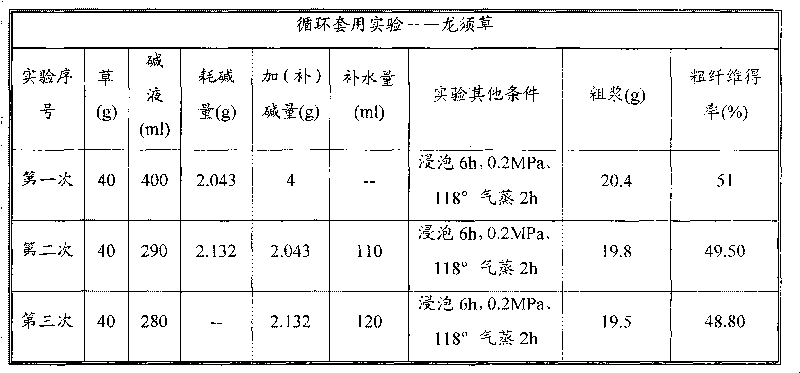

[0041] Example 1 (Pulping of Alpine grass)

[0042] Soak 300g of Longxu grass (moisture 10.2%) in 3000ml 1.0% NaOH solution for 6 hours and then filter it out, put it in a beaker and place it in a pressure cooker at 0.2MPa, 118°C for 2 hours after steaming, take it out and polish it. The pulp is washed, filtered, and dried to constant weight at 105°C to obtain 144 g of crude cellulose. The cellulose yield is 48%, and the cellulose extraction rate is above 95%. Crude cellulose beating, papermaking and forming operations, and finally the paper performance is tested. The paper properties are as follows: tensile index 38.86N.m / g, tear index 15.77mN.m 2 / g, burst resistance index 4.03kPa×m 2 / g, the folding endurance is 49 times.

Embodiment 2

[0043] Example 2 (Pulping of Longxugrass)

[0044] Add 300g of Alpine (moisture 10.2%), about 2500ml of the remaining soaking solution in Example 1 (residual alkali content is about 0.65%) to 3000ml 1.0% NaOH solution, soak for 6 hours, and then filter out. Put it into the container and place it in a pressure cooker at 0.2MPa, 118℃, steam for 2 hours, take it out, polish, wash the pulp, filter out, and bake at 105℃ to constant weight, get 149.4g crude cellulose, cellulose yield Is 49.8%. Crude cellulose beating, papermaking and forming operations, and finally the paper performance is tested. The paper properties are as follows: tensile index 37.86N.m / g, tear index 14.77mN.m 2 / g, burst resistance index 3.93kPa×m 2 / g, the folding endurance is 47 times.

Embodiment 3

[0045] Example 3 (Pulping of Longxugrass)

[0046] Add 300g of Alpine (moisture 10.2%), about 2500ml of the remaining soaking solution in Example 2 (residual alkali content is about 0.6%) to 3000ml 1.0% NaOH solution, soak for 4 hours, and then filter out. Put it into a beaker and place it in a pressure cooker at 0.2MPa and steam at 118°C for 2 hours, then take it out, polish, wash and filter out, and bake it at 105°C to constant weight (about 10 hours) to obtain 143g crude cellulose The cellulose yield is 48%. Crude cellulose beating, papermaking and forming operations, and finally the paper performance is tested. The paper properties are as follows: tensile index 37.66N.m / g, tear index 14.57mN.m 2 / g, burst resistance index 3.73kPa×m 2 / g, 46 times of folding endurance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile index | aaaaa | aaaaa |

| Tear index | aaaaa | aaaaa |

| Tensile index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com