Method for preparing active carbon during alkali recovery of papermaking black liquor

A technology for preparing activated carbon and papermaking black liquor, which is applied in the field of pulp and papermaking to achieve good results, reduce treatment costs and solve disposal problems

Inactive Publication Date: 2012-02-29

QILU UNIV OF TECH

View PDF4 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The invention can solve the disposal problem of papermaking black liquor, and the prepared activated carbon can reduce the treatment cost of papermaking wastewater

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0008] The patent of the present invention belongs to the small-scale experimental invention in the laboratory, and has not passed through the intermediate industrialization test. Therefore, the specific embodiment of the present invention is to carry out intermediate industrialization test, and determine the production line for preparing activated carbon from alkaline chemical pulping black liquor.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

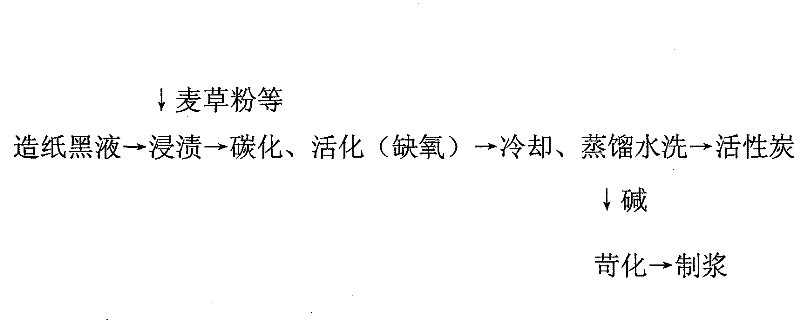

The invention discloses a method for preparing active carbon during the alkali recovery of papermaking black liquor. The method comprises the following steps of: mixing papermaking black liquor with wheat straw powder, cotton straw powder and corn stalk powder, soaking for 10-30 hours, putting into an activating oven, heating to 500-900 DEG C at the heating rate of 5-20 DEG C / min in the anaerobic state for pyrolyzing for 1-4 hours; bleaching an activated product with distilled water, and drying to obtain active carbon; and recovering alkali from the bleaching liquid, and causticizing to obtain alkali for pulping. The methylene blue adsorption value of the prepared active carbon is 4-9 mg / 0.1g, and the active carbon can be used for treating waste water in a papermaking factory and has a good effect; and in the preparing process of the active carbon, no waste water or waste gas is discharged. The problem of treatment of papermaking black liquor can be solved, and the cost for papermaking waste water treatment can be lowered by using the prepared active carbon. The method belongs to the technical fields of pulping and papermaking.

Description

Technical field: [0001] The invention belongs to the technical field of pulping and papermaking Background technique: [0002] Environmental pollution caused by the paper industry has long troubled people. In papermaking wastewater, black liquor is the main source of pollution. The direct discharge of papermaking black liquor into rivers and oceans will cause eutrophication in local waters and destroy the original ecological balance. As a result, it has a notorious reputation for polluting the environment. The so-called papermaking black liquor is the alkaline black liquor left after extracting and separating the cellulose that can be used to make paper in plants. Papermaking black liquor is mainly composed of lignin and hemicellulose. These two components function similarly to cellulose, and together they support the plant's cell walls. However, lignin and hemicellulose are far less long and flexible than cellulose cells and have long been considered papermaking waste....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D21C11/04C01B31/08

Inventor 葛培锦陈嘉川

Owner QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com