Method for recovering pulping black liquor alkali by virtue of sulfate process

A recovery method and black liquor caustic soda technology, applied in the regeneration of lye, lime production and other directions, can solve problems such as the inability to efficiently absorb H, and achieve the effects of increasing the carbon conversion rate, eliminating the danger of explosion when encountering water, and avoiding corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

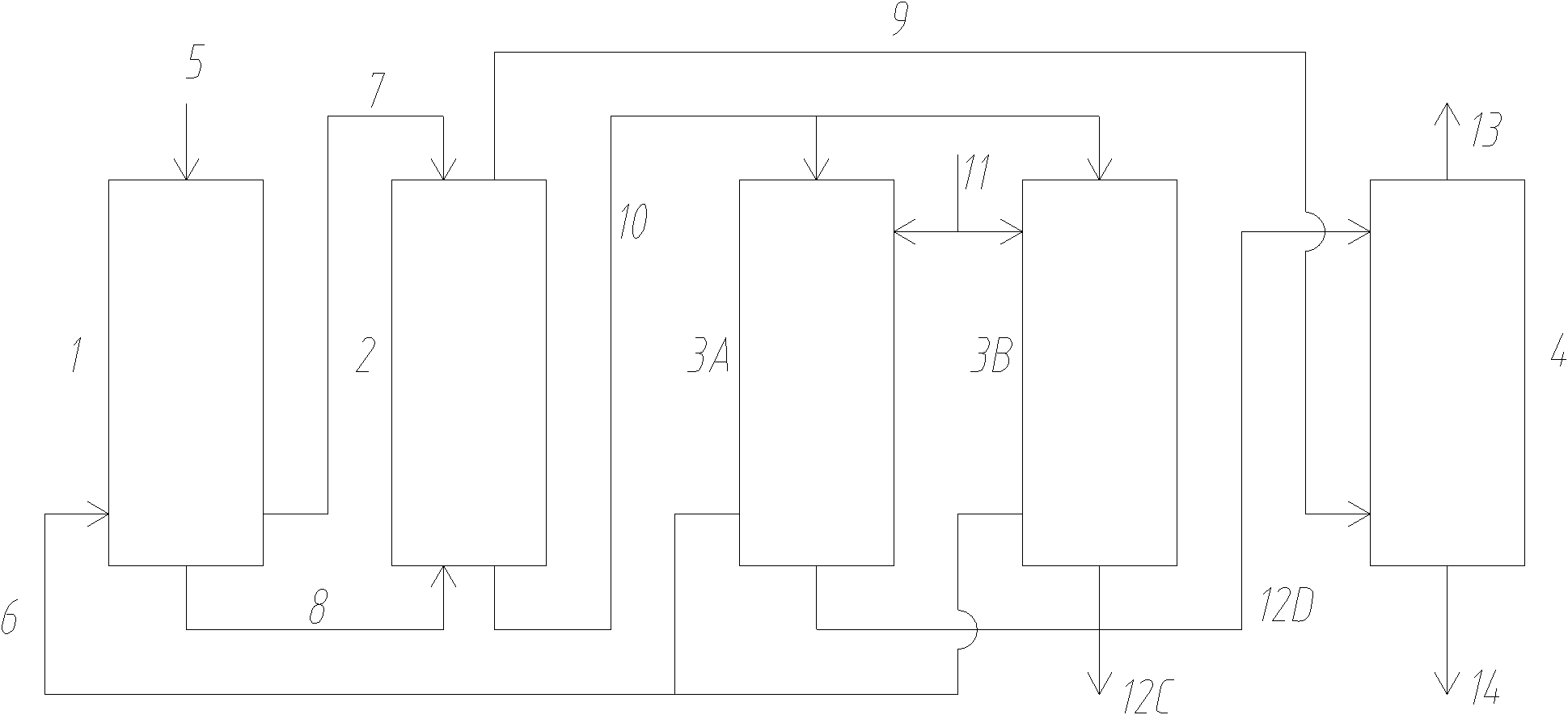

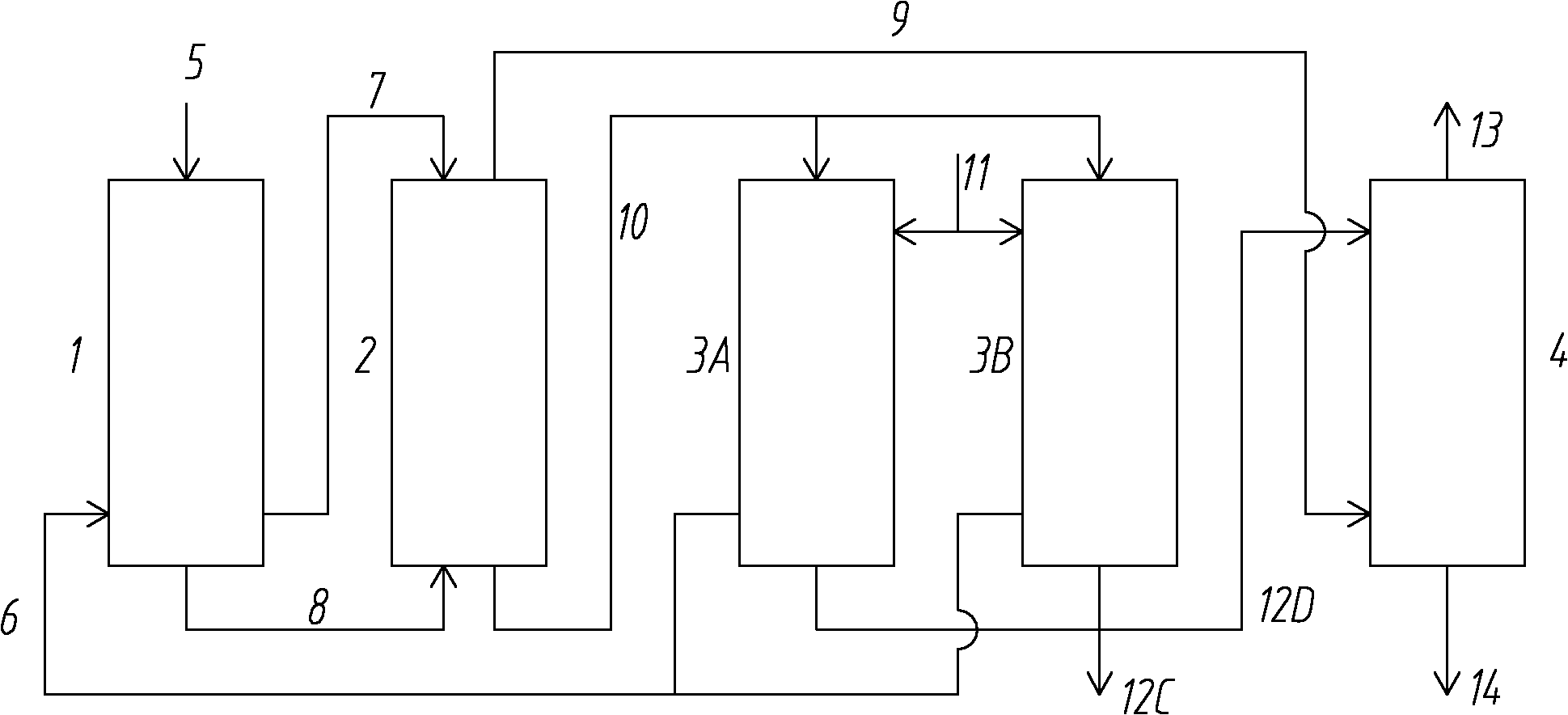

[0032] Such as figure 1 shown. 1 set of 240tds / d (tons of solids per day) gasification alkali recovery system, the solid content of the black liquor treated is 62%, the total sulfur content is 3.17%, the sodium content is 16.9%, and the high calorific value on a dry basis is 13MJ / kg. The liquid power is equivalent to about 36MW; the thick black liquor from pipeline 5 (with Glauber's salt added according to the prior art) has a temperature of 100°C, a flow rate of 16.14t / h, and Na 2 O 3TiO 2 The mass flow rate is 7.93t / h; the average operating temperature of pyrolysis furnace 1 is 850°C, and the air volume of pyrolysis furnace 1 is 9240m 3 / h (normal state), ignoring the temperature drop of the gas discharged from the pyrolysis furnace 1, the volume flow rate of the gas entering the gasification furnace 2 from the pipeline 8 is 47500m 3 / h, mainly water vapor and carbon dioxide, the materials transported into the gasifier by the conveying equipment 7 are black liquor semi-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com