Method for recycling hydrogen sulfide waste gas

A hydrogen sulfide and waste gas technology, applied in chemical instruments and methods, separation methods, pulping waste gas treatment, etc., can solve the problems of insufficient utilization and products that cannot be added again, so as to realize reuse, reduce pressure and solve environmental pollution and production safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

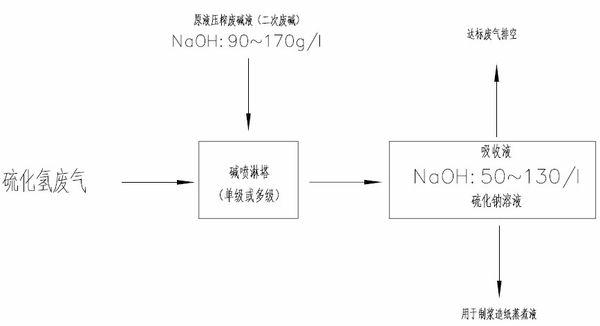

Image

Examples

Embodiment 1

[0031] A method for recycling hydrogen sulfide waste gas, the main steps are as follows:

[0032] A. Pulp is impregnated to obtain alkali fiber. The pulp here mainly refers to cotton, wood or wood II pulp. The waste lye produced after the alkali fiber is squeezed through the pressing process, and the waste lye is treated by membrane filtration to recover 50% of the hydroxide After sodium, obtain secondary waste lye, sodium hydroxide content is 170g / L in the secondary waste lye, and the alkali fiber content of hemicellulose is 30g / L;

[0033] The membrane filtration treatment refers to passing the spent alkali through a nanofiltration membrane with a pore size of 10nm. Sodium hydroxide can pass through the membrane pores, but the alkali fiber of hemicellulose cannot pass through. Therefore, a part of sodium hydroxide can be separated and recovered for production, and the secondary The alkali concentration of spent alkali is lower than that of primary spent alkali;

[0034] B. ...

Embodiment 2

[0048] A method for recycling hydrogen sulfide waste gas, the main steps are as follows:

[0049] A. Pulp is impregnated to obtain alkali fiber. The pulp here mainly refers to cotton, wood or wood II pulp. The waste lye produced after the alkali fiber is squeezed through the pressing process, and the waste lye is treated by membrane filtration to recover 50% of the hydroxide After sodium, obtain secondary waste lye, sodium hydroxide content is 90g / L in the secondary waste lye, and the alkali fiber content of hemicellulose is 50g / L;

[0050] The membrane filtration treatment refers to passing the spent alkali through a nanofiltration membrane with a pore size of 10nm. Sodium hydroxide can pass through the membrane pores, but the alkali fiber of hemicellulose cannot pass through. Therefore, a part of sodium hydroxide can be separated and recovered for production, and the secondary The alkali concentration of spent alkali is lower than that of primary spent alkali;

[0051] B. T...

Embodiment 3

[0064] A method for recycling hydrogen sulfide waste gas, the main steps are as follows:

[0065] A. Pulp is impregnated to obtain alkali fiber. The pulp here mainly refers to cotton, wood or wood II pulp. The waste lye produced after the alkali fiber is squeezed through the pressing process, and the waste lye is treated by membrane filtration to recover 50% of the hydroxide After sodium, obtain secondary waste lye, sodium hydroxide content is 120g / L in the secondary waste lye, and the alkali fiber content of hemicellulose is 40g / L;

[0066] The membrane filtration treatment refers to passing the spent alkali through a nanofiltration membrane with a pore size of 10nm. Sodium hydroxide can pass through the membrane pores, but the alkali fiber of hemicellulose cannot pass through. Therefore, a part of sodium hydroxide can be separated and recovered for production, and the secondary The alkali concentration of spent alkali is lower than that of primary spent alkali;

[0067] B. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com