Fractional separation method of kraft lignin

A kraft lignin and fractionation separation technology, applied in the field of lignin separation, can solve the problem of complex and uneven structure, achieve the effects of less equipment and investment, simple operation, and low overall production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 800g of absolutely dry poplar wood is packed into a 10L vertical electric heating cooking pot, and the amount of alkali used is 24% (based on Na 2 O meter), the degree of sulfide is 25%, the solid-liquid ratio is 1:5, the temperature is raised to 165°C, the heating time is 1h, and the heat preservation time is 2-3h. After the reaction is over, use the pressure in the pot to collect the discharged black liquor, and then filter it with a Buchner funnel to remove large particles in the black liquor.

Embodiment 2

[0024] (1) Take 100ml of the filtered black liquor in Example 1, add 400ml of distilled water, add 0.7g of DTPA chelating agent for chelating treatment, stir at 25°C for 1.5h, and the stirring speed is 400rpm.

[0025] (2) Add sulfuric acid with a concentration of 2mol / L to the stirred black liquor, slowly adjust the pH value of the solution to 6, continue to stir for 1-2h, and then centrifuge to obtain the lignin component L1, and collect the centrifuged liquid .

[0026] (3) Continue to add sulfuric acid with a concentration of 2 mol / L to the liquid collected in step (2), slowly adjust the pH value of the solution to 4, and keep stirring for 1-2h, and then centrifuge to obtain the lignin component L2, Collect the centrifuged liquid.

[0027] (4) Continue to add sulfuric acid with a concentration of 2 mol / L to the liquid collected in step (3), slowly adjust the pH value of the solution to 2, and keep stirring for 1-2 hours, and then centrifuge to obtain the lignin component ...

Embodiment 3

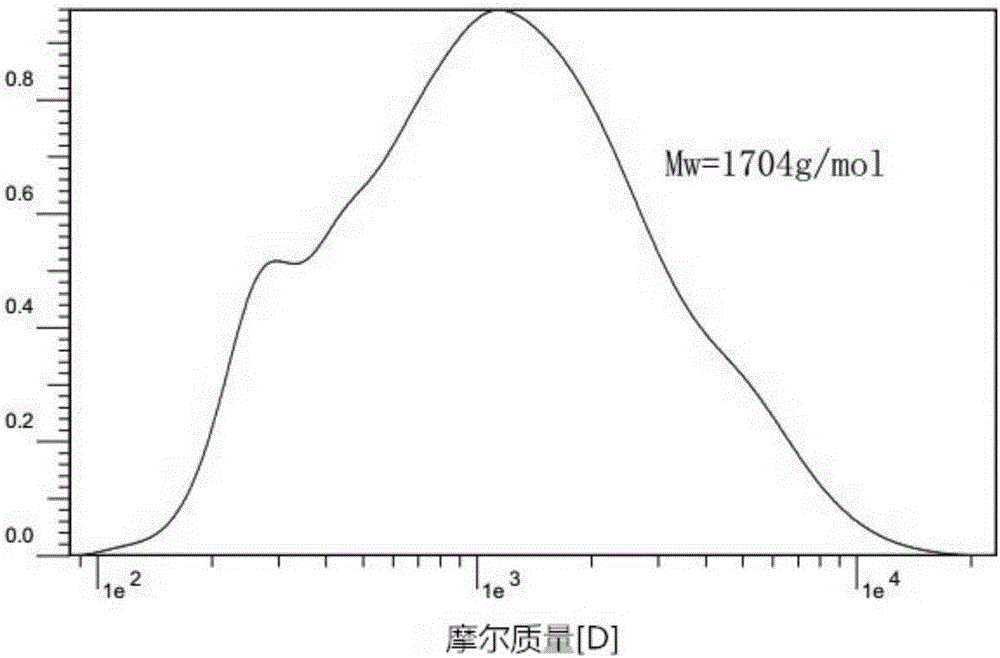

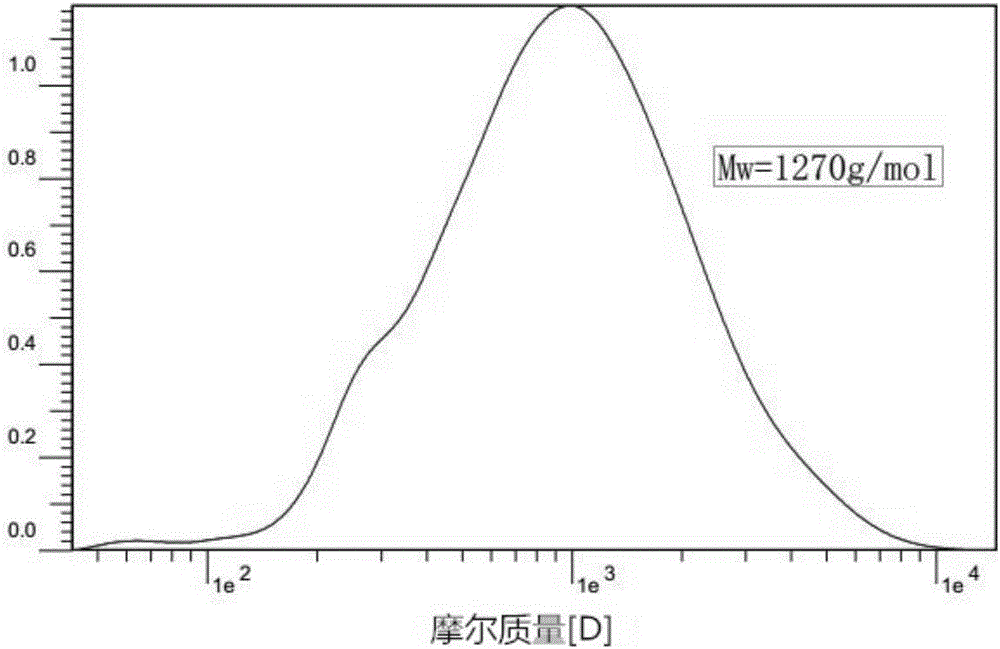

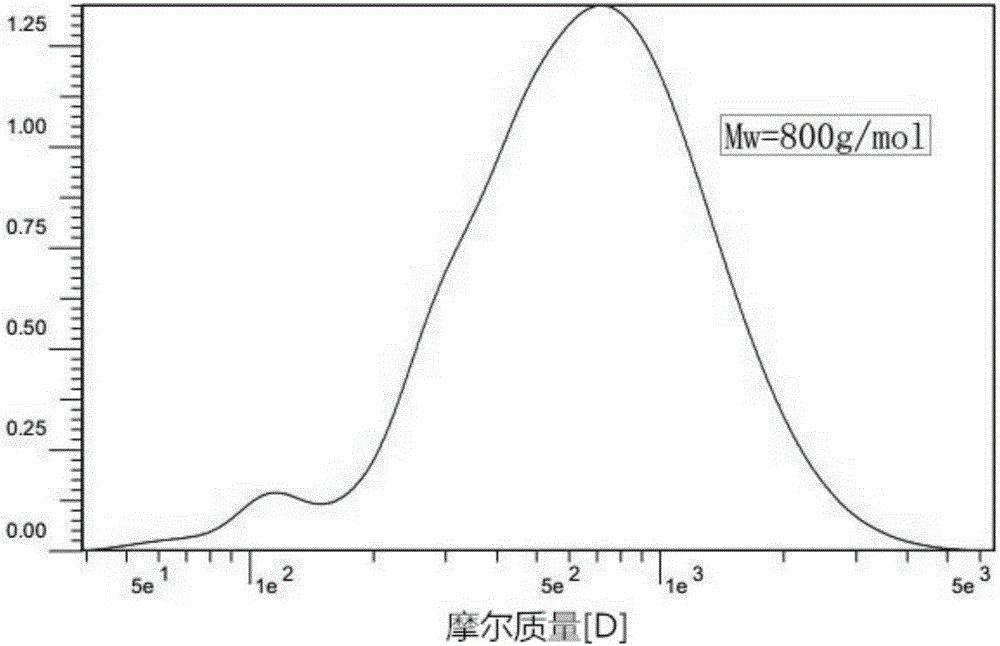

[0030] The determination of lignin molecular weight is as follows: Weigh 4mg acetylated lignin sample and dissolve it in 2ml chromatographic grade tetrahydrofuran, dissolve and filter into PLgel Mixed-D (300×7.5mm, Agilent, USA) chromatographic column for analysis, and inject The amount is 10ul. The eluent was chromatographic grade tetrahydrofuran, and the flow rate was 1ml / min.

[0031] The gel permeation chromatograms of lignin components L1, L2 and L3 are shown in figure 1 , figure 2 and image 3 , the results show that the fractionation of kraft lignin can be realized by this method, and the average weight-average molecular weights of the three separated lignins L1, L2 and L3 are 1704g / mol, 1270g / mol and 800g / mol, respectively.

[0032] It can be seen from the above examples that the acid stepwise precipitation method can obtain lignin with different molecular weight distribution ranges, and the operation process is simple, the required equipment and investment are les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com