Method for producing bleached pulp for viscose fibers from bamboo

A viscose fiber and bamboo technology, which is applied in pulp beating/refining method, pulp bleaching, fiber raw materials, etc., can solve the problems such as failure to achieve expected results, short supply of long fiber resources, and increased cost of chemical fiber pulp, etc. Flexible and versatile production, simple and applicable bleaching process, reduced water and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

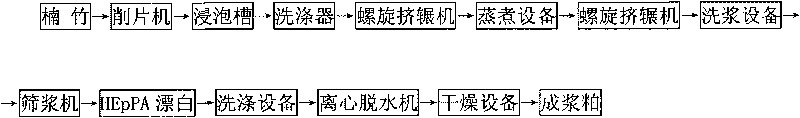

Embodiment 1

[0032] The raw material used in this embodiment is the bamboo wood. Raw materials are cut by a bamboo cutter, with a size of 2-4cm; qualified raw materials are soaked at normal pressure at 95°C for 180 minutes; cooking conditions: total alkali 22%, sulfide degree 25%, AQ0.05%, temperature 170°C, time 120min. After cooking into pulp, wash and sieve. The good pulp is concentrated and bleached. The bleaching process is HEpPA four-stage bleaching. The conditions of the H stage are: 4% hypochlorite (calculated as available chlorine), the temperature is 45°C, the concentration is 10%, and the time is 90min; the conditions of the Ep stage are: sodium hydroxide 2% (Na 2 O meter), hydrogen peroxide 1%, temperature 85 ℃, concentration 15%, time 60min; P section condition is: hydrogen peroxide 2%, sodium hydroxide 1% (NaOH 2 O gauge), temperature 85°C, concentration 20%, time 60min; Section A: hydrochloric acid 2%, time 60min, temperature 30°C, concentration 5%. The whiteness of the o...

Embodiment 2

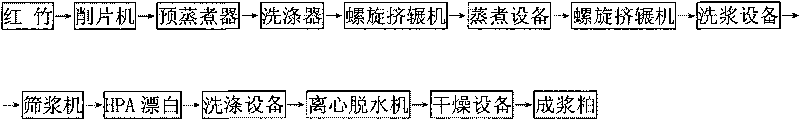

[0034] The present embodiment adopts red bamboo as a raw material, and the raw material is chipped by a bamboo cutting machine with a size of 2 to 4 cm. Qualified raw materials are pre-hydrolyzed, the liquid ratio is 1:6, the temperature is 170°C, and the time is 90 minutes. The cooking conditions are: temperature 170°C, time 120min, total alkali 17.5%, degree of sulfide 25%, green oxygen 0.05%. The good pulp bleaching process is HPA, the conditions of the H section are: hypochlorite 5% (calculated as available chlorine), the temperature is 45°C, the concentration is 10%, and the time is 90min; the conditions of the P section are: hydrogen peroxide 3%, sodium hydroxide 1.5 % (Na 2 O meter), temperature 85°C, concentration 20%, time 60min; Section A: hydrochloric acid 3%, time 60min, temperature 30°C, concentration 5%. The whiteness of the obtained pulp is ≥83% ISO, the content of Type A cellulose is ≥91%, the ash content is ≤0.15%, and the dynamic viscosity is 8.6mPa.S, meet...

Embodiment 3

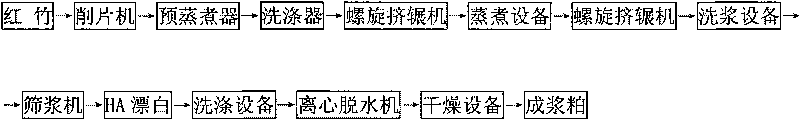

[0036] The present embodiment adopts red bamboo as raw material, and wherein except pulp bleaching, other steps are the same as embodiment 2. The good pulp bleaching process is HA, and the conditions of the H section are: hypochlorite 6% (calculated as available chlorine), temperature 45°C, concentration 10%, time 150min; A section: hydrochloric acid 2%, time 60min, temperature 30°C, concentration 5%. The whiteness of the obtained pulp is ≥77% ISO, the content of cellulose A is ≥92%, the ash content is ≤0.18%, and the dynamic viscosity is 9.7mPa.S, meeting the requirements of bamboo pulp products for viscose staple fiber in the national textile industry standard.

[0037] From Example 1, Example 2 and Example 3, it can be seen that the performance of the pulp is superior, and can meet the requirements of the bamboo pulp product for viscose staple fiber in the national textile industry standard; Methods The bamboo pulp pulping process saves energy consumption, makes full use o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com