Emulsified bitumen and preparation method thereof

A technology for emulsified asphalt and emulsifier, which is used in building components, building insulation materials, buildings, etc., can solve the problem of high cost of emulsifier, and achieve the effects of low cost, good emulsification effect and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

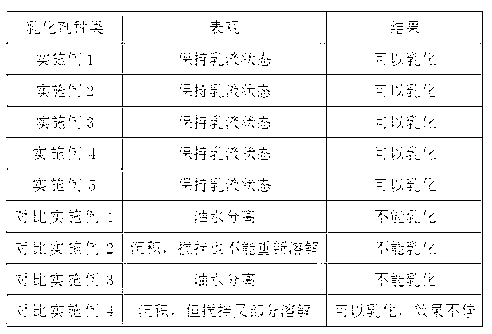

Examples

Embodiment 1

[0025] Example 1. Preparation of lignin cyanamide and amine derivative emulsified pitch from high boiling alcohol lignin

[0026] Weigh 15g of high-boiling alcohol lignin and 2g of melamine into a three-necked flask with stirring, add 90ml of 1% sodium hydroxide solution to dissolve it, add 15ml of formaldehyde with a content of 37%, and heat up to 80°C, stir , react for 1.0 h; then use 2.5mol / L NaOH solution to adjust the pH to about 10, add 20g of diethylenetriamine, maintain 80°C, constant temperature, slowly add 20ml of formaldehyde solution with a content of 37%, stir and reflux for 2.0 h; after the reaction is completed, pour out while hot to obtain a solution of derivatives of lignin cyanamide and amine. Prepare lignin cyanamide and amine derivative emulsifier solution according to the requirement of concentration of 1.1% by weight, and then adjust the pH of the solution to about 2.0 with concentrated hydrochloric acid. Then put 80ml of the prepared emulsifier soluti...

Embodiment 2

[0027] Example 2. Preparation of lignin cyanamide and amine derivative emulsified asphalt by enzymatic hydrolysis of lignin

[0028]Weigh 20g of enzymatic lignin, 1g of melamine into a three-necked flask with stirring, add 80ml of sodium hydroxide with a percentage concentration of 1% to dissolve it, add 20ml of formaldehyde with a content of 37%, and heat up to 75°C, stir, React for 1.5 h; then use 2.5 mol / L NaOH solution to adjust the pH to about 10, add 30 g of diethylene triamine, maintain 75 ° C, constant temperature, slowly add 20 ml of 37% formaldehyde solution dropwise, stir and reflux for 1.5 h; after the reaction is completed, pour out while hot to obtain a solution of derivatives of lignin cyanamide and amine. Prepare lignin cyanamide and amine derivative emulsifier solution according to the requirement of concentration of 1.2% by weight, and then adjust the pH of the solution to about 2.5 with concentrated hydrochloric acid. Then put 80ml of the prepared emulsi...

Embodiment 3

[0029] Example 3. Preparation of lignin cyanamide and amine derivative emulsified pitch from high boiling alcohol lignin

[0030] Weigh 15g of high-boiling alcohol lignin, add 3g of dicyandiamide to a stirred three-necked flask, add 20 ml of ammonia with a percentage concentration of 25% to dissolve it, add 15 ml of formaldehyde with a content of 37% and 20 ml of deionized water, Raise the temperature to 80°C, stir, and react for 1.0 h; then adjust the pH to about 10 with 2.5mol / L NaOH solution, add 20g of trienetetramine, maintain 80°C, keep the temperature constant, and slowly add 25 ml of 37% The formaldehyde solution was stirred and refluxed for 2.5 hours; after the reaction was completed, it was poured out while hot to obtain a solution of lignin cyanamide and amine derivatives. 0。 According to the requirements of the weight percent concentration of 1.1% deployment lignin cyanamide and amine derivative emulsifier solution, and then adjust the pH of the solution to 3.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com