Chlorinated high polymer with good heat stability and preparation method thereof

A technology of thermal stability and high polymer, applied in the field of chlorinated high polymer and its preparation, can solve the problems of heat resistance and poor light aging performance, and achieve the effects of low manufacturing cost, environmental protection and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

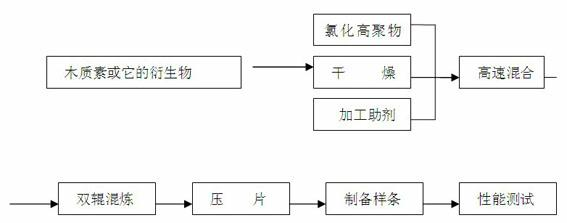

[0023] The preparation process of chlorinated high polymer materials with good thermal stability: PVC or chlorinated polyethylene powder is pre-dried at 100°C for 20-24 hours, first 100 parts of PVC or chlorinated polyethylene powder, 5-25 parts of solvent-based Lignin and appropriate amount of other processing aids are weighed according to the formula, put into a high-speed mixer and pre-mixed at high speed for 5-10 minutes, then add a certain amount of plasticizer and mix again at high speed. After mixing, the mixed material is placed on a double-roller mill for mixing, and the temperature of the double-rollers of the mill is 140-150°C. After mixing evenly, take out the tablet. The sheet is cut into the size of the inner cavity of a standard tableting mold, and the mold is preheated on a flat vulcanizing machine at a temperature of 150-160°C for 5-15 minutes. Then put the sheet into the mold and preheat for 5-15 minutes. Then pressurize to 12-15MPa, keep the pressure for 1...

Embodiment 1

[0028] Example 1. Adding high-boiling alcohol lignin as heat-stabilizing modifier for PVC

[0029] PVC powder was pre-dried at 100°C for 24h, weighed 200g of PVC powder, 20g of high boiling alcohol lignin dried at 80°C for 24h, 4g of calcium-zinc stabilizer, 40g of dibutyl phthalate Put the plasticizer into the high-speed mixer and pre-mix at high speed for 8 minutes. After mixing, put the mixed material on the double-roll mill for mixing. The temperature of the double-roll of the mill is 140°C. After mixing evenly, take out the tablet. The sheet was cut into the size of the inner cavity of a standard sheeting mold, and the mold was preheated on a flat vulcanizing machine at a temperature of 160°C for 5 minutes. Then put the sheet into the mold and preheat for 5min. Then pressurize to 15MPa, keep the pressure for 2 minutes, and deflate, repeat this three times; finally keep the pressure for 3 minutes, take out the mold and carry out cold pressing for 10 minutes. Finally,...

Embodiment 2

[0030] Example 2. Adding enzymatic lignin as thermal stability modifier for polyvinyl chloride

[0031] PVC powder is pre-dried at 100°C for 24 hours, weighed 200 grams of PVC powder, 30 grams of enzymatic lignin dried at 80°C for 24 hours, 4 grams of calcium-zinc stabilizer, and 40 grams of dibutyl phthalate plasticized Put the agent into the high-speed mixer and pre-mix at high speed for 8 min. After mixing, the mixed material was placed on a double-roll mill for mixing, and the temperature of the double-roll of the mill was 140° C. After mixing evenly, take out the tablet. The sheet was cut into the size of the inner cavity of a standard sheeting mold, and the mold was preheated on a flat vulcanizing machine at a temperature of 160°C for 5 minutes. Then put the sheet into the mold and preheat for 5min. Then pressurize to 15MPa, keep the pressure for 3 minutes, and deflate, repeat this three times; finally keep the pressure for 3 minutes, take out the mold and carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com