Prepn of high-boiling alcohol lignin epoxy resin

A high-boiling alcohol lignin and plain epoxy resin technology, which is applied in the field of epoxy resin manufacturing, can solve the problems of adverse effects on the performance of epoxy resin, changes in the structure of natural lignin, and reduced chemical activity, and achieve good modification effects , increase the softness, the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

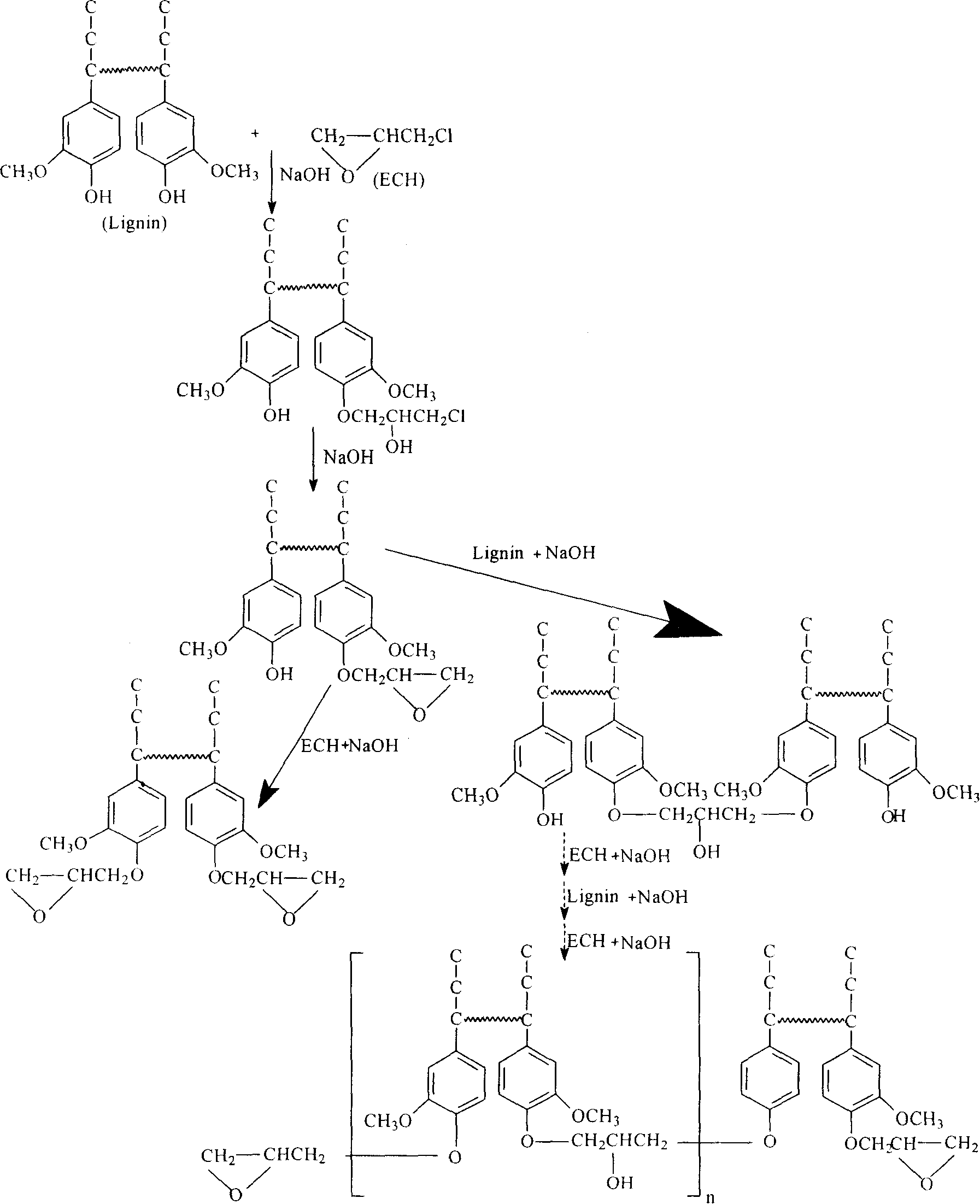

Method used

Image

Examples

Embodiment 1

[0033] 1. Measure 21ml of epichlorohydrin, add it to a clean 250ml three-neck flask (in the container), weigh 5 grams of high-boiling alcohol lignin, pour it into the flask container, heat up to 50°C, stir for 30min, let the high-boiling alcohol Fully dissolve and mix lignin and epichlorohydrin, add 0.8ml of 30% NaOH solution within 20 minutes, raise the temperature to 55-60°C, stir and reflux for 1 hour, raise the temperature to 70°C, and add 2ml of 30% NaOH solution within 20 minutes NaOH solution, stirred and refluxed for 1 hour, evaporated excess epichlorohydrin under reduced pressure to obtain 10ml of epichlorohydrin and a brown solid that was insoluble in water and had certain elasticity, washed and dried to obtain 10.25 grams of high-boiling alcohol wood Plain epoxy resin.

[0034] 2. Effects of different additions of epichlorohydrin on the synthesis ratio, yield and epoxy value of lignin-based epoxy resin

[0035] According to the ratio in Table 1-1, first measure epi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com