Enzymatic hydrolysis lignin epoxy resin material formula and its preparation method

A technology of plain epoxy resin and enzymatic lignin, which is applied in the field of comprehensive utilization of biomass resources and epoxy resin manufacturing industry, can solve the problems of high impurity content, adverse effects on the performance of epoxy resin, and high price, and achieve high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

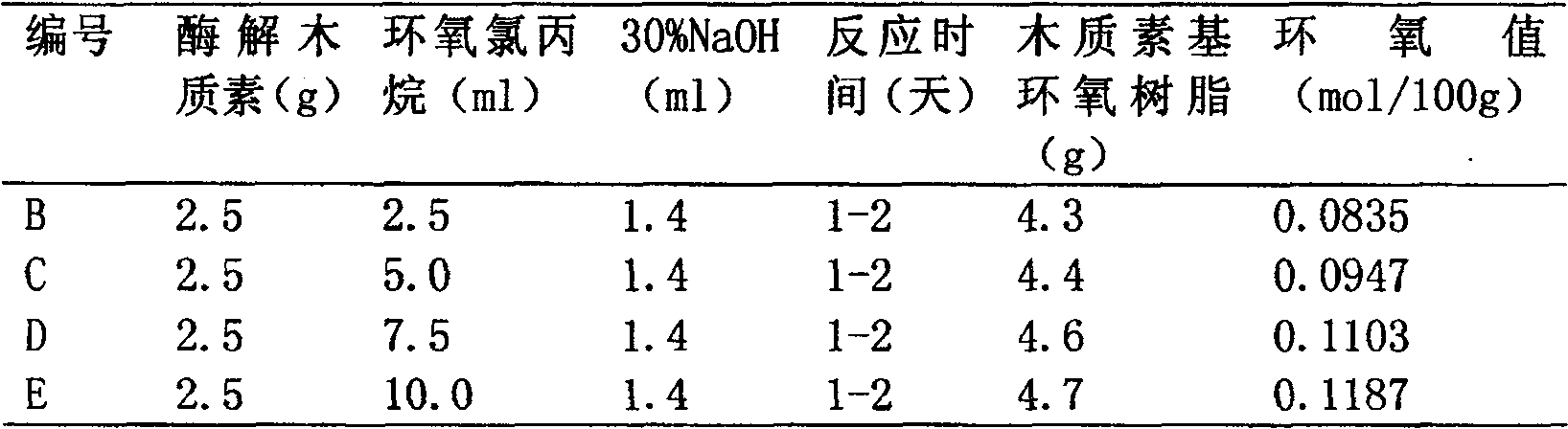

Method used

Image

Examples

Embodiment 1

[0024] Measure 21ml of epichlorohydrin, add it to a clean 250ml three-necked flask, weigh 5g of enzymatically hydrolyzed lignin, pour it into the flask, heat to 50℃, stir for 30min, let the lignin and epichlorohydrin fully dissolve and mix. Add 0.8ml of 30% NaOH solution within 20 minutes, raise the temperature to 55-60°C, stir and reflux for 1 hour, raise the temperature to 70°C, add 2ml of 30% NaOH solution within 20 minutes, then stir and reflux for 1 hour, in the pressure range 5-10mmHg, 1.5-2.0 hours, the excess epichlorohydrin is distilled off under reduced pressure at a temperature of 90℃ to obtain 10ml epichlorohydrin and a brown solid which is insoluble in water and has a certain degree of elasticity, which is obtained by washing and drying 10.85g brittle brown solid enzymatically hydrolyze lignin epoxy resin.

Embodiment 2

[0026] Measure 25ml epichlorohydrin and 15ml ethanol, add to a clean 250ml three-necked flask, weigh 5g enzymatically hydrolyzed lignin, pour it into the flask container, add 0.3g nano silica, heat to 50°C, stir for 30min, Let the lignin and epichlorohydrin fully dissolve and mix, add 2.0ml of 30% NaOH solution within 20 minutes, heat up to 55-60°C, stir and reflux for 1 hour, add 0.4g of ethylenediamine curing agent and heat up to 70°C, Stir and reflux for another 1 hour. Under the conditions of pressure range of 5-10mmHg, time of 1.5-2.0 hours, and temperature of 90℃, excess epichlorohydrin is distilled off under reduced pressure to obtain a brown solid with certain elasticity, which is washed and dried to obtain 10.60 g Nano-silica toughened and modified enzymatically hydrolyzed lignin epoxy resin.

Embodiment 3

[0028] Measure 25ml epichlorohydrin, add it to a clean 250ml three-necked flask, weigh 3g enzymatically hydrolyzed lignin and 2.5g bisphenol A, pour into the flask container, heat to 50℃, stir for 30min, let lignin and epoxy The chloropropane is fully dissolved and mixed. Within 20 minutes, add 0.8ml of 30% NaOH solution, heat up to 55-60°C, stir and reflux for 1 hour, heat up to 70°C, add 2ml of 30% NaOH solution within 20 minutes, then stir to reflux For 1 hour, the excess epichlorohydrin was evaporated under reduced pressure under the conditions of pressure range of 5-10mmHg, time of 1.5-2.0 hours and temperature of 90℃ to obtain 10ml of epichlorohydrin and a solid that is insoluble in water and has certain elasticity. After washing and drying, 11.30g of light brown solid enzymatically hydrolyzed lignin epoxy resin was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com