Formula and preparation method of enzymatic hydrolysis (EH) lignin modified polyalcohol

A technology for enzymatic hydrolysis of lignin and polyol, applied in the field of polymer material preparation, can solve the problems of difficulty in dissolving, affecting the promotion and application of lignin, poor solubility of enzymatic lignin, etc., and achieves low manufacturing cost, high purity, and high retention. effect of chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

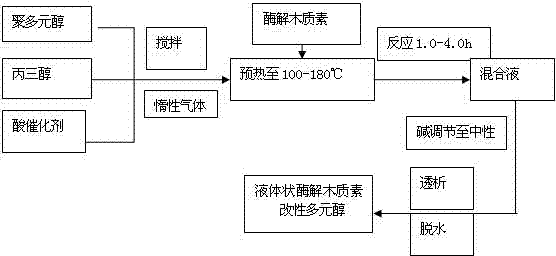

Method used

Image

Examples

Embodiment 1

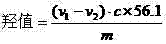

[0057] Example 1: Preparation of modified polyol with polyethylene glycol as the main liquefaction reagent

[0058] .Take 80g polyethylene glycol-400, 25g glycerol, 2.5g concentrated sulfuric acid, mix these three components evenly, put them in a three-necked flask and preheat to 45℃, add 25g enzymatic lignin under stirring, Warm up to 170℃, react for about 1h under the protection of nitrogen, then terminate, adjust to neutral with 5% sodium hydroxide solution, after cooling, the product is passed through a dialysis membrane to remove inorganic salts, that is, dark red liquid-like enzymatic lignin modification Polyol is about 126g. The obtained product has a hydroxyl value of 384mgKOH / g and a viscosity of 2270mPa·s. The product has a high hydroxyl value and is a uniform liquid, which can directly react with cyanate esters to synthesize polyurethane and solve the problem of insoluble and insoluble lignin. , Affecting the preparation of lignin-modified polyurethane.

Embodiment 2

[0059] Example 2: Preparation of modified polyol with polyethylene glycol as the main liquefaction reagent

[0060] Take 80g polyethylene glycol-600, 20g glycerol, 1.2g concentrated sulfuric acid and 1.8g glacial acetic acid, mix these three components uniformly, put them in a three-necked flask and preheat to 45℃, add 20g enzyme under stirring Dissolve lignin, heat up to 130°C, react for about 1h under nitrogen protection, then terminate, adjust to neutral with 5% sodium hydroxide solution, after cooling, the product is passed through a dialysis membrane to remove inorganic salts to obtain dark red liquid enzymatic hydrolysis The lignin modified polyol is about 118g. The obtained product has a hydroxyl value of 322mgKOH / g and a viscosity of 5130mPa·s. The product has a high hydroxyl value and is a uniform liquid, which can directly react with cyanate esters to synthesize polyurethane and solve the problem of insoluble and insoluble lignin. , Affecting the preparation of lignin...

Embodiment 3

[0061] Example 3: Preparation of modified polyol with mixture of polyethylene glycol and polypropylene glycol as main liquefaction reagent

[0062] Take 45g polyethylene glycol-400, 45g polypropylene glycol-400, 6g glycerol, 2.0g glacial acetic acid and 0.5g concentrated nitric acid, mix these five components uniformly, place them in a three-necked flask and preheat to 45℃ Add 15g of enzymatic lignin under stirring, heat up to 150℃, and terminate the reaction under nitrogen protection for 1 hour. Use a 28% ammonia solution to adjust to neutrality. After cooling, the product is passed through a dialysis membrane to remove inorganic salts. 114g of red liquid enzymatic hydrolysis of lignin-modified polyol. The obtained product has a hydroxyl value of 227mgKOH / g and a viscosity of 530mPa·s. The product has a high hydroxyl value and is a uniform liquid, which can directly react with cyanate esters to synthesize polyurethane. It solves the problem of insoluble and insoluble lignin. ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com