Lignin modified high molecular compatible additive and preparation method thereof

A technology of lignin and additives, applied in the direction of lignin derivatives, chemical instruments and methods, organic chemistry, etc., can solve the problems of poor performance of composite materials, affecting the composite effect of raw materials with different polarities, etc., to achieve sustainable development , Low manufacturing cost, and the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

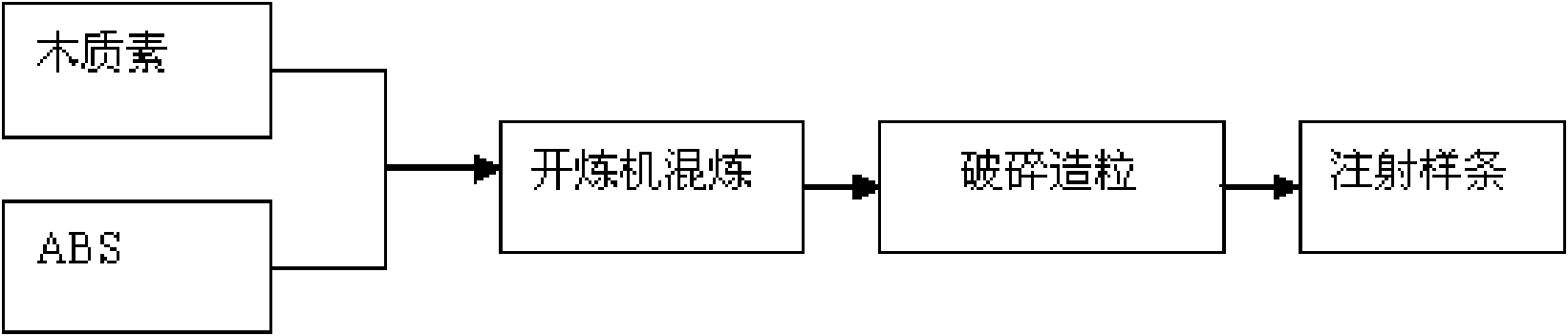

Method used

Image

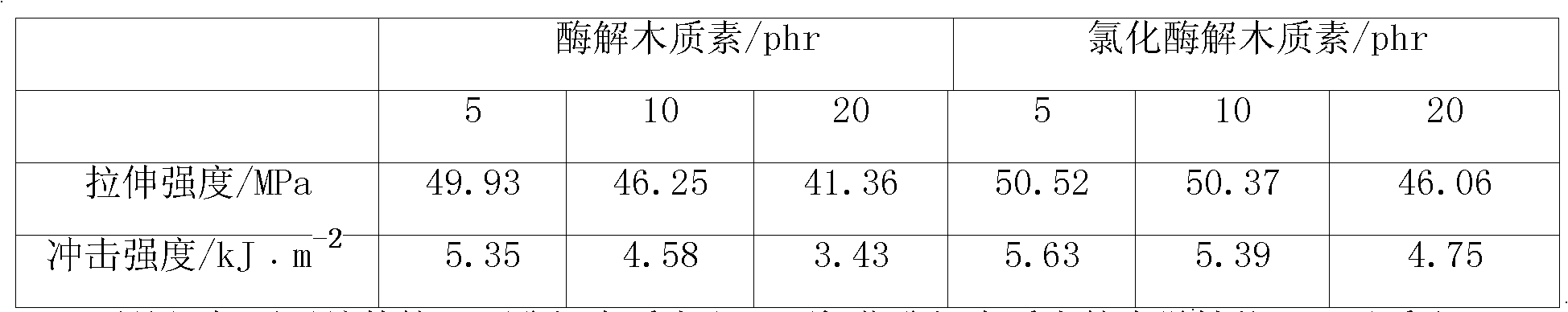

Examples

Embodiment 1

[0043] In a 100-liter reactor, add 50L of deionized water and 1.50Kg of lignin, and after fully stirring at room temperature for half an hour, remove the air, according to the set reaction conditions (temperature 25°C, fully stir for half an hour to remove the air), Pass nitrogen for 3-10 minutes, pass 2.05Kg of chlorine gas to carry out chlorination reaction, react for 2.5 hours, the material obtained by the reaction is washed and filtered, and dried to obtain 0.75Kg of chlorinated lignin (that is, a modified polymer compatible additive) . The chlorine content of the tested product was 29.8%.

Embodiment 2

[0045] In a 100-liter reactor, add 50L of deionized water and 2.00Kg of lignin, and after fully stirring at room temperature for half an hour, remove the air, according to the set reaction conditions (temperature 25°C, fully stir for half an hour to remove the air), Pass nitrogen for 3-10min, pass into 2.05Kg of chlorine to carry out chlorination reaction, react for 2.5h, the material obtained by the reaction is washed and suction filtered, and dried to obtain 1.75Kg of chlorinated lignin (i.e. modified polymer compatible additive ). The chlorine content of the tested product was 29.8%.

Embodiment 3

[0047]In a 100-liter reactor, add 50L of deionized water and 3.00Kg of lignin, and after fully stirring at room temperature for half an hour, remove the air, according to the set reaction conditions (temperature 25°C, fully stir for half an hour to remove the air), Pass nitrogen for 3-10 minutes, pass 2.90Kg of chlorine gas to carry out chlorination reaction, react for 2.5 hours, the material obtained by the reaction is washed and filtered, and dried to obtain 2.90Kg of chlorinated lignin (that is, a modified polymer compatible additive) . The chlorine content of the tested product was 25.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com