Method for preparing fish skin and scale collagen peptide

A technology of fish scale collagen and fish skin, which is applied in the field of food biology, can solve the problems of low peptide content, low yield, and high cost of enzyme preparations, and achieve the effects of low enzyme preparation costs, reduced production costs, and good adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

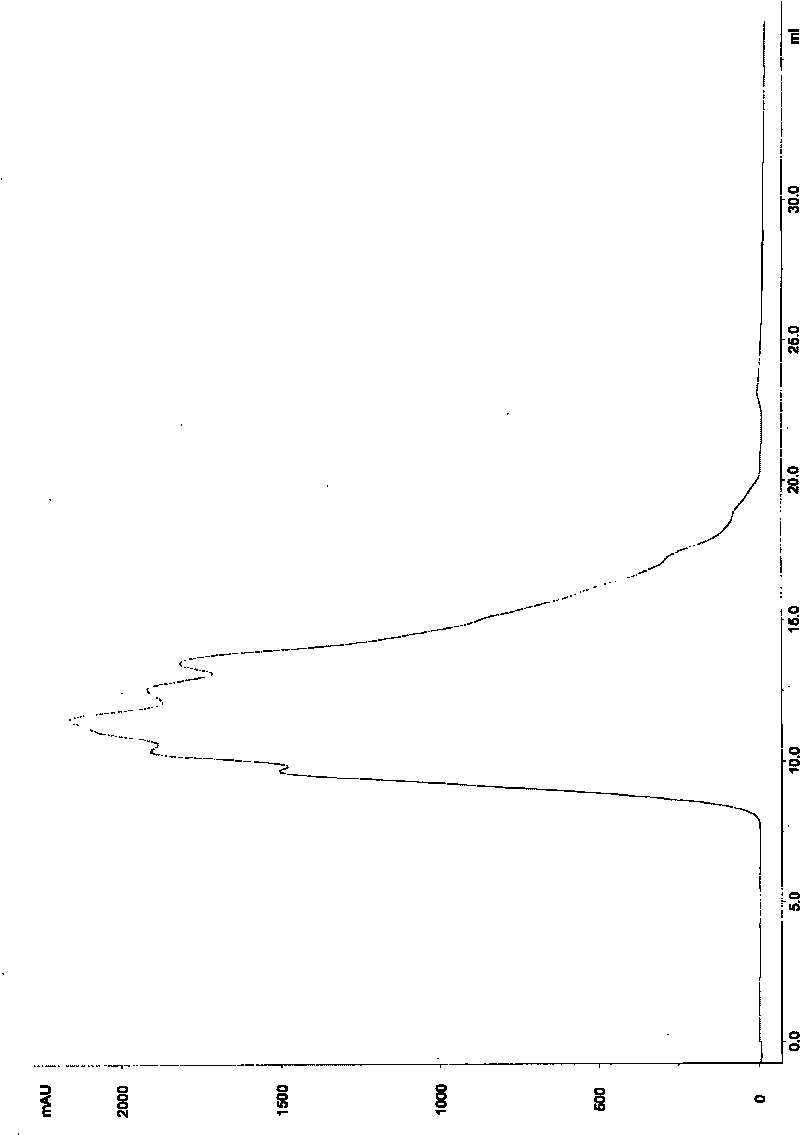

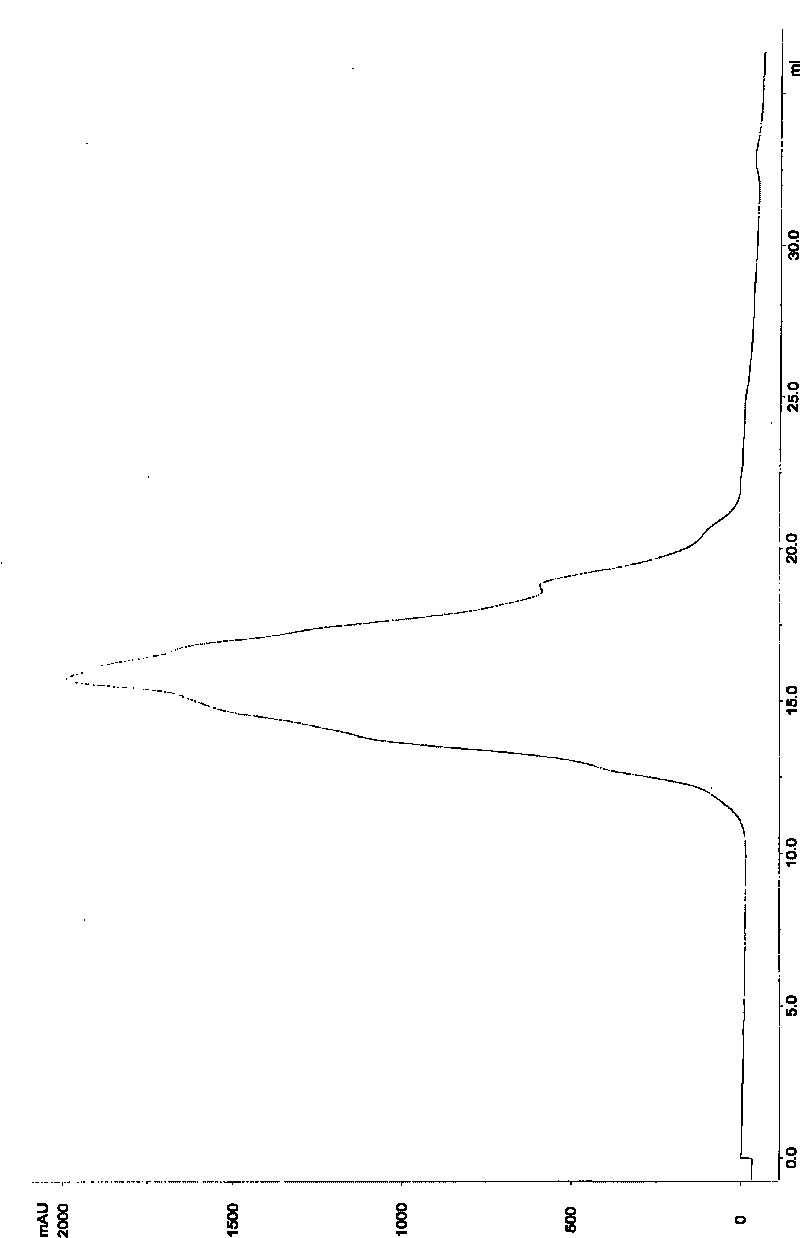

Image

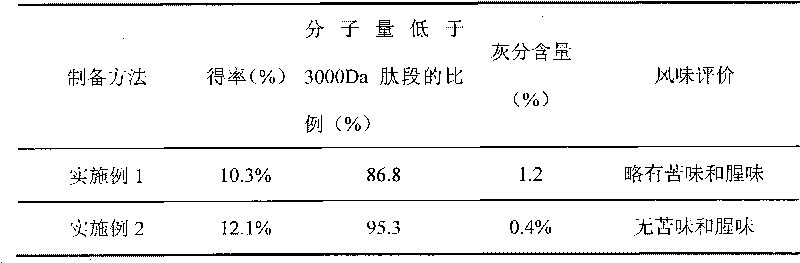

Examples

Embodiment 1

[0021] (1) High-temperature extraction of fish skin and scales; mix tilapia skin and scales 1:1, wash and remove impurities, add 4 times of pure water, extract with hot water at 121°C for 60 minutes, cool to 55°C to obtain fish skin and scales Extraction solution;

[0022] (2) Heat preservation enzymolysis; mix 1% alkaline protease with fish skin and scale extract, and enzymolyze at 55°C for 10 hours;

[0023] (3) Separation; after enzymatic hydrolysis, inactivate the enzyme at 95°C for 30 minutes, cool to 60°C, filter to remove insoluble residues, and obtain crude enzymatic hydrolyzate;

[0024] (4) Eliminate macromolecular proteins: use an ultrafiltration membrane with a molecular weight of 100KDa to perform ultrafiltration on the crude enzymatic hydrolysis solution, and take the permeate to obtain a refined solution;

[0025] (5) Drying: vacuum-concentrate the refined solution until the solid content reaches 30%, and spray-dry to obtain the finished collagen peptide powder...

Embodiment 2

[0027] (1) koji making; with wheat bran as raw material, after the twin-screw extrusion process of screw speed 150r / min, die head temperature 180 ℃, feeding speed 25kg / h, add water to make the moisture content of wheat bran reach 50%, sterilized at 121°C for 10 minutes, inoculated with Aspergillus oryzae, and made koji at 37°C and humidity 95% for 2 days to obtain bran koji;

[0028] (2) High-temperature extraction of fish skin and scales; mix tilapia skin and scales 1:1, wash and remove impurities, add 4 times of pure water, extract with hot water at 121°C for 60 minutes, cool to 55°C to obtain fish skin and scales Extraction solution;

[0029] (3) Insulation enzymolysis; the bran koji with 5% (w / w) weight of the fish skin and scale extract was mixed with the fish skin and scale extract, and enzymatically hydrolyzed at 55° C. for 10 h;

[0030] (4) Separation; after enzymatic hydrolysis, inactivate the enzyme at 95°C for 30 minutes, cool to 60°C, filter to remove insoluble r...

Embodiment 3

[0034] (1) koji making; with wheat bran as raw material, after the twin-screw extrusion process of screw speed 200r / min, die head temperature 150 ℃, feeding speed 20kg / h, add water to make the moisture content of wheat bran reach 45%, sterilized at 111°C for 20 minutes, inoculated with Aspergillus oryzae, koji-making at 25°C and humidity 60% for 3 days to obtain bran koji;

[0035] (2) High-temperature extraction of fish skin and scales; mix tilapia skin and scales 1:1, wash and remove impurities, add 8 times of pure water, extract with hot water at 100°C for 90 minutes, cool to 45°C to obtain fish skin and scales Extraction solution;

[0036] (3) Insulation enzymolysis; mix bran koji with 8% (w / w) weight of fish skin and scale extracts and fish skin and scale extracts, and enzymolyze at 55° C. for 10 h;

[0037] (4) Separation; after enzymatic hydrolysis, inactivate the enzyme at 85°C for 30 minutes, cool to 50°C, filter to remove insoluble residues, and obtain crude enzymat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com