Bacterial strain for producing low temperature alkaline protease

A protease and bacterial strain technology, applied in the direction of bacteria, hydrolytic enzymes, and microbial-based methods, can solve the problems of low catalytic efficiency and no low-temperature basic protein production, and achieve the effect of excellent properties and high protease activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Screening and identification of bacterial strains

[0029] Separation of endophytic bacteria from wakame seaweed collected in Qingdao sea area, and plant the obtained single bacterial colony on the casein medium, observe the situation of each strain producing hyaline circles, and carry out preliminary screening of bacteria species; then produce hyaline circles The strain was inoculated on the liquid fermentation medium, cultured in a shake flask at 25°C for 3 days, centrifuged at 10,000 r / min at 4°C for 15 minutes, and the supernatant was taken to measure its protease activity, and the strain with the highest protease activity was screened out.

[0030] According to "Berger's Bacterial Identification Handbook" and "Systematic Identification", the WFWBac-1 strain was classified and identified according to its physiological and biochemical characteristics.

[0031] Physiological and biochemical identification tests were carried out on the WFWBac-1 strain. Th...

Embodiment 2

[0056] The fermentation condition optimization of embodiment 2 bacterial strains

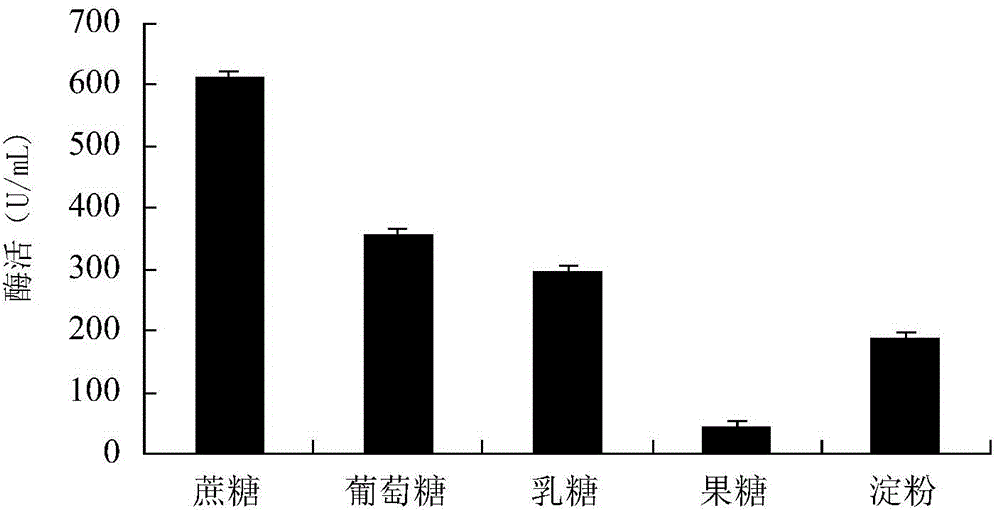

[0057] 1. Effect of carbon source on enzyme production by WFWBac-1 bacteria

[0058] The protease activity was determined after the carbon source to be tested (glucose, sucrose, starch, fructose, lactose) was used as the sole carbon source in the liquid medium, cultured at 25°C and 150r / min for 48h. The result is as figure 1 It was shown that when sucrose was used as carbon source, the enzyme activity of WFWBac-1 strain was the highest, glucose, lactose, starch were lower, and fructose was the lowest. It can be seen that the strain can make full use of the carbon source in sucrose for growth, metabolism and reproduction, so sucrose is the best carbon source for WFWBac-1.

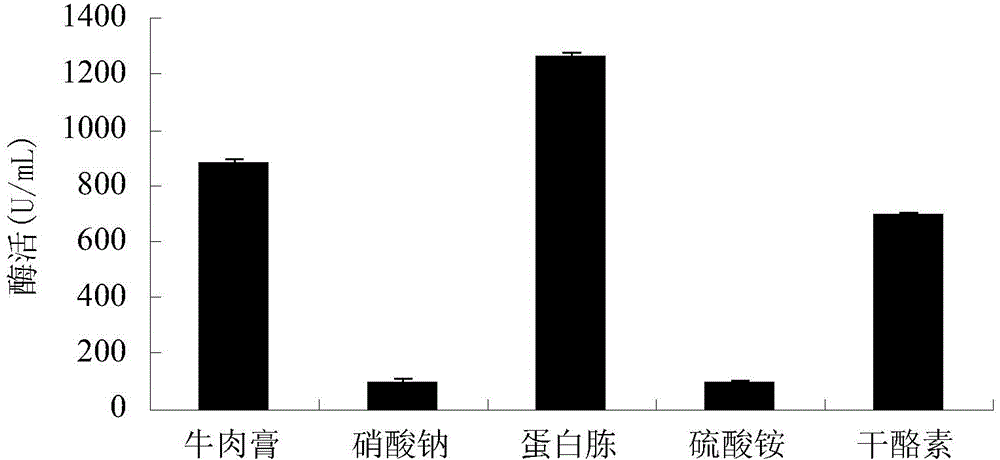

[0059] 2. Effect of nitrogen source on enzyme production by WFWBac-1 bacteria

[0060]In the nitrogen source test, sucrose was used as a fixed carbon source; the nitrogen source to be tested was casein, sodium nitrate, ammo...

Embodiment 3

[0069] The research of the crude enzyme liquid property of embodiment 3 bacterial strains

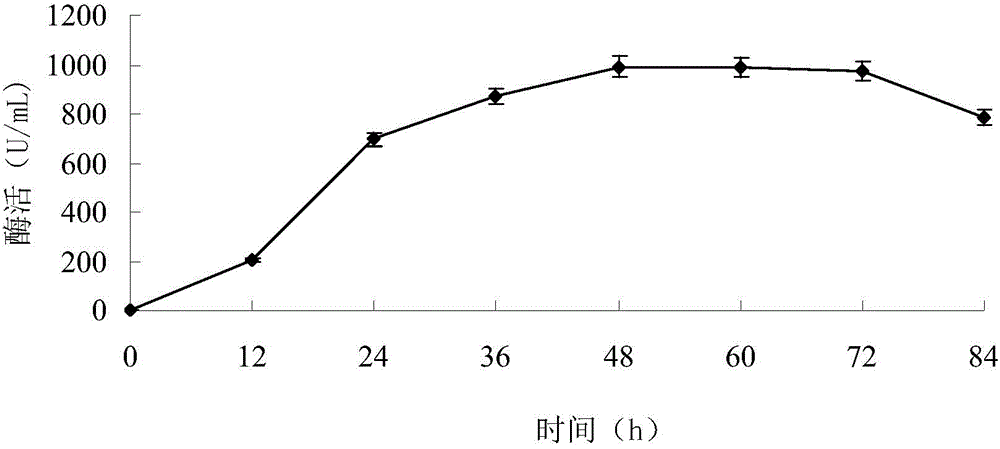

[0070] 1. Determination of the optimum reaction temperature of the enzyme

[0071] Put the crude enzyme solution produced by the fermentation of the screened strain WFWBac-1 at 0, 20, 40, and 80°C respectively for 1 hour, take out the crude enzyme solution, add the substrate azo casein and place it at 37°C , using the Folin-phenol method to measure the enzyme activity and determine the optimum reaction temperature of the enzyme. Such as Figure 7 As shown, the optimum temperature of protease in the crude enzyme solution is 20°C, and the enzyme activity is 1078U / mL at this time, which is the result of the comprehensive action of various proteases, indicating that the protease produced by this bacteria belongs to low-temperature protease.

[0072] 2. Determination of the optimum pH value of the enzyme

[0073] The crude enzyme solution produced by the fermentation of the screened strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com