Method and system for preparing regenerative carbon black by deashing and modifying pyrolytic carbon of waste rubber and plastic products

A technology for plastic products and regenerated carbon black, which is applied in fibrous fillers, dyed low-molecular organic compound treatment, dyed organic silicon compound treatment, etc., can solve the problems of unresolved pyrolysis carbon ash content, poor reaction effect, etc., and achieve Effects of recycling and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

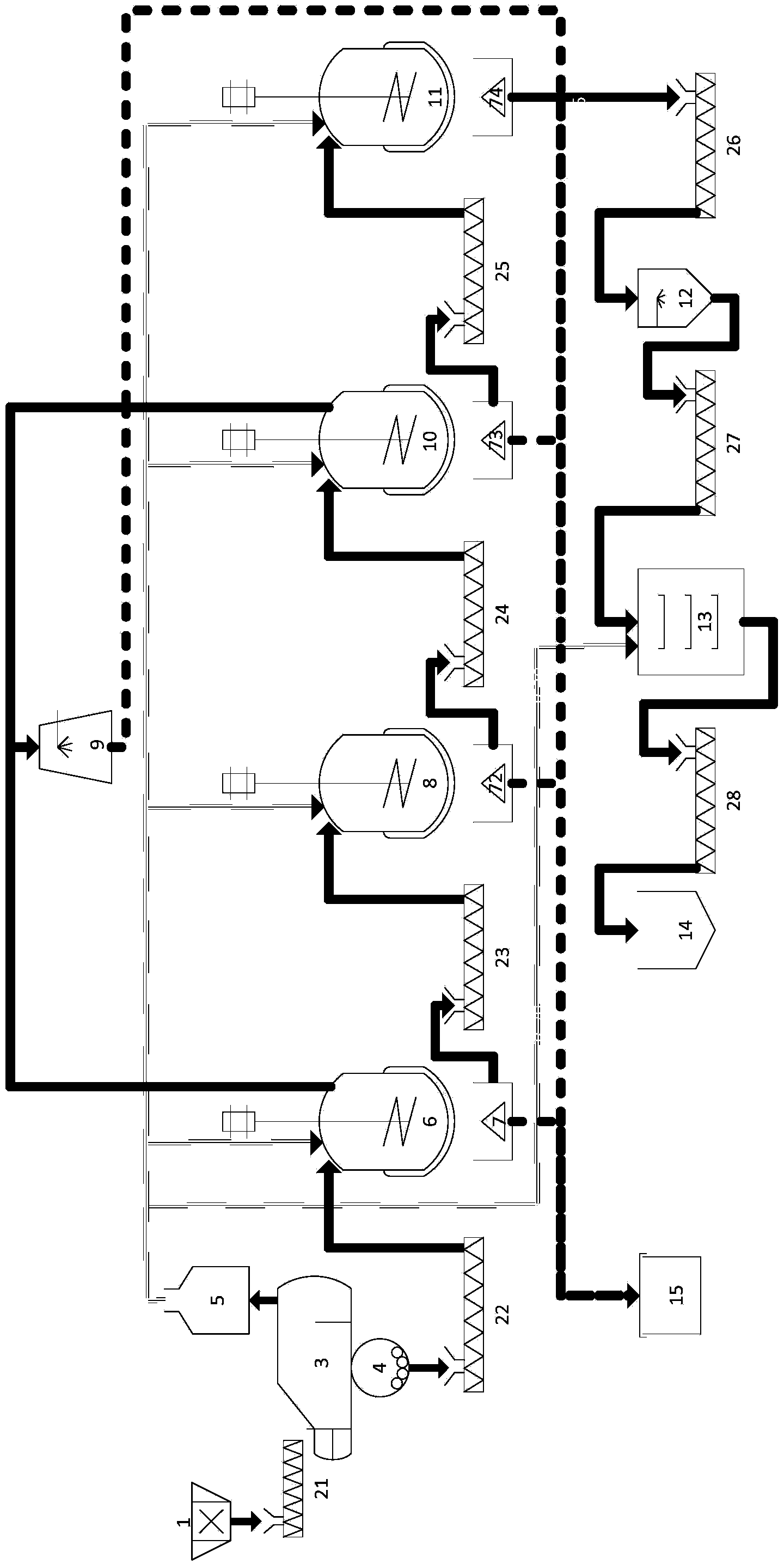

[0033] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

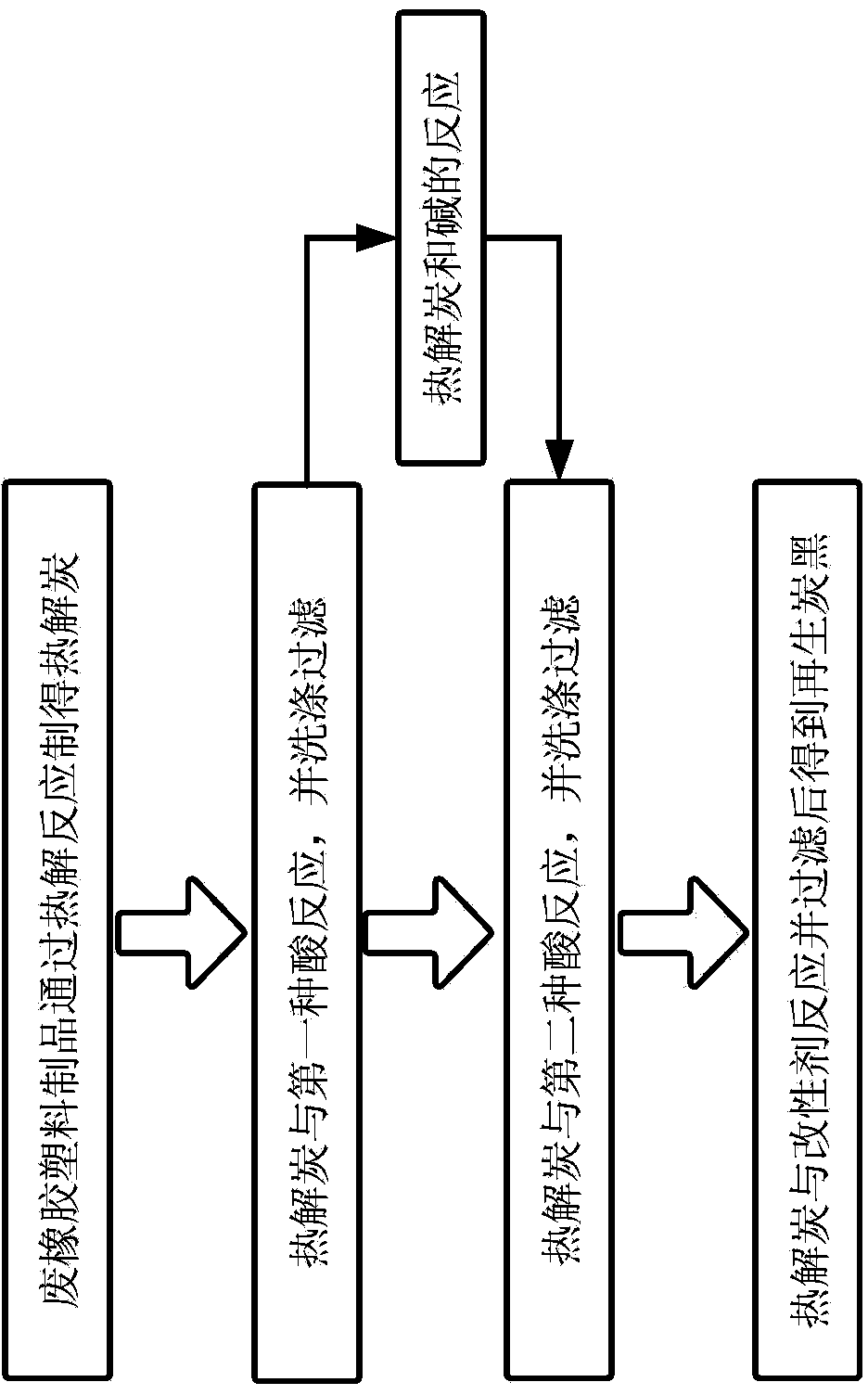

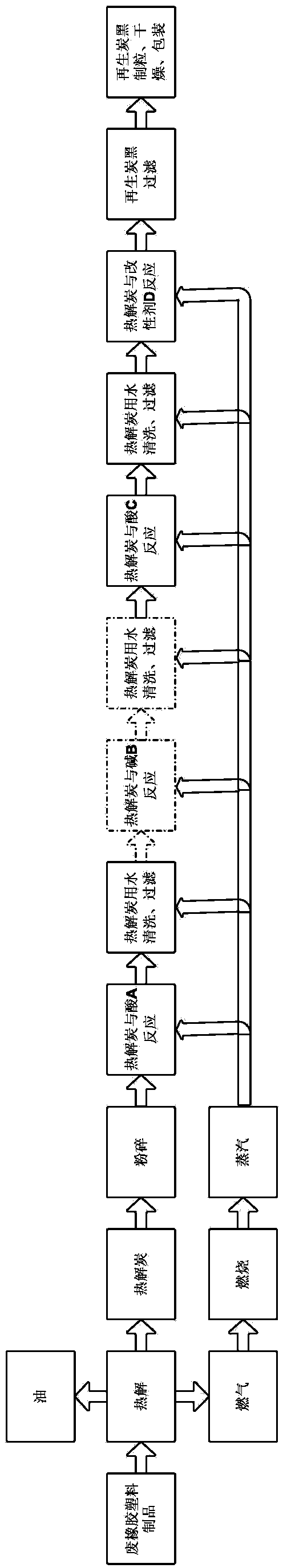

[0034] combine figure 1 , figure 2 As described, the method for producing regenerated carbon black by pyrolysis of waste rubber and plastic products according to the present invention for deashing and modifying comprises the following steps:

[0035] S1, waste rubber and plastic products are produced by pyrolysis process to produce pyrolytic charcoal, oil and combustible gas.

[0036] S2, the pyrolytic carbon is pulverized to a fineness below 325 mesh (particle size <45 μm).

[0037] S3, pyrolytic carbon reacts with acid A to convert part of the ash into soluble salts, which are then removed by washing and filtration.

[0038] Specifically, the reaction process of pyrolytic charcoal and acid A includes: adding acid A to pyrolytic charcoal, stirring and mixing evenly, and heating p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com