A phosphogypsum-based thermal insulation mortar containing expanded perlite

A technology of expanded perlite and thermal insulation mortar is applied in the field of comprehensive utilization of solid waste and building materials, which can solve the problems of poor frost resistance and water resistance, limited bonding ability of substrates and high thermal conductivity, and achieves low production cost, Improved quality and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

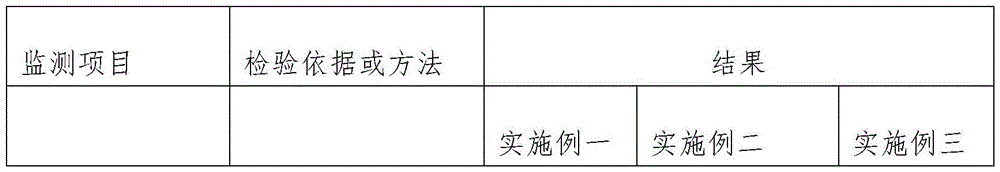

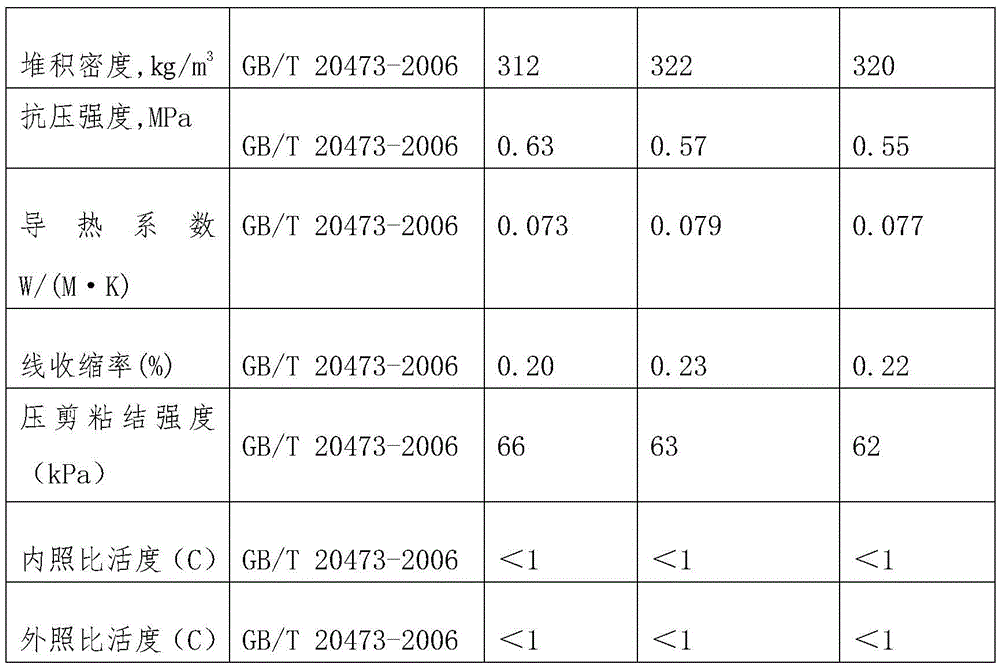

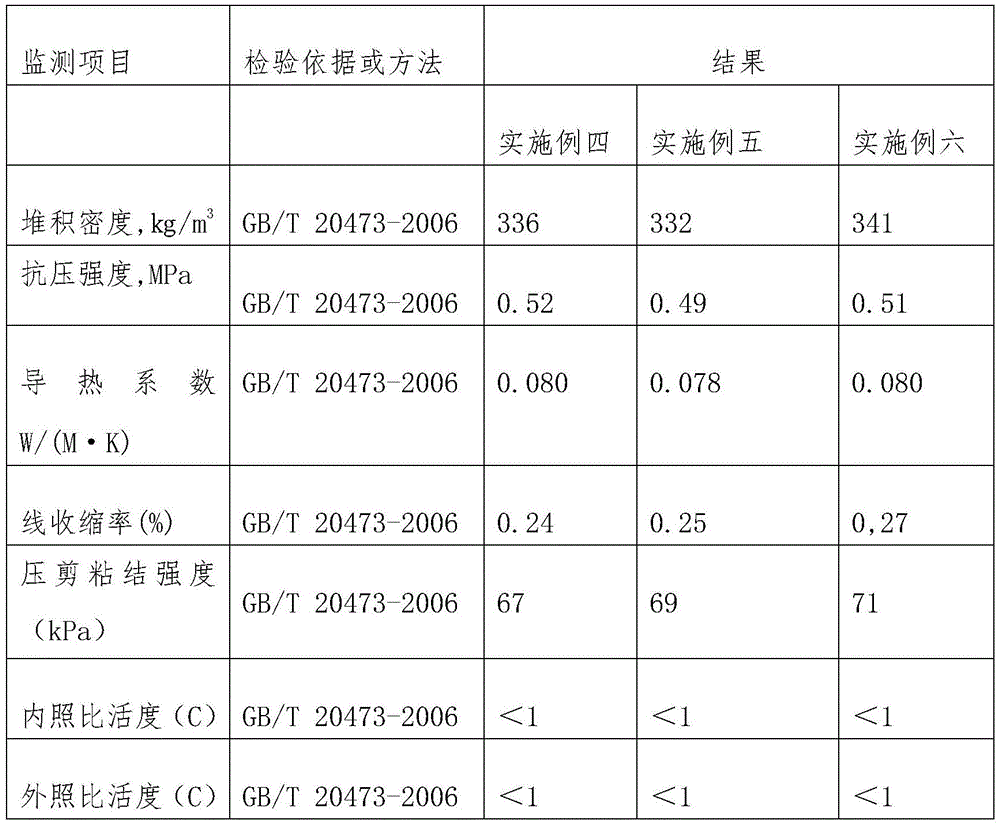

[0024] The raw material composition and parts by weight of the phosphogypsum-based thermal insulation mortar containing expanded perlite are shown in Table 1:

[0025] Table 1

[0026] Raw material serial number raw material name Raw material parts by weight 1 expanded perlite 800 2 plaster of construction 70 3 modifier 14.8 4 retarder 0.1 5 Cellulose Ether Mixture 0.1

[0027] Among them, building gypsum is made by calcination of phosphogypsum produced by wet-process phosphoric acid production. The specific steps are as follows: firstly, phosphogypsum is calcined at 210°C for 2 hours, aged for 5 days to make β hemihydrate gypsum, and the phosphogypsum is processed into Calcined at 355°C for 1 hour to make Type II anhydrous gypsum, then mix β hemihydrate gypsum with anhydrite at a mixing ratio of 3:1.

[0028] The modifier is composite yellow phosphorus slag powder.

[0029] The retarder is a mixture of zinc chloride, sodiu...

Embodiment 2

[0033] The raw material composition and parts by weight of the phosphogypsum-based thermal insulation mortar containing expanded perlite are shown in Table 2:

[0034] Table 2

[0035] Raw material serial number raw material name Raw material parts by weight 1 expanded perlite 1000 2 plaster of construction 74 3 modifier 16.4 4 retarder 0.13 5 Cellulose Ether Mixture 0.15

[0036] Among them, building gypsum is made by calcination of phosphogypsum produced by wet-process phosphoric acid production. Specifically, the phosphogypsum is calcined at 195°C for 2.5 hours, aged for 4 days to make β hemihydrate gypsum, and the phosphogypsum Calcined at 345°C for 2 hours to make type II anhydrite, then mix β hemihydrate gypsum with anhydrite, the mixing ratio is 4:1.

[0037] The modifier is composite yellow phosphorus slag powder.

[0038] The retarder is a mixture of zinc chloride, sodium borate, sodium hexametaphosphate, sodium tr...

Embodiment 3

[0042] The raw material composition and parts by weight of the phosphogypsum-based thermal insulation mortar containing expanded perlite are shown in Table 3:

[0043] table 3

[0044] Raw material serial number raw material name Raw material parts by weight 1 expanded perlite 1200 2 plaster of construction 76 3 modifier 17.6 4 retarder 0.15 5 Cellulose Ether Mixture 0.17

[0045] Among them, building gypsum is made by calcination of phosphogypsum produced by wet-process phosphoric acid production. Specifically, the phosphogypsum is calcined at 198°C for 2.53 hours, aged for 4 days to make β hemihydrate gypsum, and the phosphogypsum Calcined at 348°C for 1.5 hours to make Type II anhydrous gypsum, then mix β hemihydrate gypsum with anhydrite at a mixing ratio of 3.5:1.

[0046] The modifier is composite yellow phosphorus slag powder.

[0047] The retarder is a mixture of zinc chloride, sodium borate, sodium hexametaphosphat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com