Production method for extracting chitosan oligosaccharide from shrimp shells

A production method and chitosan oligosaccharide technology are applied in the field of food processing, which can solve the problems of environmental pollution, waste of resources and the like, and achieve the effects of simple production equipment, low cost, and increased processing added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

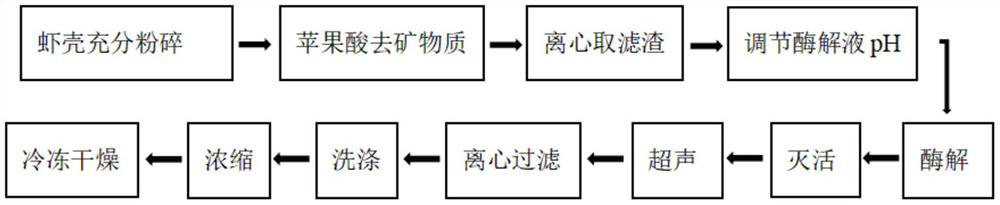

Method used

Image

Examples

Embodiment 1

[0063] A method of producing shell oligosaccharides from a shrimp shell, specific steps:

[0064] (1) Step 1: Dry the shrimp shell at 50 ° C to constant weight, then pulverize the dried shrimp shell, over 80 mesh sieve, to obtain shrimp chopping powder;

[0065] (2) Step 2: Try 1 of the shrimp powder in step 1 to add 1.0 mol / L L-malic acid, which is 1 g: 10 mL, and after 20 min, centrifuge at 4000 rpm 5 min to give the precipitate. Drying to the constant weight to give a shrimp shell powder at a low temperature 50 ° C;

[0066] (3) Step 3: The step 2 is obtained by the decalcinated shrimp chrome; the mass ratio of shrimp chopper powder and water is 1 g: 14ml mixed paste, the pH is 7, and the mass concentration is 3% composite protease (medium) Protease: Alkaline protease is 3: 1), and the enzymatic hydrolysis was found to be found in 65 ° C, then the enzymatic hydrolyzed solution was centrifuged at 4000 rpm for 5 min, and precipitated, and the precipitate dried at a low temperat...

Embodiment 2

[0072] A method of producing shell oligosaccharides from a shrimp shell, specific steps:

[0073] (1) Step 1: Dry the shrimp shell at 50 ° C to constant weight, then pulverize the dried shrimp shell, over 80 mesh sieve, to obtain shrimp chopping powder;

[0074] (2) Step 2: Try 1 of the shrimp powder in step 1 to add 1.0 mol / L L-malic acid, which is 1 g: 10 mL, and after 20 min, centrifuge at 4000 rpm 5 min to give the precipitate. Drying to the constant weight to give a shrimp shell powder at a low temperature 50 ° C;

[0075] (3) Step 3: Section 2 to obtain a shrimp chopper powder; pressing the mass ratio of the shrimp shell and water to 1 g: 18ml mixed paste, adjusting pH 7, adding mass concentration of 4% composite protease (medium Protease: Alkaline protease is 3: 1), and the enzymatic hydrolysis is found to be 3.5 h under 60 ° C, then the enzymatic hydrolyzide is centrifuged at 4000 rpm for 5 min, and the precipitate is taken, and the precipitate is dried at a low temperat...

Embodiment 3

[0081] A method of producing shell oligosaccharides from a shrimp shell, specific steps:

[0082] (1) Step 1: Dry the shrimp shell at 50 ° C to constant weight, then pulverize the dried shrimp shell, over 80 mesh sieve, to obtain shrimp chopping powder;

[0083] (2) Step 2: Try 1 of the shrimp powder in step 1 to add 1.0 mol / L L-malic acid, which is 1 g: 10 mL, and after 20 min, centrifuge at 4000 rpm 5 min to give the precipitate. Drying to the constant weight to give a shrimp shell powder at a low temperature 50 ° C;

[0084] (3) Step 3: Section 2 to obtain a shrimp chopper powder; pressing the mass ratio of the shrimp shell and water to 1 g: 18ml mixed paste, adjusting pH 7, adding mass concentration of 4% composite protease (medium Protease: Alkaline protease is 3: 1), 55 ° C under conditions, and then centrifuge at 4000 rpm under 4000 rpm, and precipitate, dry the precipitate at a low temperature 50 ° C to constant weight Shrimp shell powder obtained by deprotein;

[0085] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com