Pavement brick prepared based on domestic waste incineration fly ash and preparation method thereof

A technology of domestic waste incineration and pavement bricks, which is applied in cement production and other directions to achieve the effect of reducing production costs, reducing solid waste disposal costs, and broadening comprehensive utilization channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method of heavy metal curable pavement brick, which comprises the following steps:

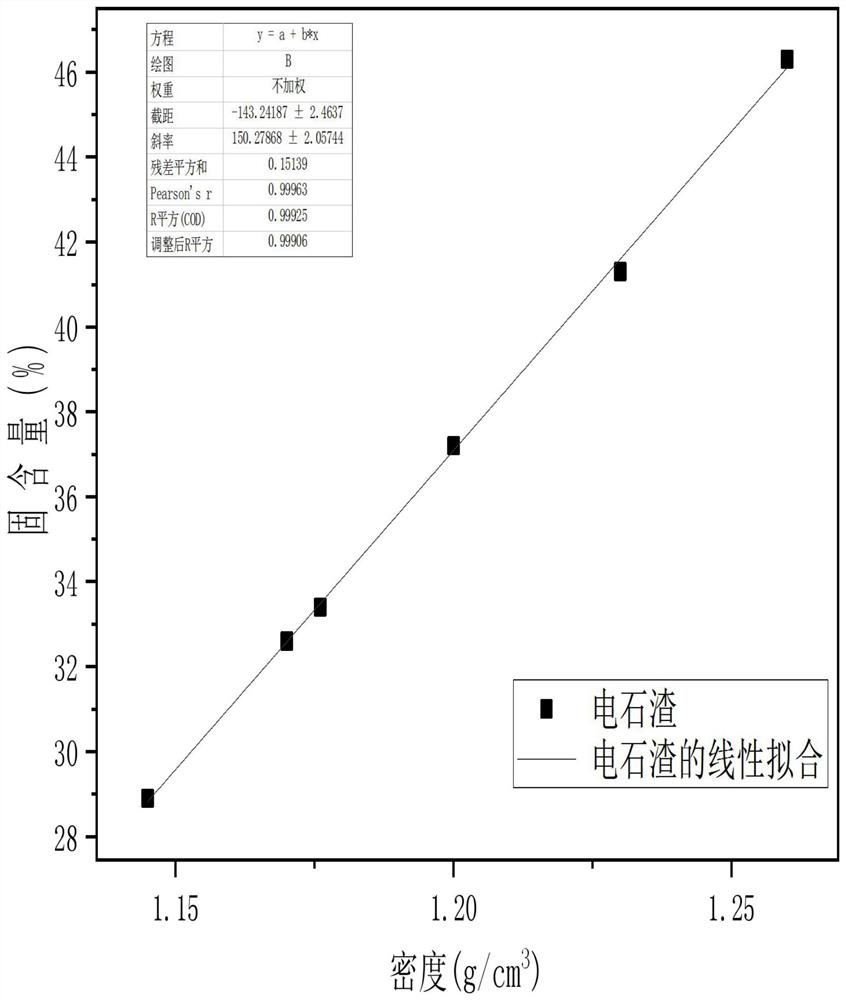

[0034] S1. The required wet-base carbide slag, slag and domestic waste incineration fly ash powder are 450-720 parts of slag, 45-90 parts of calcium carbide slag in terms of solid content, 80-360 parts of domestic waste incineration fly ash, 2600 parts ~2750 parts of sand are mixed, and the supernatant liquid of calcium carbide slag is added to adjust the water-binder ratio to be 0.3 to 0.7, wherein the supernatant liquid of calcium carbide slag is the amount required to remove the water in the wet-base carbide slag;

[0035] S2. take a certain amount of the above-obtained mixed slurry and place it in a brick-making machine mold to press and form to obtain a brick blank;

[0036] S3. Put the bricks at a temperature of 40 to 70 °C for 12 to 24 hours, and then put them in a standard curing condition of a temperature of 18 to 24 °C with a relative humid...

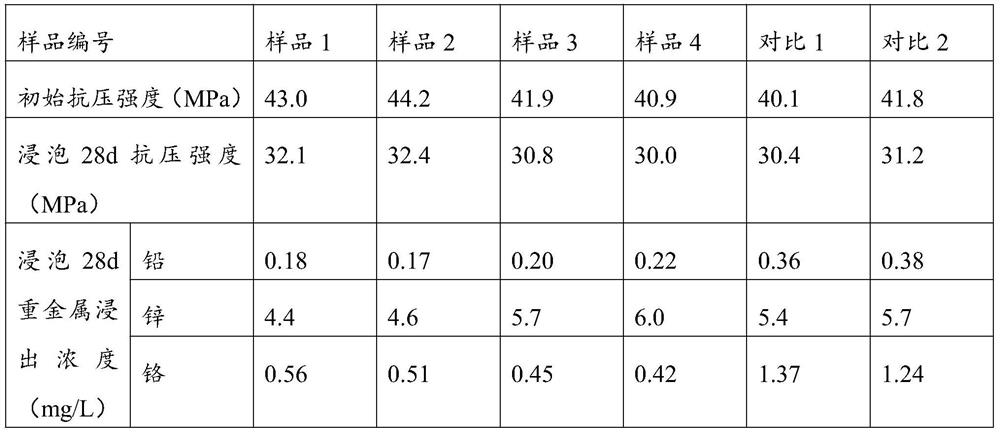

Embodiment 1

[0053] Mineral slag, carbide slag, domestic waste incineration fly ash, carbide slag, river sand, per m 3 The mass (kg) is calculated as: 720 parts of slag, 180 parts of household waste incineration fly ash, 45 parts of calcium carbide slag, and 2600 parts of river sand.

[0054] The weight parts of wet-base carbide slag, slag, and domestic waste incineration fly ash are 45 parts of calcium carbide slag, 720 parts of slag, and 180 parts of domestic waste incineration fly ash. The required wet-base carbide slag, slag and domestic waste incineration fly ash powder are added to the mixer, and after stirring, a certain proportion of river sand is added, and the supernatant of calcium carbide slag is added according to the proportion of water added. The required addition amount of water in the calcium carbide slag is obtained to obtain a composite cementitious material mixture.

[0055] A certain amount of the mixed slurry obtained above was placed in a brick-making machine mold f...

Embodiment 2

[0058] Slag, carbide slag, domestic waste incineration fly ash, river sand, per m 3 The mass (kg) is calculated as: 630 parts of slag, 270 parts of household waste incineration fly ash, 50 parts of carbide slag, and 2650 parts of river sand.

[0059] The weight parts of wet-base carbide slag, slag, and domestic waste incineration fly ash are 50 parts of calcium carbide slag, 630 parts of slag, and 270 parts of domestic waste incineration fly ash. The required wet-base carbide slag, slag and domestic waste incineration fly ash powder are added to the mixer, after stirring, a certain proportion of river sand is added, and the calcium carbide slag supernatant is added according to the water ratio. The added calcium carbide slag supernatant is used to remove moisture. The required addition amount of water in the calcium carbide slag is obtained to obtain a composite cementitious material mixture.

[0060] A certain amount of the mixed slurry obtained above was placed in a brick-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com