Hydrogenation catalyst and production thereof

A catalyst and tungsten oxide technology, which is applied in chemical instruments and methods, through the hydrogenation of aromatic hydrocarbons, physical/chemical process catalysts, etc., can solve the problem of low catalyst activity and achieve the effect of activity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

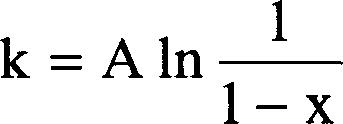

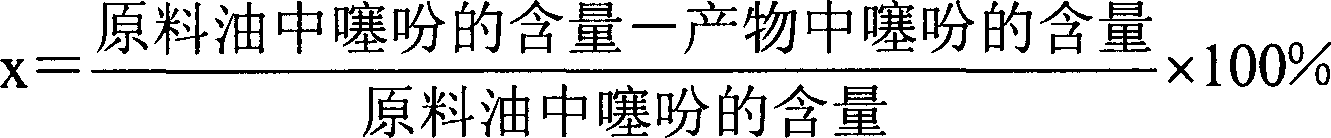

Method used

Image

Examples

example 1

[0026] Take by weighing 4000 grams of aluminum hydroxide dry rubber powder (product of Changling Refining and Chemical Company Catalyst Factory), extrude into a clover-shaped bar with a circumscribed circle diameter of 1.3 mm, and dry the wet bar at 120° C. for 4 hours, then bake it at 600° C. for 4 hours. Vector S1 is obtained.

[0027] Get 100 grams of carrier S1, impregnate 1 hour with 88 milliliters of aqueous solution containing 6.7 grams of ammonium paramolybdate (chemically pure, Beijing Chemical Plant product), dry at 120° C. for 4 hours, and after being down to room temperature, use nickel nitrate containing (analytical pure, Beijing chemical factory product) 10.5 grams, ammonium metatungstate (industrial grade, product of Sichuan Zigong Cemented Carbide Factory) 27.4 grams of aqueous solution 84 milliliters impregnated for 1 hour, dried at 120 DEG C for 4 hours and roasted at 450 DEG C for 4 hours to obtain catalyst C1 . The composition of catalyst C1 after calcinat...

example 2

[0029] Take 100 grams of the carrier S1 prepared in Example 1, soak it with 88 ml of an aqueous solution containing 6.6 grams of ammonium paramolybdate for 1 hour, dry at 120°C for 4 hours, and after cooling down to room temperature, add 13.0 grams of nickel nitrate and 34.4 grams of ammonium metatungstate 83 ml of aqueous solution was impregnated for 1 hour, dried at 120° C. for 4 hours, and then calcined at 450° C. for 4 hours to obtain catalyst C2. The composition of catalyst C2 after calcination is listed in Table 1.

example 3

[0033] Take 200 grams of the carrier S1 prepared in Example 1, impregnate the carrier with 176 ml of an aqueous solution containing 21.4 grams of ammonium paramolybdate for 1 hour, dry at 120°C for 4 hours, and after cooling down to room temperature, use 71.6 grams of nickel nitrate, metatungstic acid 162 ml of aqueous solution of 129.4 g of ammonium was impregnated for 1 hour, dried at 120° C. for 4 hours, and then calcined at 350° C. for 4 hours to obtain catalyst C3. The composition of catalyst C3 after calcination is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com