Uniform macromeritic tungsten powder and method for preparing tungsten carbide powder

A coarse-grained, tungsten carbide technology, used in the field of refractory metal smelting, can solve the problems of many distorted grains, poor grain shape, and poor crystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

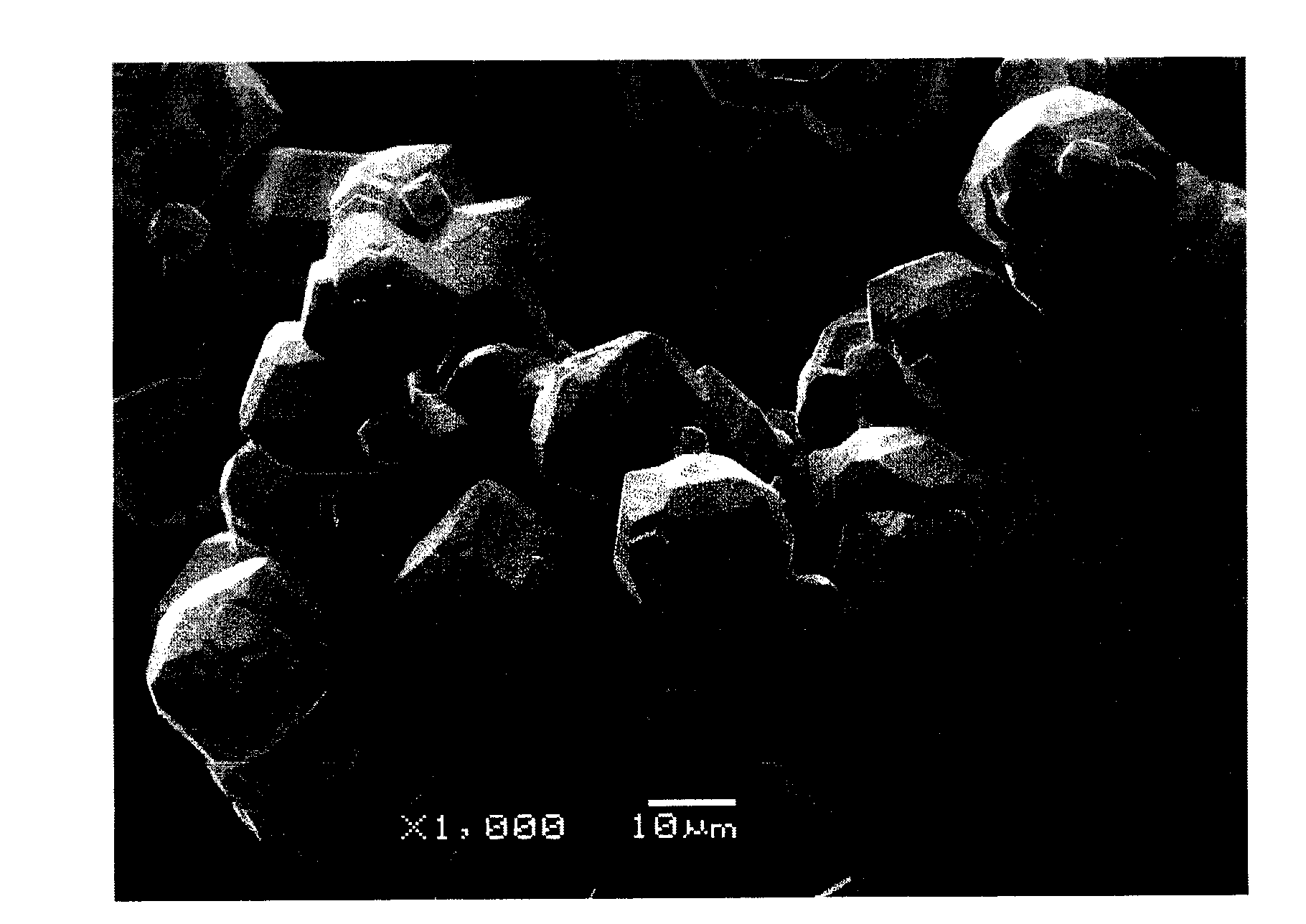

[0016] Example 1: Use blue tungsten oxide powder with a Fsss particle size (the same below) of about 20 μm as raw material, with about 6 kg of raw material per boat. Raise the temperature of the reduction furnace to 1000°C, feed water vapor and hydrogen into the furnace, and control the P H20 / P H2 is 0.45. Then push into the material boat and reduce for about 15 hours. After discharge, sieve and remove scale to obtain coarse-grain tungsten powder with a Fsss particle size of about 21 μm. The morphology of the obtained coarse-grained tungsten powder is as attached figure 1 As shown, it can be seen that the crystal grains of tungsten powder particles are very coarse, relatively uniform, with very little fine powder, and good particle crystallization.

[0017] The obtained coarse-grained tungsten powder is carbonized according to a known method, with a carbon content of 6.15%, and then put into a carbonization furnace for carbonization. The carbonization temperature is 2300 °...

Embodiment 2

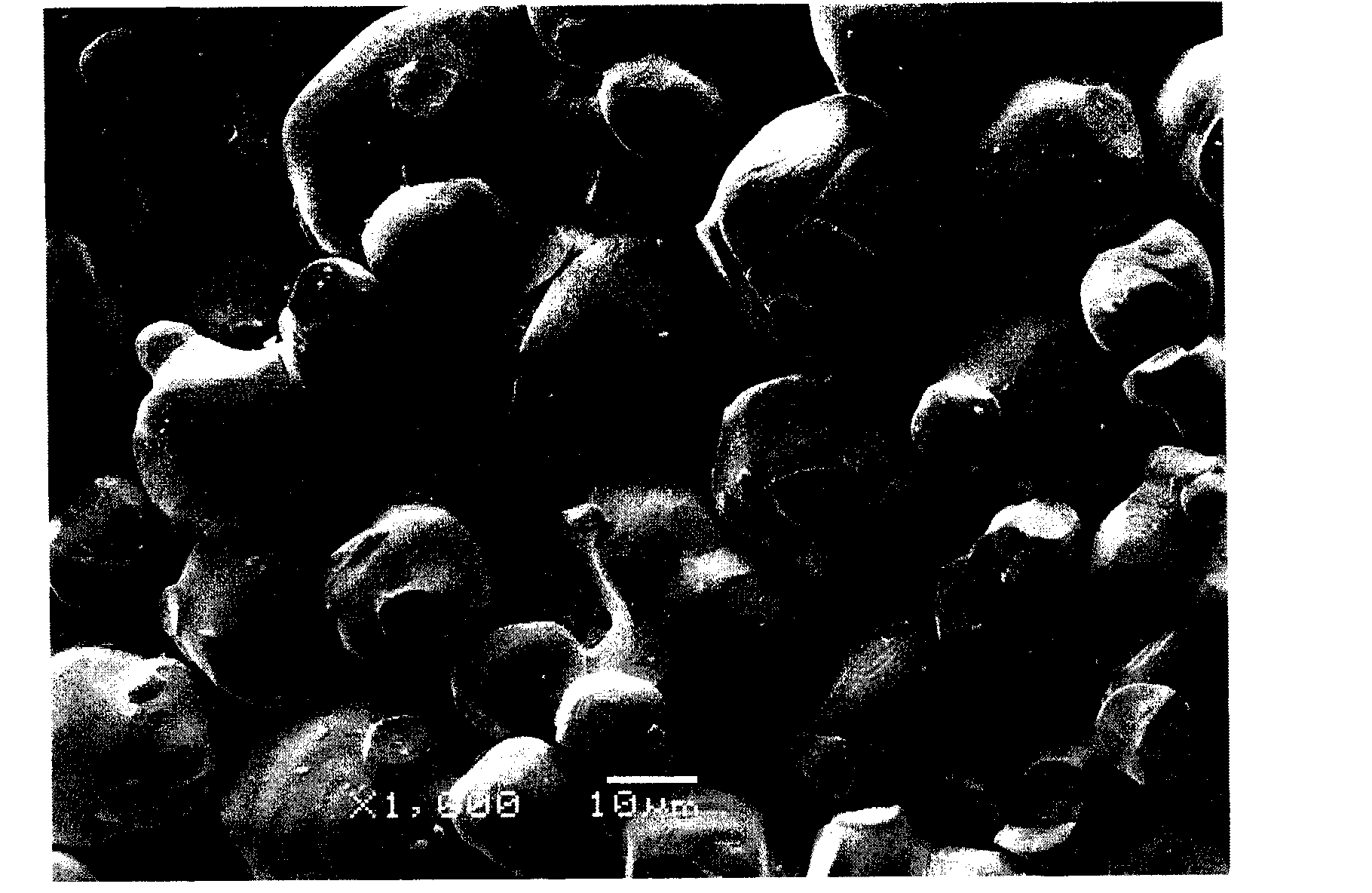

[0019] Embodiment 2: The coarse-grain tungsten powder obtained in Example 1 is mixed with carbon according to a known method, and the amount of carbon is 6.15%, and then put into a carbonization furnace for carbonization. The carbonization temperature is 2300 ° C, the carbonization time is 5 hours, and the carbonization atmosphere is Ar. After the furnace temperature drops to the temperature that can be released from the furnace, the material is discharged, and then processed in the same manner as in Example 1 to obtain coarse-grained tungsten carbide powder. The particle size of the obtained coarse-grained tungsten carbide powder is about 24 μm, and the appearance is similar to that attached figure 2 shown.

Embodiment 3

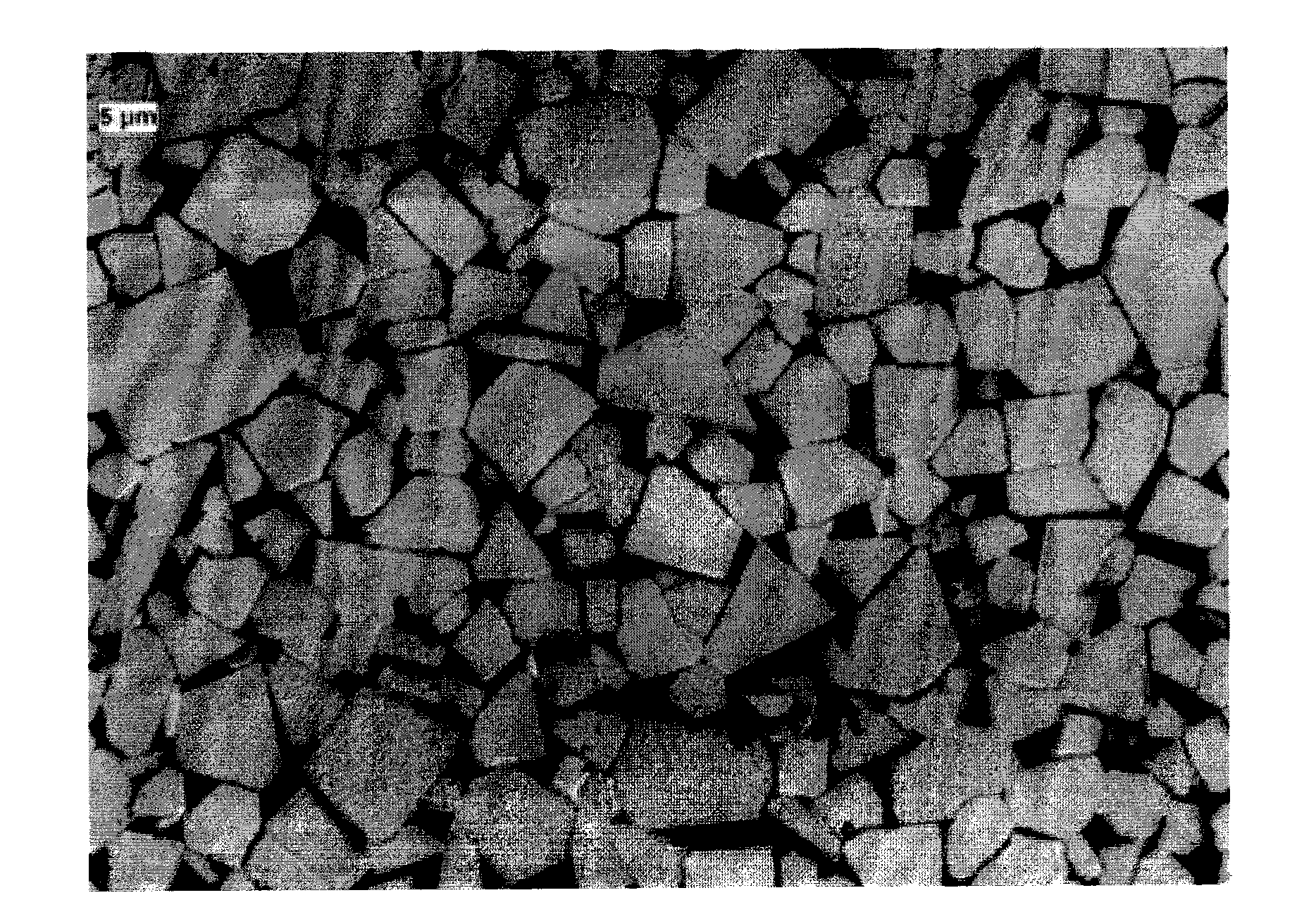

[0020] Example 3: Add tungsten powder with a weight ratio of about 5% and a particle size of about 3 μm into the blue tungsten oxide powder of about 20 μm, mix it for 1 to 2 hours and then load it into a boat, and each boat is filled with about 6Kg of the above mixed raw material . Raise the temperature of the reduction furnace to 1000°C, feed water vapor and hydrogen into the furnace, and control the P H20 / P H2is 0.5. Then push into the material boat and reduce for about 10 hours. After discharge, sieve and remove scale to obtain coarse-grained tungsten powder with a Fsss particle size of about 27 μm. The morphology of the obtained coarse-grained tungsten powder is as attached Figure 4 As shown, it can be seen that the crystal grains of the tungsten powder particles are coarser than that of Example 1, and also very uniform, with good crystallization.

[0021] The obtained coarse-grain tungsten powder is carbonized in the same manner as in Example 1, and the particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com