Liquefied petroleum gas-coke gasoline hydrogenation combined process method

A technology for liquefied petroleum gas and coking gasoline, applied in the field of combined processes, can solve the problems of high content of dilute hydrocarbons in hydrocoking gasoline, difficult to achieve the quality of raw materials for catalytic reforming and steam cracking, and can reduce reaction temperature and reduce catalyst carbon deposition. , the effect of increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

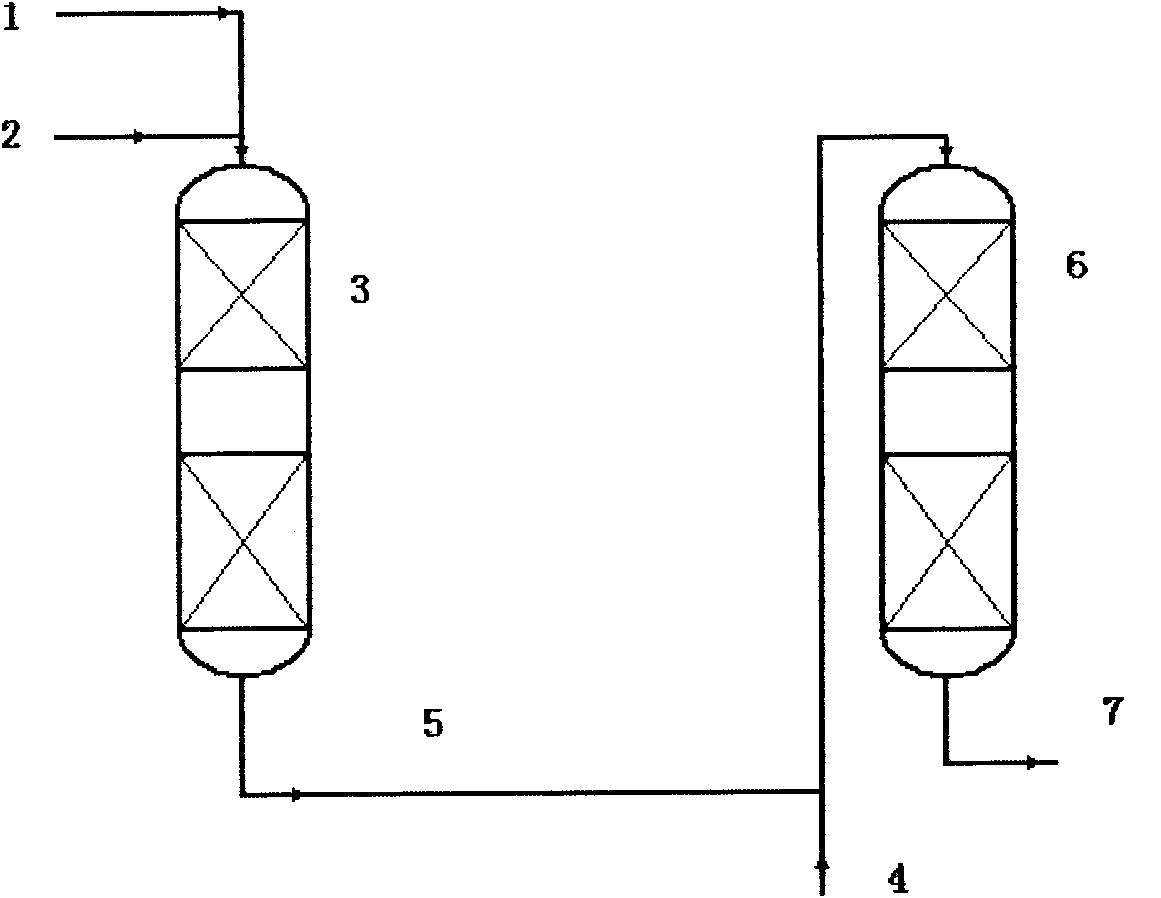

Method used

Image

Examples

Embodiment 1~8

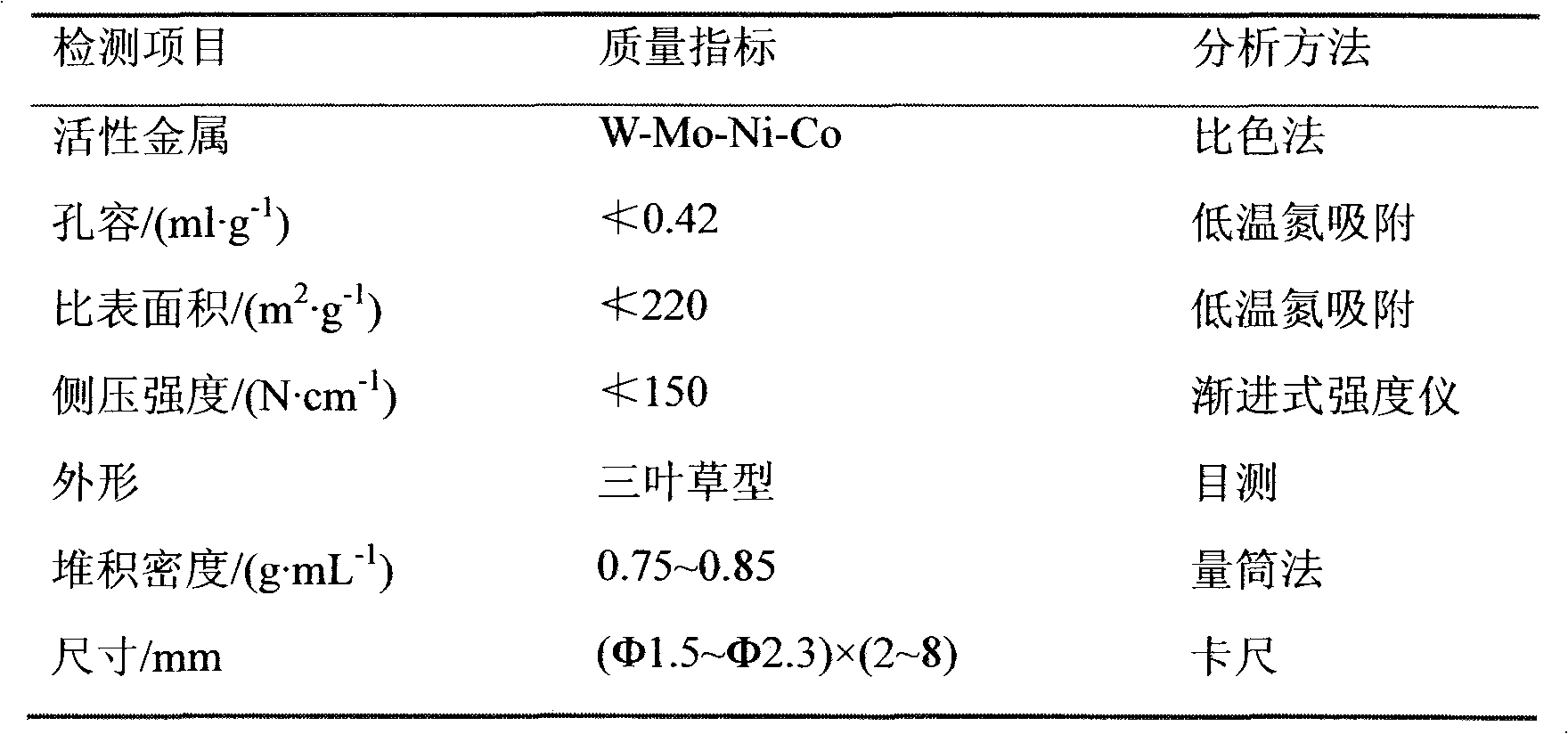

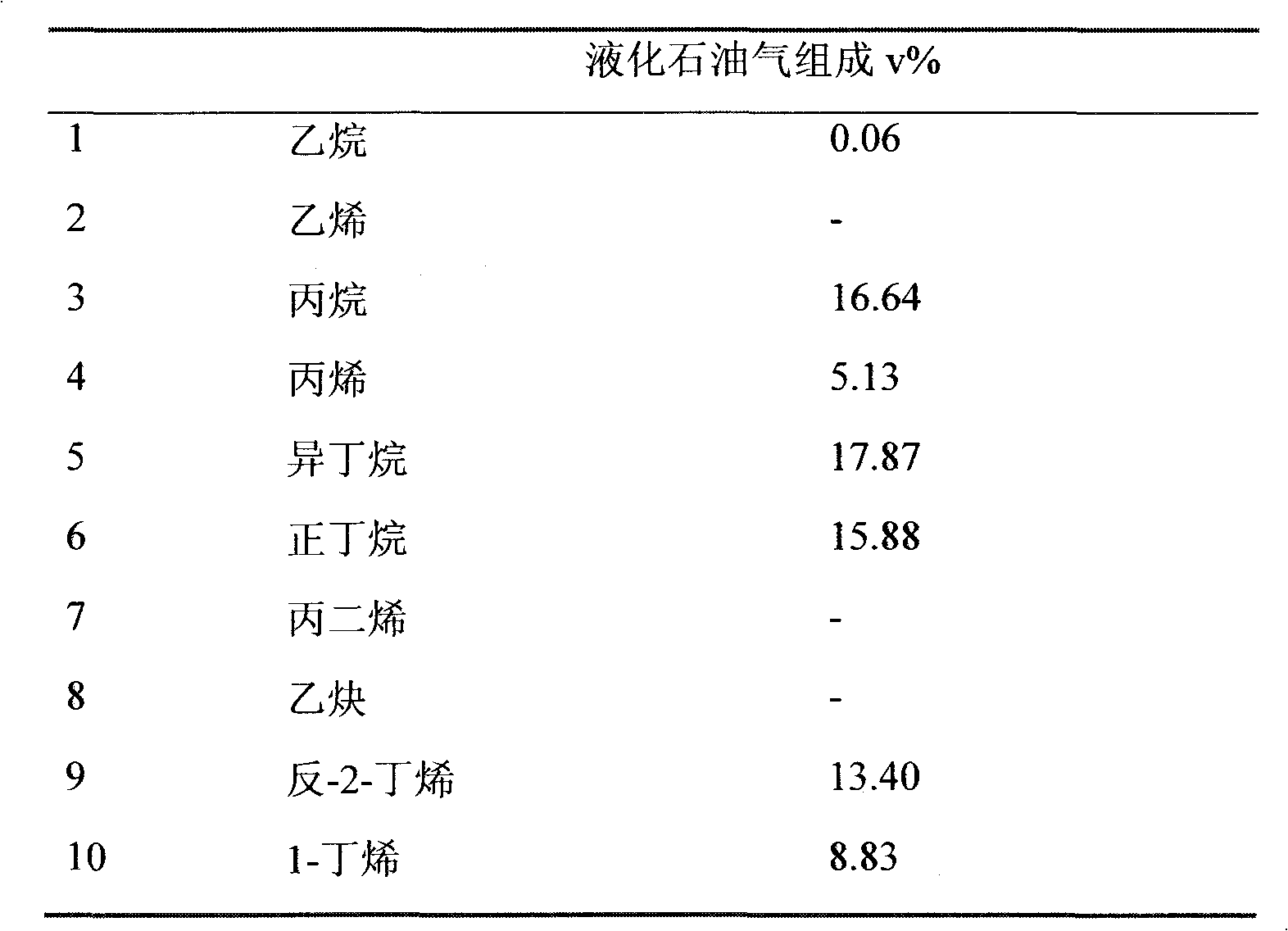

[0049] Take 100ml of FH-40C catalyst and put it into a stainless steel reactor with an inner diameter of 25mm and a length of 1200mm. Reaction raw materials: hydrogen is electrolytically purified hydrogen with a purity of >99%; the C4 fraction is obtained from Fushun Petroleum No. The reaction is upper feed, the reaction material flows out from the bottom of the reactor, and enters the separator after cooling, the tail gas is discharged from the top of the separator, the liquid phase at the bottom is regularly sampled, and the composition is analyzed by gas chromatography. The specific reaction conditions and results are listed in Table 7 .

[0050] Table 6 Main properties of hydrocoking gasoline feedstock

[0051]

[0052] Table 7 Experimental conditions and results

[0053]

[0054] From the data in Table 7, it can be seen that the mixed feed method of liquefied petroleum gas and coker gasoline can not only hydrogenate the two materials at the same time, but also gre...

Embodiment 9

[0056] The stability experiment of the scheme of the present invention, concrete reaction condition and result are listed in Table 8.

[0057] Table 8 Experimental conditions and results

[0058]

[0059] As can be seen from the data in Table 8, when the catalyst activity stability experiment was finished, the catalyst had been operated for 800 hours, and the catalyst still had good activity, indicating that the process of the present invention had better activity and stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com