Super-soft high-elasticity hydrolysis resistance high-stripping wet polyurethane resin and preparation method thereof

A polyurethane resin and high-elasticity technology, applied in the field of polyurethane resin, can solve the problems of low modulus and high strength, and achieve the effects of high peel strength, good hydrolysis resistance and uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

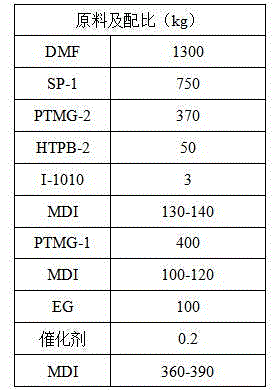

[0053] Raw materials and ratio:

[0054]

[0055] 1) Add 750kg of SP-1, 370kg of PTMG-2, 50kg of HTPB-2 and 3kg of antioxidant I-1010 into the organic solvent DMF to form a solution with a solid content of 30%; stir well and then add 130- 140kg of isocyanate was reacted at 45-50°C for 1-2 hours; then the remaining 400kg of PTMG-1 was added to continue the reaction for 2 hours, and then 100-120kg of isocyanate was added to make the hydroxyl group in the polyol compound and the isocyanate group in the diisocyanate The molar ratio is 1:1.5; finally react at 65°C to obtain a prepolymer with a solid content of 55% and a viscosity of 80 Pa·s / 75°C;

[0056] 2) Add 100 kg of chain extender EG, 360-390 kg of isocyanate and 0.2 kg of organic bismuth catalyst (BiCAT? 8106, produced by a leading American chemical company) to the prepolymer, stir evenly, and continue at 75-85°C React for 2-5 hours. During the reaction, the organic solvent is continuously added as the viscosity of the s...

Embodiment 2

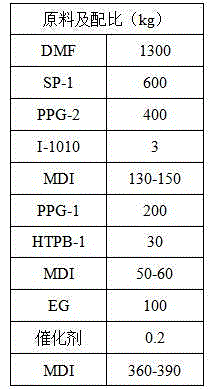

[0059] 1. Raw material and ratio:

[0060]

[0061]1) Add 600kg of SP-1, 400kg of PPG-2, 200kg of PPG-1 and 3kg of antioxidant I-1010 into the organic solvent DMF to form a solution with a solid content of 20%; stir well and then add 130 -150kg of isocyanate was reacted at 45°C for 1 hour; then the remaining 30kg of HTPB-1 was added to continue the reaction for 1 hour, and then 50-60 kg of isocyanate was added to make the molar ratio of the hydroxyl group in the polyol compound to the isocyanate group in the diisocyanate 1:1.5; finally react at 55°C to obtain a prepolymer with a solid content of 45% and a viscosity of 30Pa·s / 75°C;

[0062] 2) Add 100 kg of chain extender EG, 360-390 kg of isocyanate and 0.2 kg of organic bismuth catalyst (BiCAT? 8106, produced by a leading American chemical company) to the prepolymer, stir well, and continue to react at 75°C for 2 hours During the reaction process, the organic solvent is continuously replenished as the viscosity of the sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com