A wet polyurethane resin for impregnation with high tear strength and hydrolysis resistance and preparation method thereof

A high tear strength, polyurethane resin technology, used in textiles, papermaking, fiber processing, etc., can solve problems such as non-environmental protection, and achieve the effect of improving peel strength, increasing peel strength, and high product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

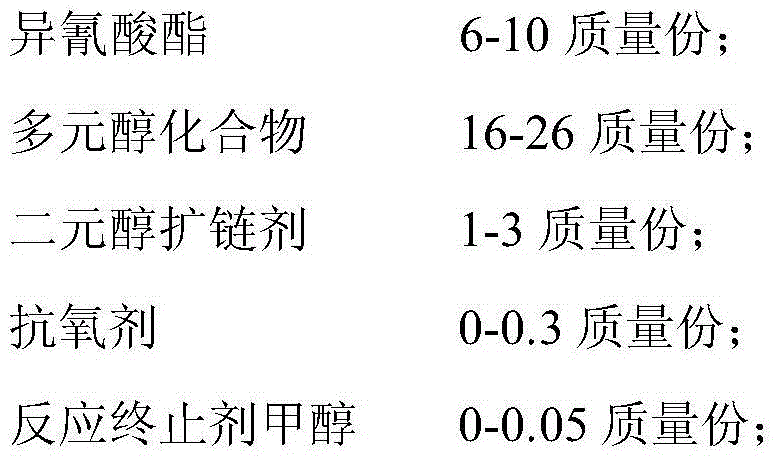

[0038] 1. Raw material and ratio:

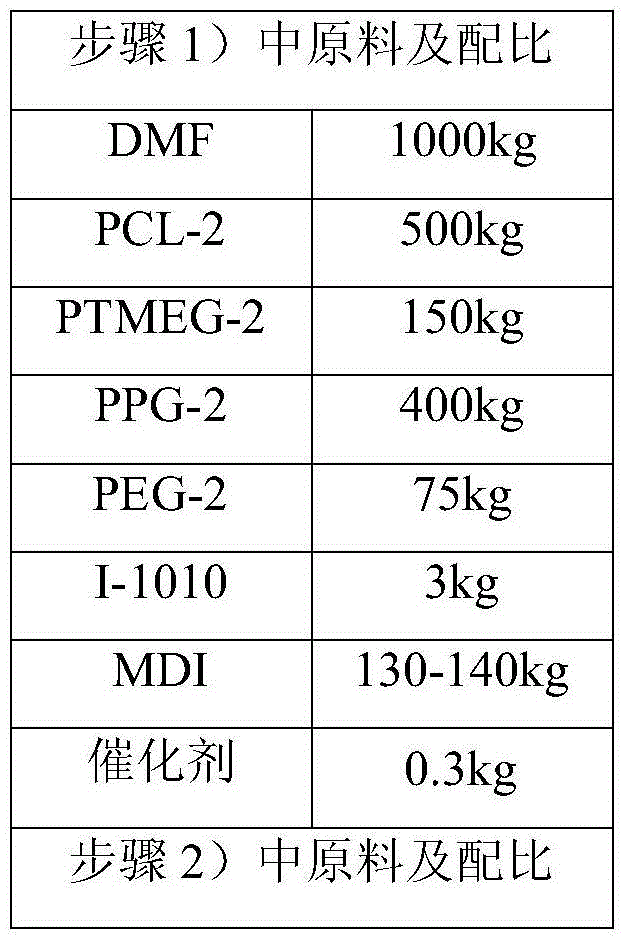

[0039]

[0040]

[0041] 2. Preparation method:

[0042] 1) Add the polyol compounds PCL-2, PTMEG-2, PPG-2 and PEG-2 and the antioxidant I-1010 into the solvent DMF, stir well and then add MDI and organic bismuth catalyst BiCAT8106 (leading American chemical company Production), react at 75-85°C for 1-3 hours to obtain a prepolymer with a solid content of 55%;

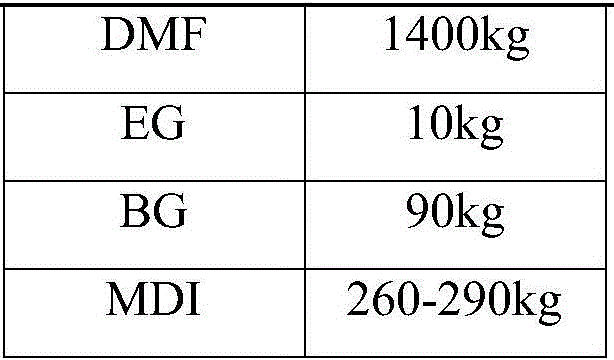

[0043] 2) Add glycol chain extenders EG and BG and the rest of MDI to the prepolymer prepared in step 1), stir evenly, and continue to react at 75-85°C for 2-5h, during the reaction process As the viscosity of the system increases, the organic solvent is continuously replenished so that the final viscosity is controlled at 40000-80000cps / 25°C. After the reaction is completed, 0.5-2kg of reaction terminator methanol is added.

Embodiment 2

[0045] 1. Raw material and ratio:

[0046]

[0047] 2. Preparation method:

[0048] 1) Add polyol compounds SP-1, PTMEG-2, PPG-2 and PEG-2 and antioxidant I-1010 into the solvent DMF, stir well and add MDI and organic bismuth catalyst BiCAT8106 (leading American chemical company Production), react at 75-85°C for 1-3 hours to obtain a prepolymer with a solid content of 55%;

[0049] 2) Add glycol chain extenders EG and BG and the rest of MDI to the prepolymer prepared in step 1), stir evenly, and continue to react at 75-85°C for 2-5h, during the reaction process As the viscosity of the system increases, the organic solvent is continuously replenished so that the final viscosity is controlled at 40000-80000cps / 25°C. After the reaction is completed, 0.5-2kg of reaction terminator methanol is added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com