Multi-functional wool-worsted western-style clothes fabric

A wool worsted, multi-functional technology, applied in clothing, textile, clothing and other directions, can solve the problems of no breaking strength and tearing strength, and no heat preservation function, and achieve super breaking strength and tearing strength, Excellent waterproof, good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

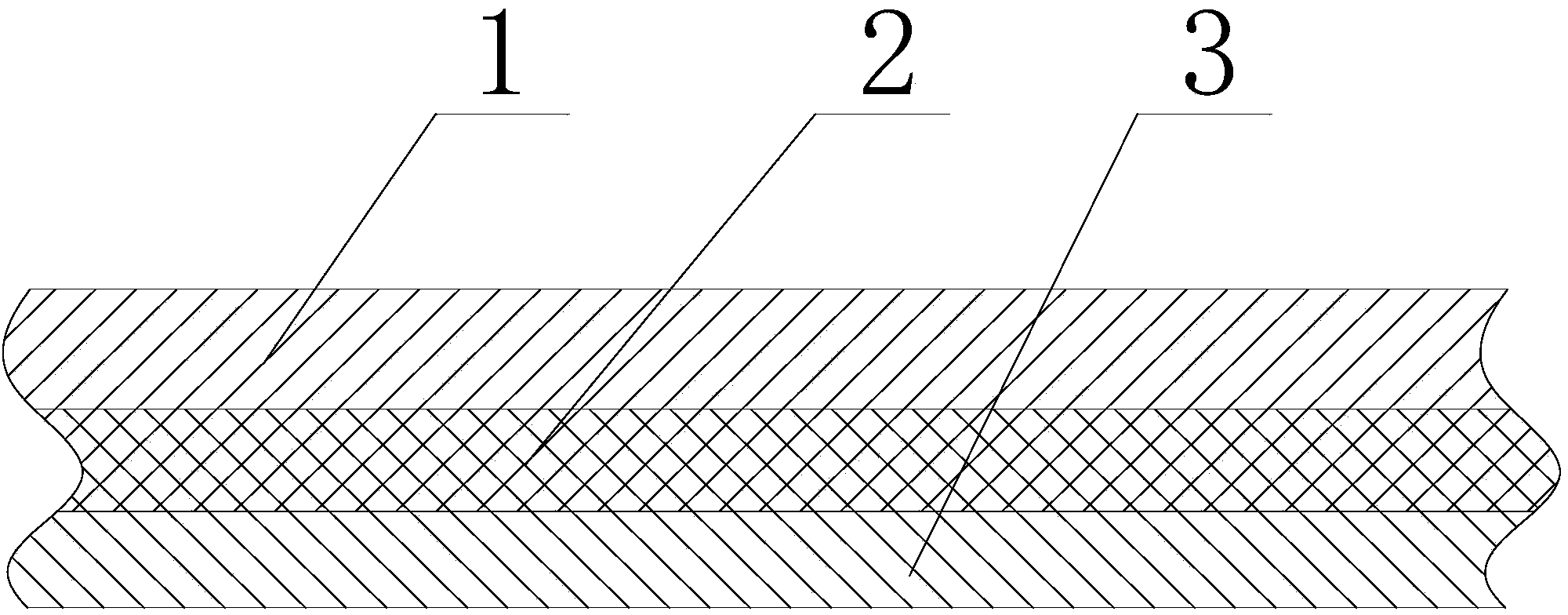

[0019] like figure 1 Said, a multi-functional wool worsted suit fabric, comprising a surface layer 1, a middle layer 2 and an inner layer 3, the middle layer 2 is used as a basis to connect the surface layer 1 and the inner layer 3.

[0020] The surface layer is a surface layer woven from surface yarns, and the surface yarns are surface yarns woven from aramid-based conductive fibers with a length of 20-45mm. The middle layer is braided by middle layer yarns, and the middle layer yarns are made by blending Thermolite hollow fiber and aramid fiber with a length of 25-40mm. The inner layer is woven from the inner layer yarn, and the inner layer yarn is woven from Australian wool with a length of 50-80mm.

[0021] In this embodiment, the Thermolite hollow fiber is a Thermolite hollow fiber with a length of 20-45 mm and a fineness of 1.4-1.6 dtex. The aramid fiber is an aramid fiber with a length of 20-45mm and a fineness of 1.3-2.0dtex. The aramid-based conductive fiber is an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com