Cashmere carding combination machine

A combined machine and carding technology, used in deburring devices, textiles and papermaking, fiber processing, etc., to improve the removal effect, improve the extraction rate, and improve the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

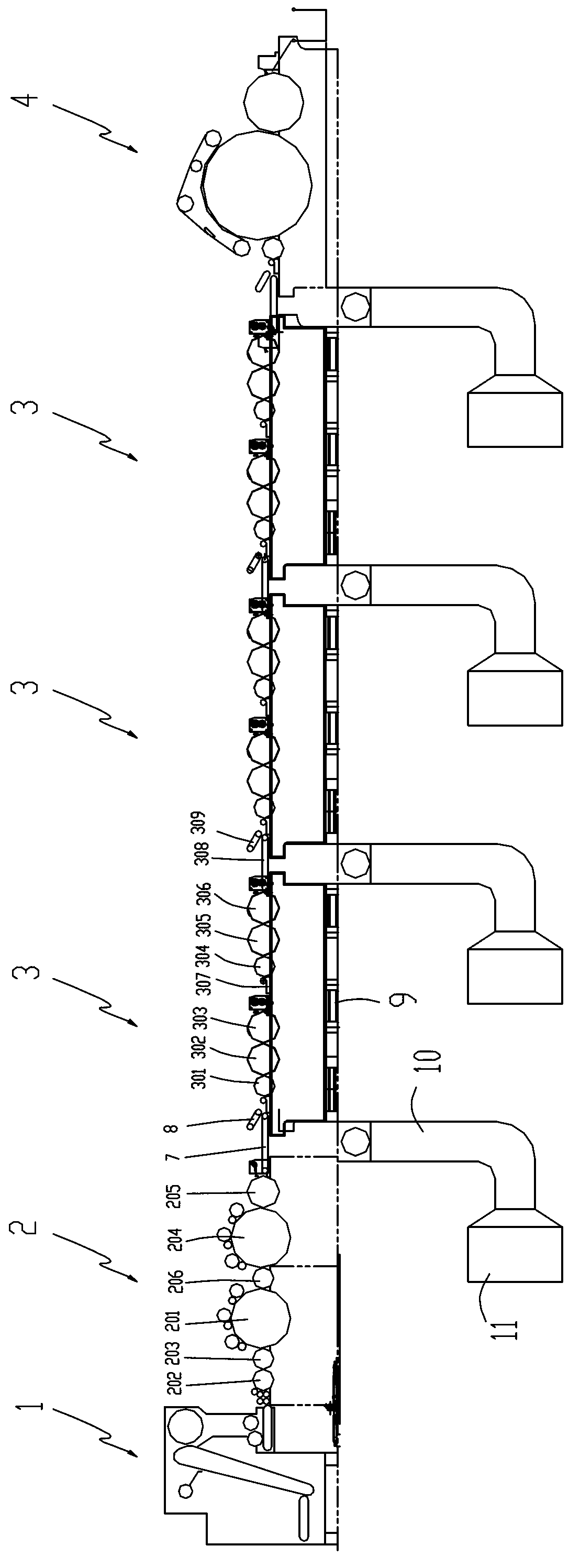

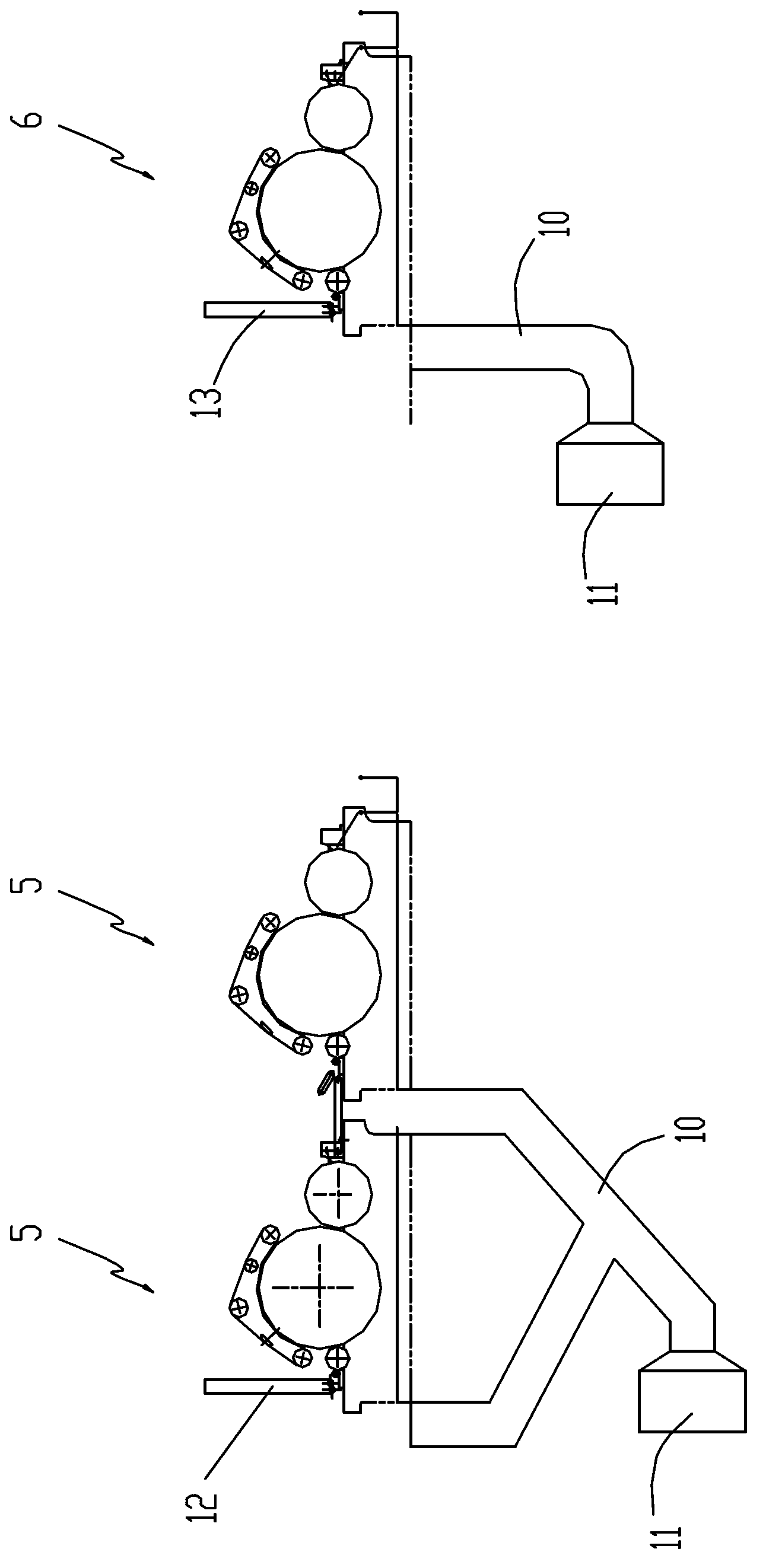

[0013] combine figure 1 and figure 2 , a combined cashmere carding machine, comprising a wool feeder 1, an opener 2, a plurality of coarse throwing and impurity removal units 3 and a plurality of flat carding machines. The above-mentioned opening machine includes a first opening unit and a second opening unit. The first opening unit includes a No. 1 opening cylinder 201, and several pairs of work roll groups are arranged on the No. 1 opening cylinder. An opener licker-in roller 202 is arranged between the opening unit and the wool feeding machine. The purpose of setting the opener licker-in roller on this part is to further enhance the opening effect. Transfer rollers 203 are arranged between the forests. The second opening unit includes the No. 2 opening cylinder 204 and the opening machine doffer 205. Several pairs of work roll groups are arranged on the No. 2 opening cylinder. A transfer roller 206 is arranged between the cylinder and the No. 2 opening cylinder. This ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com