Main carding mechanism of interlaced fabric carding machine

A technology of non-woven fabrics and carding machines, which is applied in the direction of roll forming mechanism, textile and paper making, fiber processing, etc., and can solve problems such as unsuitable raw materials, difficulty in completely transferring to web forming rollers, and card clothing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

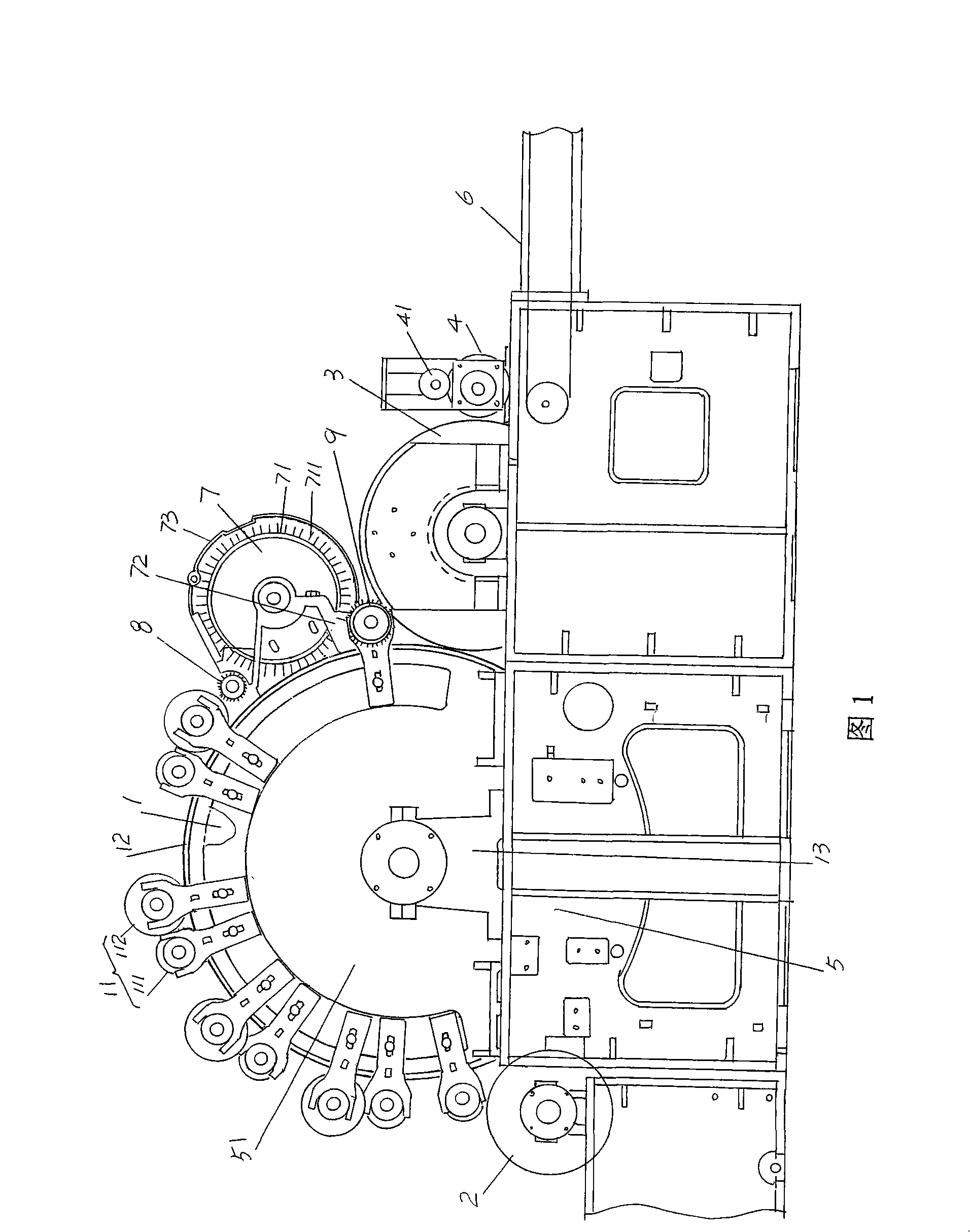

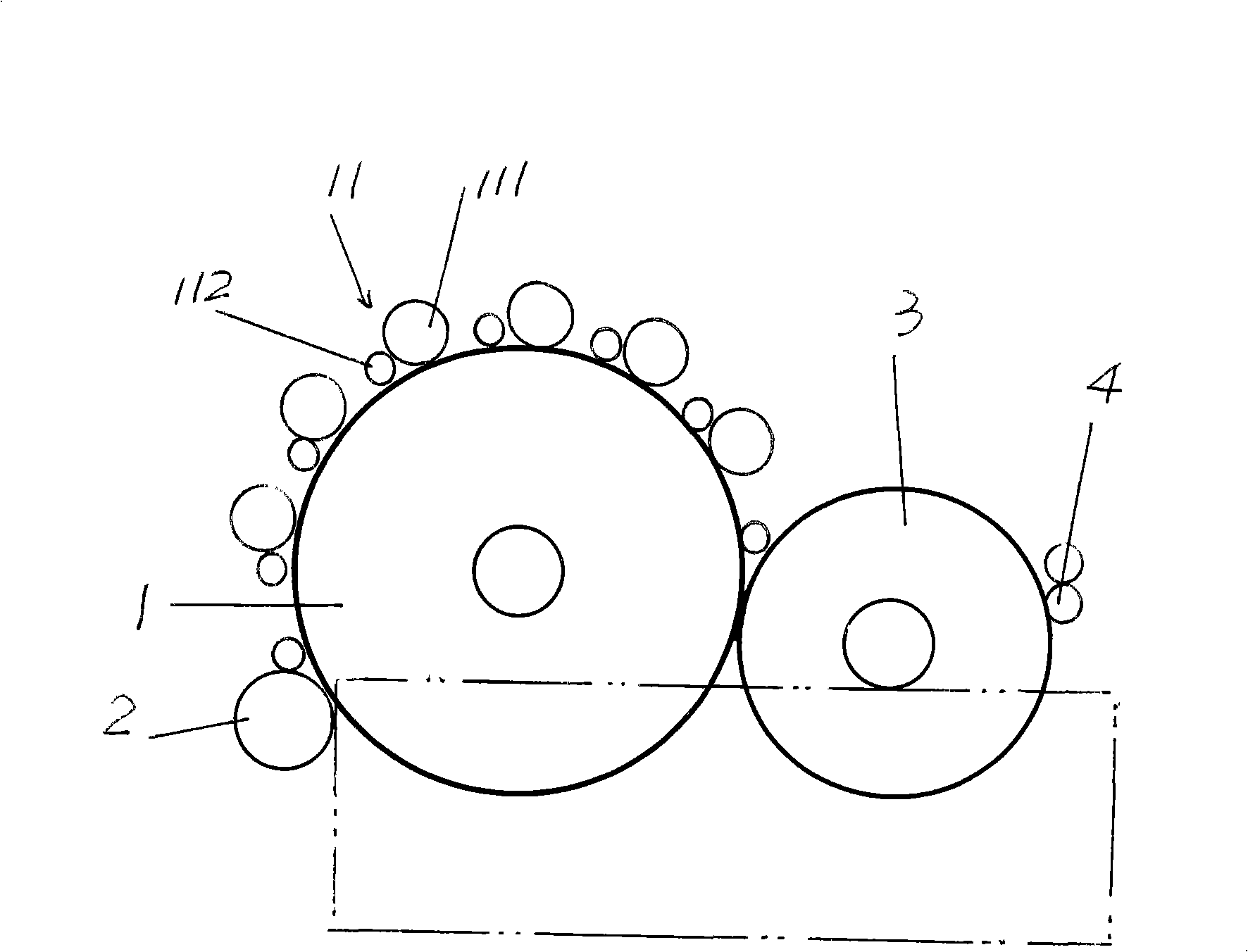

[0018] Please refer to Fig. 1, have provided the frame wallboard 51 of one side in a pair of frame 5 of the main carding mechanism of nonwoven carding machine, on the wallboard 51 of this frame 5, pass axle seat support 13 A main carding cylinder 1 is pivoted, and the surface of the cylinder body of the main carding cylinder 1 is coated with a main carding cylinder card clothing 12, and four groups of carding units 11 are arranged on the wallboard 51, and each group of carding units 11 includes The working roll 111 and the stripping roll 112 that work in cooperation with each other, the cooperative work mentioned here refers to the glass fiber that has been pre-stripped by the pre-stripping mechanism that is transferred (transferred) by the transfer roll 2 The short fiber is stripped by the stripping roller 112, and at the same time, it is coordinated by the working roller 111 and transferred to the card clothing 12 of the main carding cylinder for the web forming roller 3 behi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com