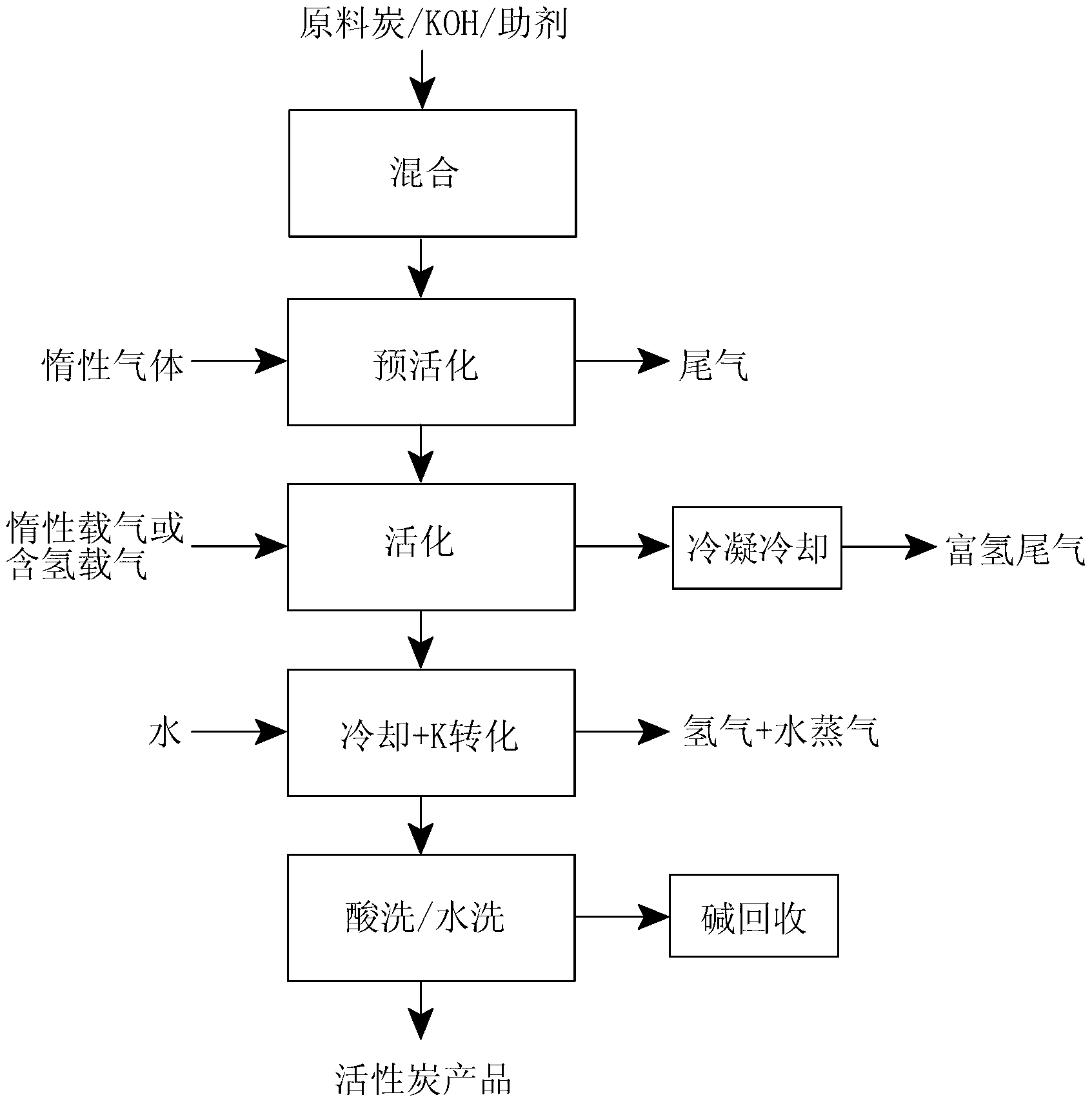

Continuous alkali activation device and method for preparing activated carbon with high specific surface area

A high specific surface area, activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of low unit capacity, potential safety hazards, and high energy consumption, to eliminate potential safety hazards, reduce production costs, The effect of reducing alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

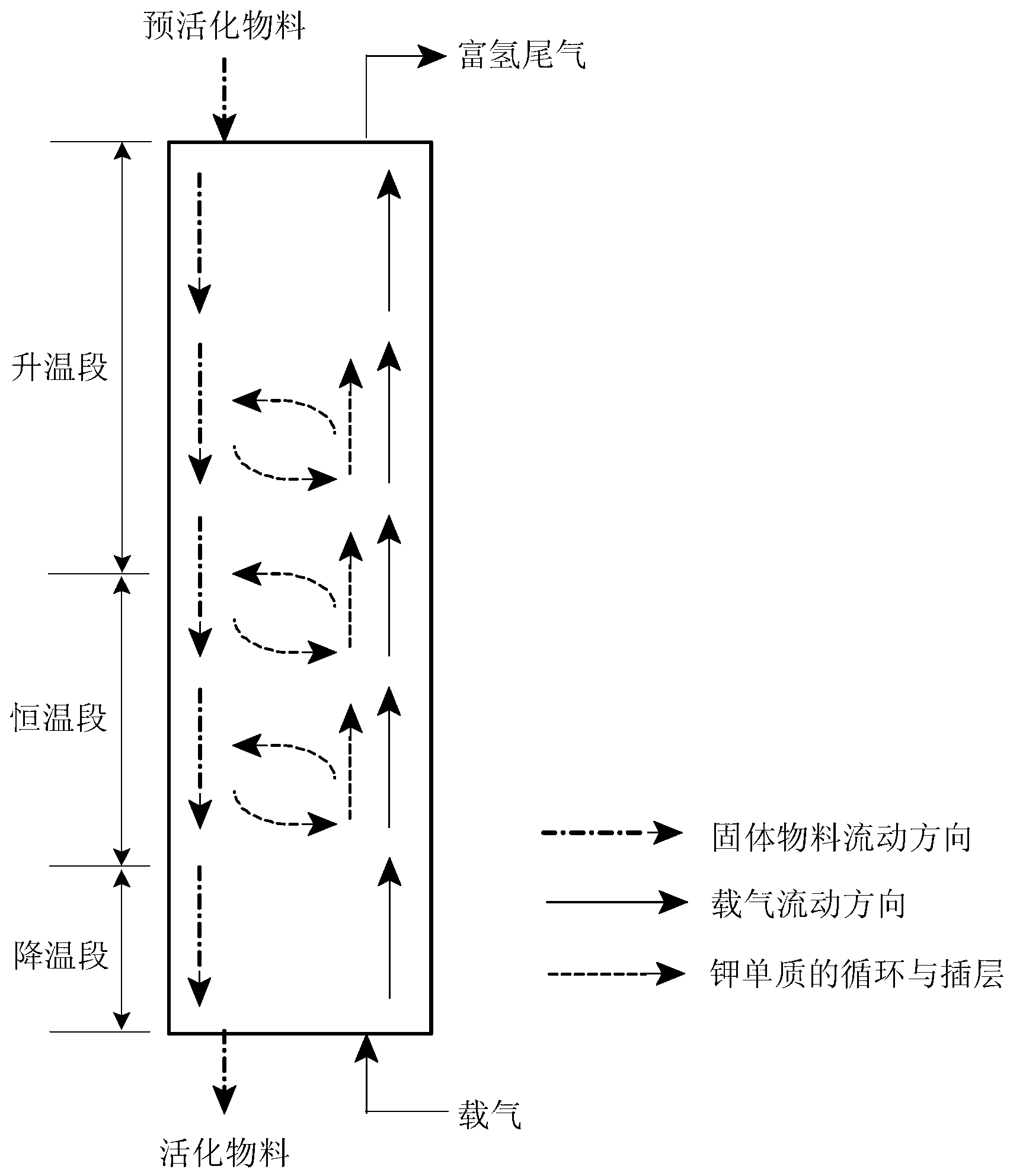

Method used

Image

Examples

Embodiment 1

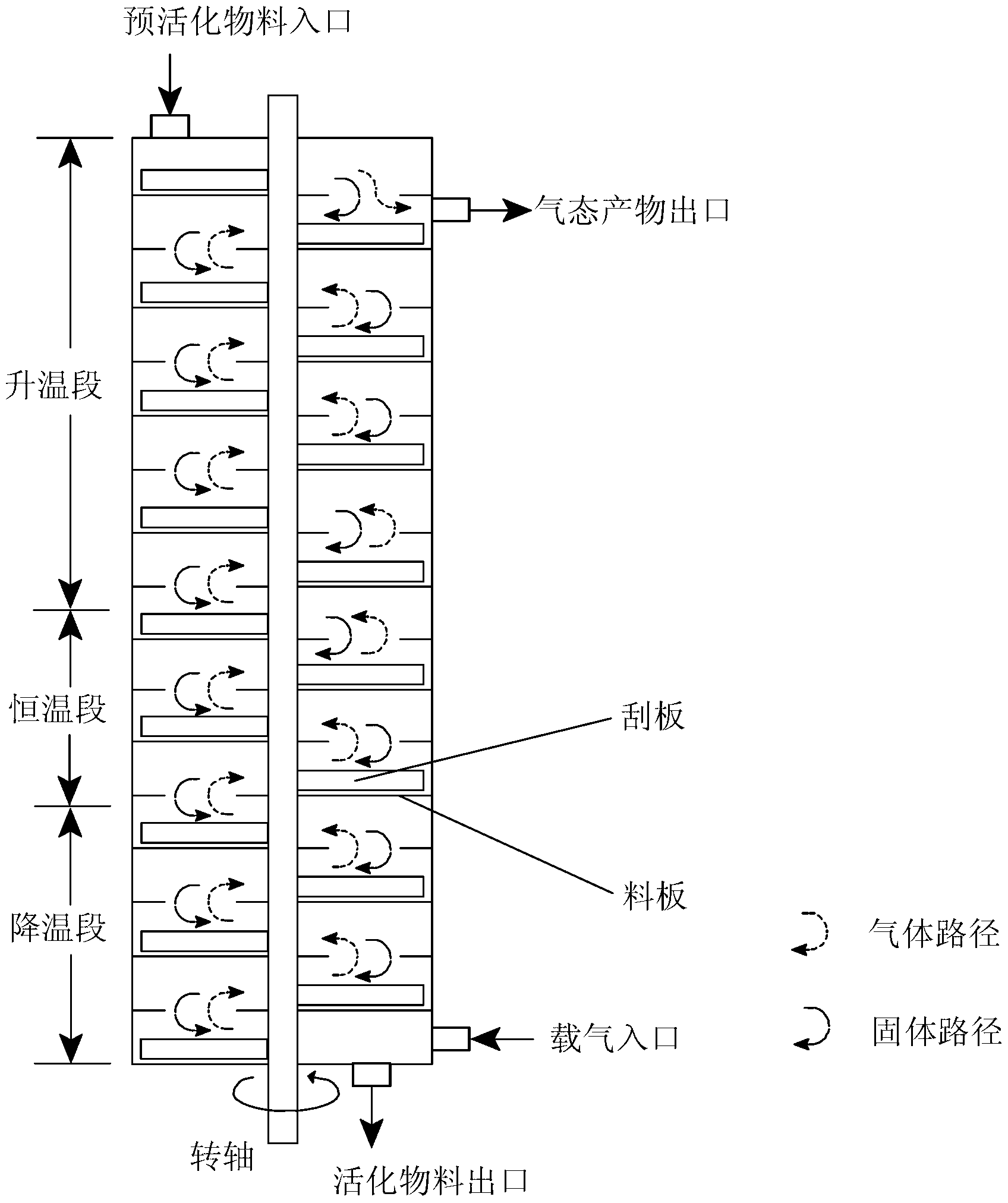

[0033] The KOH activation experiment of raw carbon is carried out in the experimental device, and the operation process principle of the experimental device is attached figure 1 ~ attached Figure 4 , where the pre-activation reactor and the vertical activation furnace are independently controlled separately. The main technical parameters of the experimental device are as follows: the pre-activation furnace is a single-screw extrusion type, in which the screw extrusion chamber is 400mm long, and the heating section is 150mm long; the vertical activation furnace is made of high-temperature and corrosion-resistant stainless steel, with an effective height of 1206mm and an inner diameter of 120mm. The number of sheets is 45 layers, and the fan-shaped central angle α formed by the blanking holes of the sheets is 120 o , the total opening rate is 25%, and the position stagger angle β of the fan-shaped arrangement of the two adjacent material plates is 180 o ; The activation furn...

Embodiment 2

[0041] The main technical parameters of the experimental device The fan-shaped central angle α formed by the blanking hole of the material plate is 60 o , the total opening rate is 12%, and other parameters are the same as in Example 1. Under this condition, when the rotating speed of the central shaft is 0.57r / min, the total residence time of the pre-activated alkali-carbon mixture in the furnace is 86min, and it stays in the heating section. The time is 32min, the residence time in the constant temperature section is 34min, and the residence time in the cooling section is 20min.

[0042] Using anthracite as raw material, the particle size is less than 250μm, the mass ratio of anthracite / KOH is 3:1; the temperature of the preactivation heating section is 400°C, and the residence time of the material passing through the heating section of the preactivation reactor is about 10min; the temperature distribution of the heating section of the activation furnace The temperature in t...

Embodiment 3

[0046] The main technical parameters of the experimental device The fan-shaped central angle α formed by the blanking hole of the material plate is 30 o , the total opening rate is 5%, and other parameters are the same as in Example 1. Under this condition, when the rotating speed of the central shaft is 0.57r / min, the total residence time of the preactivated alkali-carbon mixture in the furnace is 95min, and it stays in the heating section. The time is 35min, the residence time in the constant temperature section is 38min, and the residence time in the cooling section is 22min.

[0047] Equally with anthracite raw material, other conditions are with embodiment two. The specific surface area and pore volume of different batches of activated carbon products are shown in Table 4.

[0048] Table 4 Specific surface area and pore volume of different batches of activated carbon products

[0049] Sample No.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com