Method for extracting gallium and germanium from zinc smelting slag

A technology of zinc smelting slag and extraction method, which is applied in the field of extracting gallium and germanium from zinc smelting slag, to achieve the effects of reducing acid consumption, saving alkali consumption and reducing waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

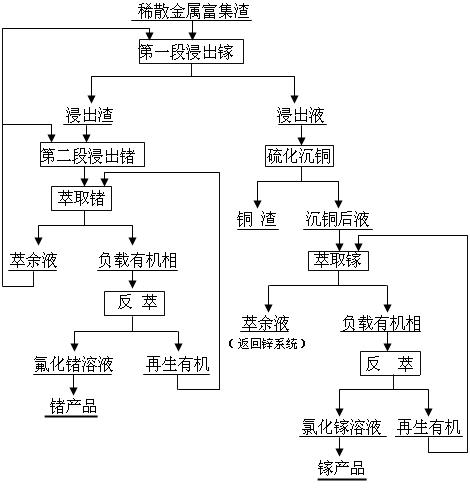

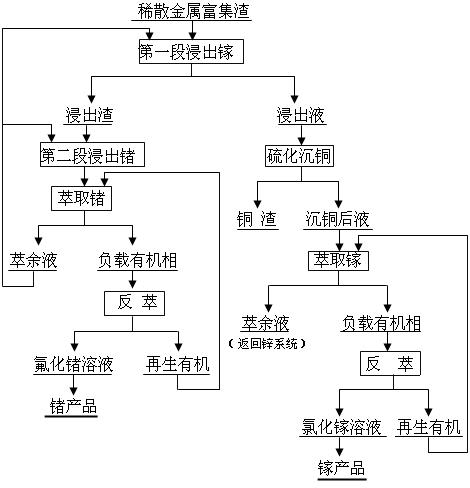

Method used

Image

Examples

Embodiment 1

[0024] The dilute metal-enriched slag used in the experiment is the dilute metal-enriched slag obtained from the pressure leaching solution of zinc concentrate by lime neutralization-zinc powder replacement method, and its chemical composition is shown in Table 1.

[0025] Table 1 Chemical composition of scattered metal-enriched slag

[0026] element Ca Zn Cu Fe S Pb Sb Sn Ga Ge content(%) 19.2 16.58 11.71 5.77 16.3 1.21 0.71 0.17 0.25 0.22

[0027] The first stage leaching conditions are: take 200g of the above-mentioned scattered metal-enriched slag, add 600mL of water, add an appropriate amount of sulfuric acid, keep the pH of the solution in the range of 1.8~2.2, keep stirring and blowing air, the leaching temperature is 60~80℃, and the leaching temperature is 60~80℃. Time 6 hours.

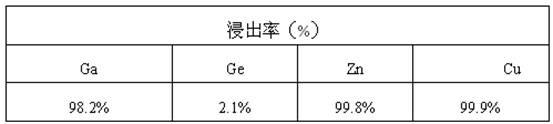

[0028] The results of the leaching experiment:

[0029] Table 2 The results of the first stage leaching experiment

[0030]

Embodiment 2

[0032] The leaching conditions of the second stage are: take 100 g of the leaching residue obtained by the first stage leaching, add 200 mL of the raffinate after germanium extraction as a leaching agent, the raffinate used as a leaching agent contains 45 g / L of sulfuric acid, and the leaching temperature is 60~80 ° C , Supplementing sulfuric acid appropriately during the leaching process, so that the sulfuric acid content of the leaching solution is maintained in the range of 40~60g / L, and the leaching time is 6 hours. The leaching rate of germanium in the second stage is 99.1%.

Embodiment 3

[0034] Using the gallium-containing leaching solution obtained by the first stage leaching, the solution obtained after removing copper by sulfide precipitation is the feed solution,

[0035] (1) Extraction conditions

[0036] Gallium extraction liquid composition Ge 0.016g / L, Ga 0.81g / L, Zn 19.7g / L, Fe 1.64g / L H 2 SO 4 3.2g / L.

[0037] The organic phase consists of:

[0038] Extraction agent: O,O-diisooctylphosphohydroxamic acid, accounting for 10% (v / v)

[0039] Modifier: Isooctanol, 5% (v / v)

[0040] Thinner: 260 # Sulfonated kerosene, accounting for 85% (v / v).

[0041] Compared: O / A=1:2

[0042] Mixing time: 5min

[0043] (2) Extraction results

[0044] The phase separation time was 4 min., the distribution ratio of gallium in the organic phase to the aqueous phase was 60.5, the extraction rate of gallium was 96.8%, and the extraction rate of zinc was 0.4%, indicating that the extraction rate of gallium was very high, and zinc was basically extracted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com