Flax fibers and preparation method thereof

A flax fiber and strength technology, which is applied in the field of flax fiber and its preparation, can solve the problems of poor fiber strength, low flax fiber fineness, low fiber filament fineness, etc., and achieve the effect of wide application and high fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

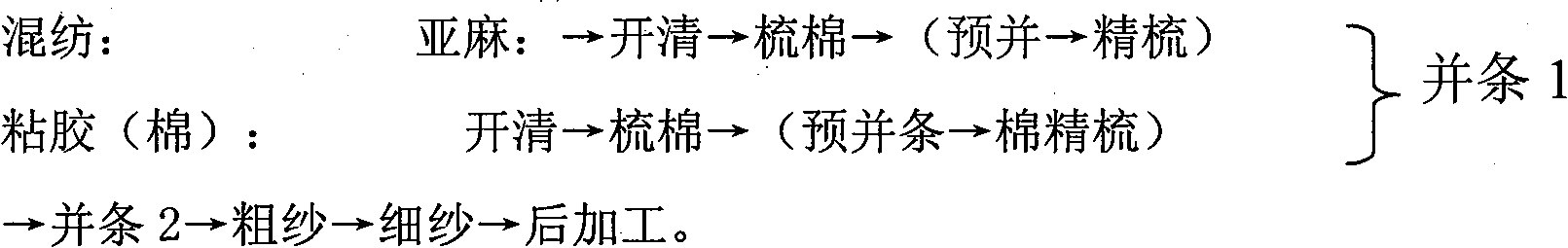

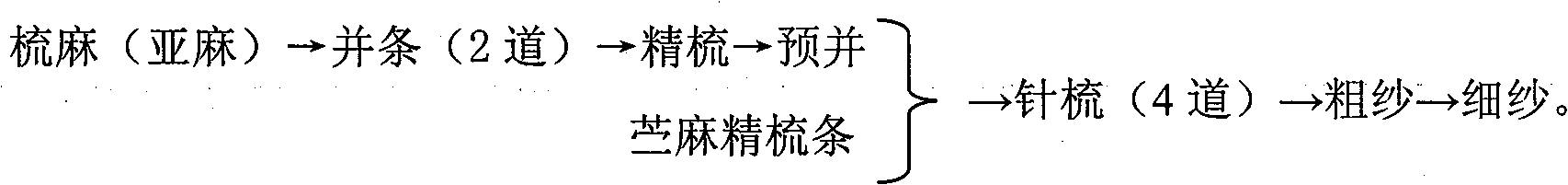

Method used

Image

Examples

Embodiment 1

[0052] Beat flax into hemp and put it in the pickling pool, add 10 kg of water per kg of flax (bath ratio 1:10), add sulfuric acid to make the concentration of sulfuric acid 1g / L. Raise the temperature of the solution to 40°C, keep it warm for 40 minutes, take it out and wash the flax fiber with clean water, so that the pH value of the flax fiber reaches about 7; put the washed flax fiber into the oxidation solution, the bath ratio is 1:10, and oxidize Hydrogen peroxide in liquid (by pure H 2 o 2 Calculation) content is 3g / L, sodium silicate content is 3g / L, potassium carbonate content is 2g / L, urea content is 3g / L, JFC content is 2g / L. Raise the temperature of the oxidizing solution from room temperature to 70°C at a constant speed, and control the heating time at 30 minutes. After reaching the temperature, let the oxidizing solution keep warm for 2 hours; beat the oxidized flax fiber twice with a wooden mallet; The flax fiber is cleaned to remove the medicines and impuriti...

Embodiment 2

[0057] Beat flax into hemp and put it in the pickling pool, add 10 kg of water per kg of flax (bath ratio 1:10), add sulfuric acid to make the concentration of sulfuric acid 2g / L. Raise the temperature of the solution to 50°C, keep it warm for 45 minutes, take it out and wash the flax fiber with clean water, so that the pH value of the flax fiber reaches about 7; put the washed flax fiber into the oxidation solution, the bath ratio is 1:10, Hydrogen peroxide in liquid (by pure H 2 o 2Calculation) content is 4g / L, sodium silicate content is 4g / L, sodium carbonate content is 3g / L, urea content is 4g / L, JFC content is 2g / L. Raise the temperature of the oxidizing solution from normal temperature to 80°C at a constant speed, and control the heating time at 32 minutes. After the temperature reaches, let the oxidizing solution keep warm for 2.2 hours; beat the oxidized flax fiber with a wooden mallet twice; The flax fiber is cleaned to wash away the medicines and impurities remaini...

Embodiment 3

[0062] Beat flax into hemp and put it in the pickling pool, add 10 kg of water per kg of flax (bath ratio 1:10), add sulfuric acid to make the concentration of sulfuric acid 1.5g / L. Raise the temperature of the solution to 42°C, keep it warm for 50 minutes, take it out and wash the flax fiber with clean water, so that the pH value of the flax fiber reaches about 7; put the washed flax fiber into the oxidation solution, the bath ratio is 1:10, and oxidize Hydrogen peroxide in liquid (by pure H 2 o 2 Calculation) content is 5g / L, sodium carbonate content is 4g / L, sodium silicate content is 5g / L, urea content is 5g / L, JFC content is 2g / L. Raise the temperature of the oxidizing solution from room temperature to 90°C at a constant speed, and control the heating time at 34 minutes. After reaching the temperature, let the oxidizing solution keep warm for 2.4 hours; beat the oxidized flax fibers with a wooden mallet for 5 times; The flax fiber is cleaned to wash away the medicines a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com