Activated carbon, preparation method thereof, and application of activated carbon in supercapacitor electrode

A technology of activated carbon and activator, applied in the field of activated carbon, can solve the problems of difficult activation and poor processing performance, and achieve the effects of good reaction and activation, high content of surface functional groups, and favorable regulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Mix 100g of coconut shell powder raw material that has been mechanically crushed to 30 meshes with the activator sodium hydroxide in a solid phase at a mass ratio of 1:2, put it into a corundum crucible, and place it in a medium-temperature box-type resistance furnace under the protection of a nitrogen atmosphere. Raise the temperature at a rate of 2°C / min to 320°C for melt impregnation of the activator, heat preservation treatment for 2 hours; continue to heat up to 700°C at a speed of 2°C / min for activation, and heat preservation for 1 hour; The body was taken out, purified, ball milled, and sieved. Finally, under the protection of nitrogen atmosphere, in a medium-temperature box-type resistance furnace, the temperature was raised to 870°C at a rate of 2°C / min for high-temperature sintering, and heat treatment was performed for 1 hour. Finally, coconut shell-based activated carbon was obtained. Material.

[0074] figure 1 It is the SEM figure of the coconut shell-bas...

Embodiment 2

[0079] Mix 100 g of petroleum coke raw materials mechanically crushed to 30 mesh with activator sodium hydroxide in a solid phase at a mass ratio of 1:3, put it into a corundum crucible, and place it in a medium-temperature box-type resistance furnace under the protection of a nitrogen atmosphere at a temperature of 2 Heat up to 320°C at a speed of ℃ / min for activator melt impregnation, heat preservation treatment for 2 hours; continue to heat up to 800°C at a speed of 2°C / min for activation, heat preservation for 1 hour; after the box furnace cools down, take out the precursor of the activation material , after purification, ball milling, sieving, and finally under the protection of nitrogen atmosphere, in a medium-temperature box-type resistance furnace, the temperature was raised to 400°C at a rate of 2°C / min for high-temperature sintering, heat treatment for 1 hour, and finally petroleum coke-based activated carbon materials were obtained.

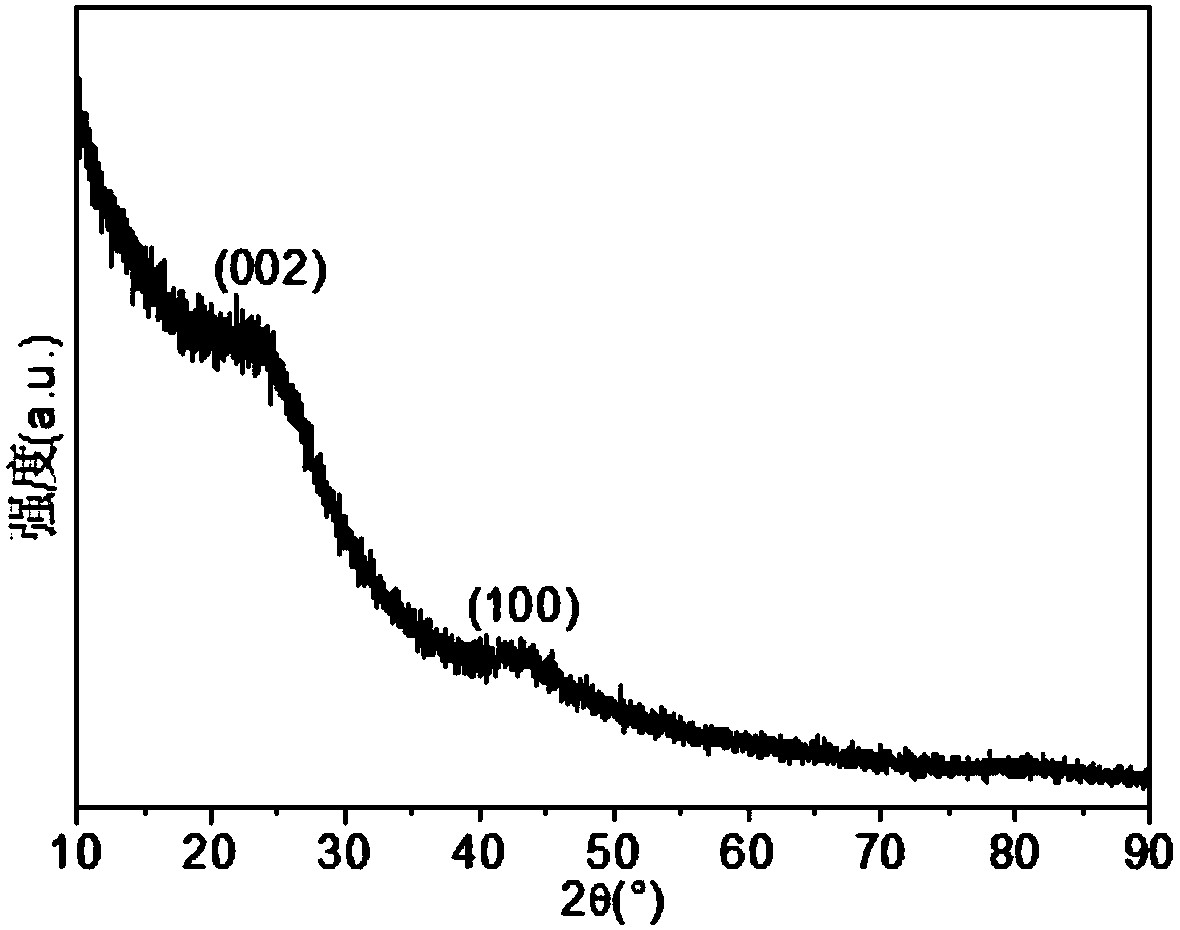

[0080] image 3 Be the XRD patt...

Embodiment 3

[0085] Mix 100g of phenolic resin raw material that has been mechanically crushed to 30 meshes with the activator sodium hydroxide in a solid phase at a mass ratio of 1:2, put it into a corundum crucible, and put it in a medium-temperature box-type resistance furnace under the protection of a nitrogen atmosphere. Heat up to 320°C at a speed of ℃ / min for activator melt impregnation, heat preservation treatment for 2 hours; continue to heat up to 750°C at a speed of 2°C / min for activation, heat preservation for 1 hour; after the box furnace cools down, take out the precursor of the activation material , after purification, ball milling, and sieving, and finally under the protection of nitrogen atmosphere, in a medium-temperature box-type resistance furnace, the temperature was raised to 600°C at a rate of 2°C / min for high-temperature sintering, and heat treatment was performed for 1 hour to finally obtain phenolic resin-based activated carbon.

[0086] The specific surface area o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com