Zirconium oxide/titanium oxide/cerium oxide doped rare earth tantalum/niobate RETa/NbO4 ceramic powder and preparation method thereof

A ceramic powder, titanium oxide technology, applied in chemical instruments and methods, inorganic chemistry, tantalum compounds, etc., to achieve the effect of good fluidity and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

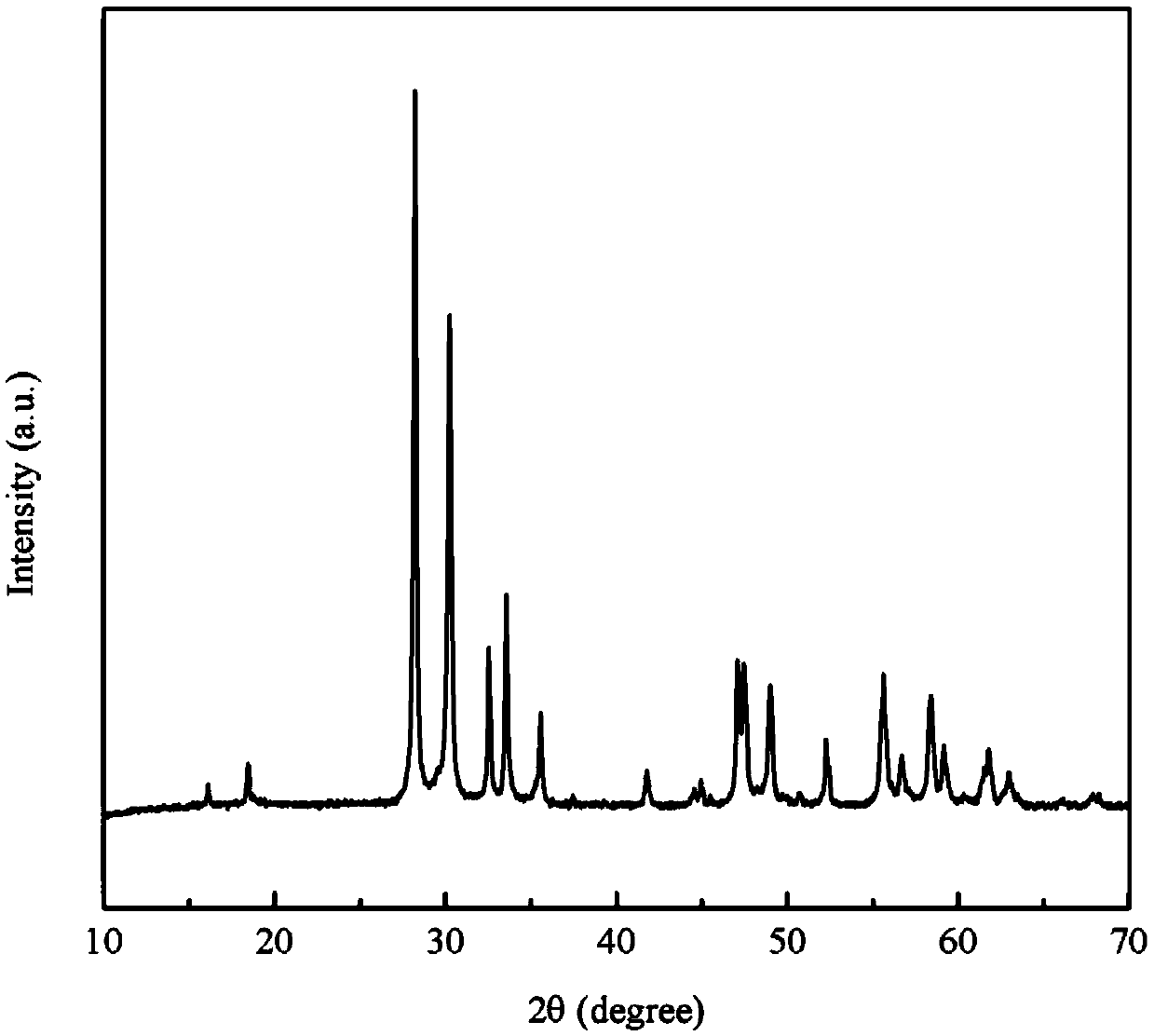

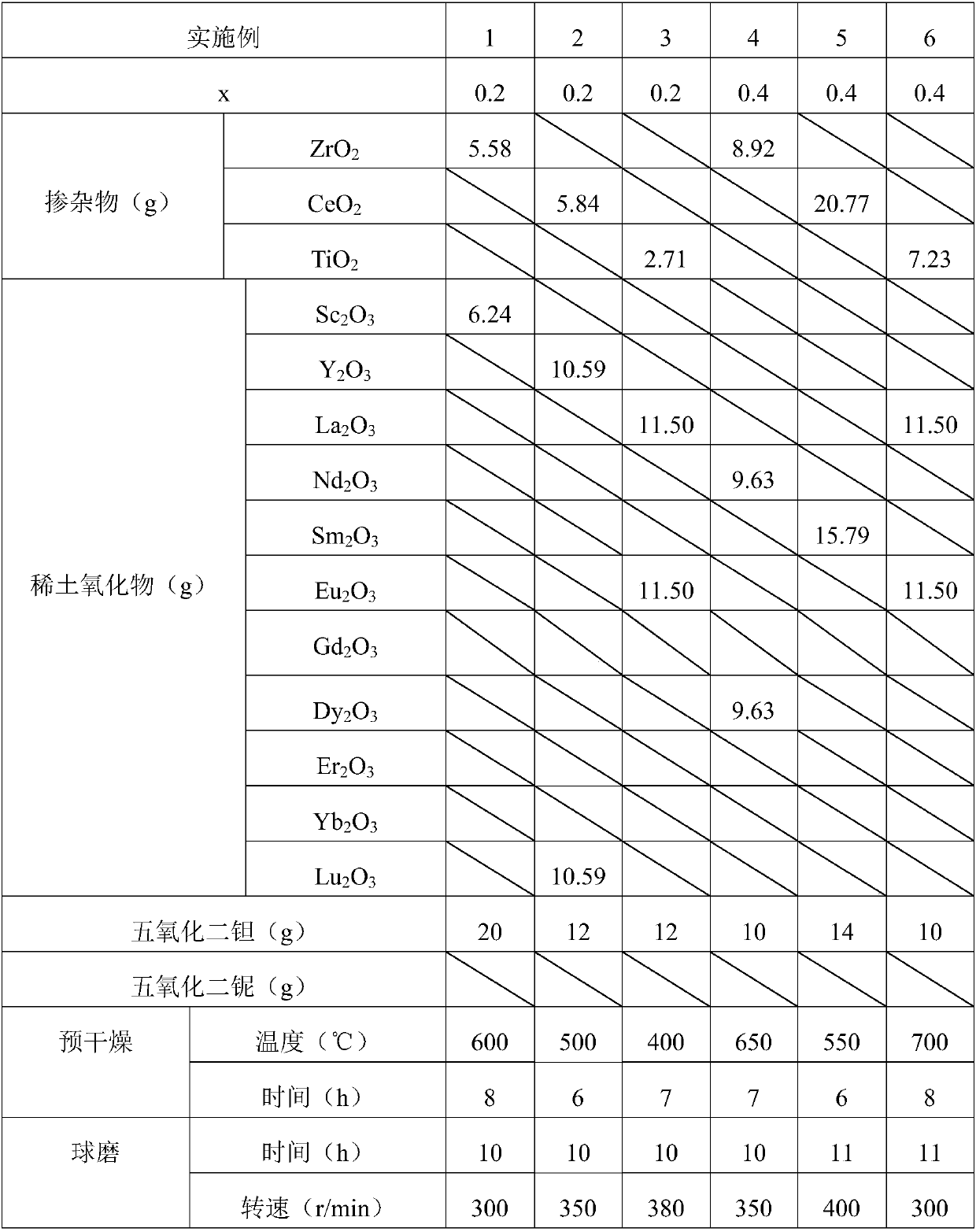

[0053] Zirconia (ZrO 2 ) doped rare earth carbonate (RETaO 4 ) ceramic powder (Sc 0.8 Ta 0.8 Zr 0.4 o 4 ) preparation method, comprising the following steps:

[0054] step 1):

[0055] Zirconia (ZrO 2 ) powder, rare earth oxide powder Sc 2 o 3 , tantalum pentoxide (Ta 2 o 5 ) powder for pre-drying, the pre-drying temperature is 600°C, and the pre-drying time is 8h; and weigh 5.58g zirconia (ZrO 2 ) powder, 6.24g rare earth oxide powder Sc 2 o 3 , 20g tantalum oxide (Ta 2 o 5 ) powder into the ethanol solvent to obtain a mixed solution, so that the molar ratio of Sc:Ta:Zr in the mixed solution is 2:2:1; then use a ball mill to mill the mixed solution for 10 h, and the speed of the ball mill is 300r / min.

[0056] The slurry obtained after ball milling was dried using a rotary evaporator (model: N-1200B) at a drying temperature of 60°C and a drying time of 2 hours. The dried powder was sieved through a 300-mesh sieve to obtain powder A.

[0057] Step (2):

[0058...

Embodiment 1

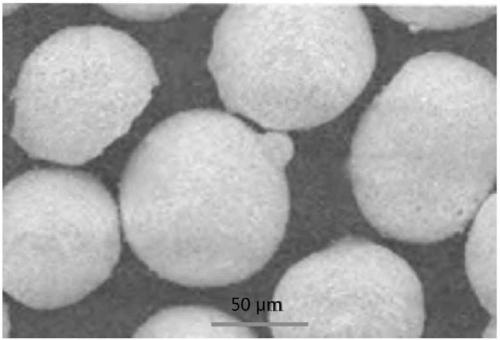

[0068] The zirconia-doped rare earth tantalate ceramic powder (Sc) prepared in Example 1 0.8 Ta 0.8 Zr 0.4 o 4 ) SEM spectrum such as figure 2 shown, from figure 2 It can be seen that the particle size range of the powder is 10-70 μm, and the shape is spherical. And the zirconia / titanium oxide / cerium oxide doped rare earth tantalum / niobate RETa / NbO that embodiment 2-12 obtains 4 The particle size range of the ceramic powder is 10-70 μm, and they all have a spherical shape.

[0069] Enumerate comparative example 3 groups and the ceramic powder that embodiment 1-12 obtains compares:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com