Tantalum or niobium or tantalum and niobium alloy additive manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The additive manufacturing method of dense tantalum of the present invention comprises the following steps:

[0037] (1) Prepare tantalum powder for 3D printing, the specific steps are as follows:

[0038] (a) Prepare the tantalum plate scraps, wash off the oil, soak in HF to remove the surface oxide film; then put it in a hydrogenation furnace and heat it up to 1000 ° C for 1 hour of vacuum treatment, then turn off the power and cool to 600 ° C, hydrogenate with hydrogen, and finally cool to room temperature Time to release.

[0039] (b) Use a 200-mesh sieve mill to sieve the hydrogenated tantalum material. The sieving and ball milling of the sieve mill are carried out at the same time. Every time the sieve mill rotates, the material is ball milled and sieved once. As long as the material particles reach The particle size corresponding to the 200-mesh sieve hole, the coarse particles whose particle size does not meet the requirements, will be returned to the ball mill...

Embodiment 2

[0045] The manufacturing method of this embodiment is exactly the same as that of Embodiment 1, the difference is that the blueprint of the design drawing is different, and it is printed according to the graphic converted from the bone scan intercepted by the doctor.

[0046] The product prepared in this embodiment is an internal grid tantalum bone, such as figure 2 As shown, the overall size is 157.2*29.51*20.7mm, and the bulk density is 2.64g / cm 3 , the porosity is 84.1%.

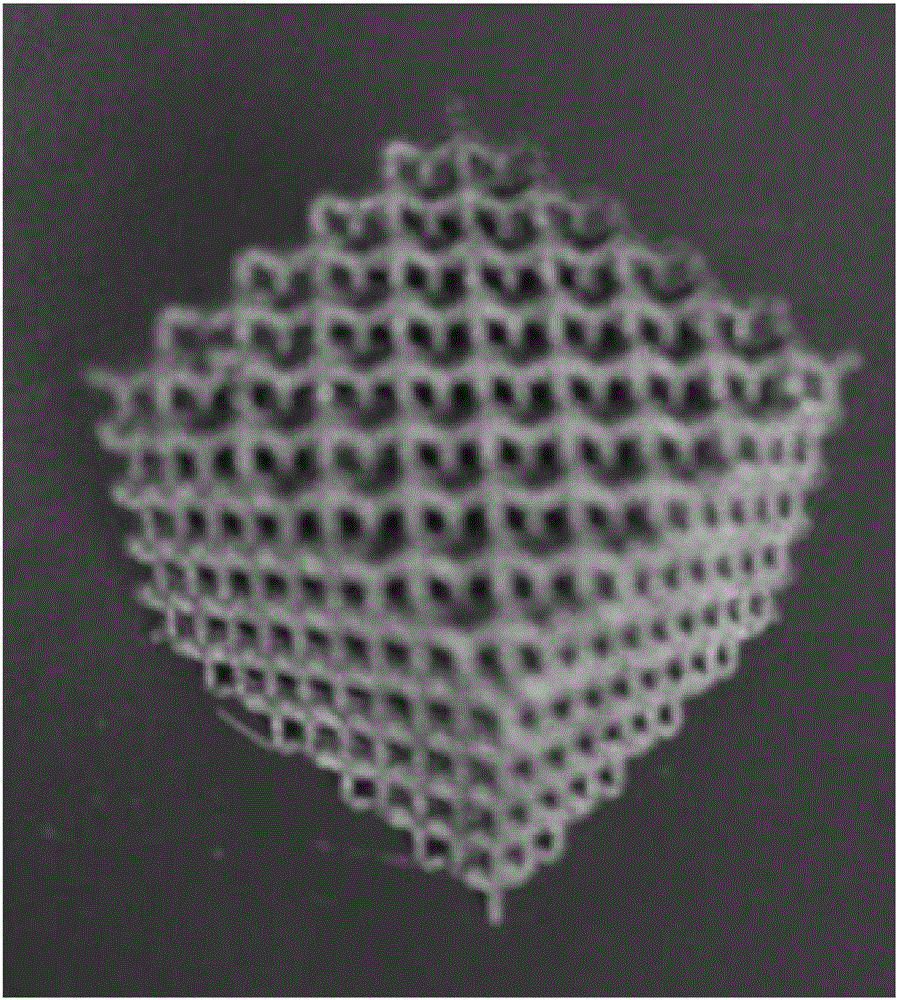

Embodiment 3

[0048] The present embodiment is the manufacturing method of grid niobium, comprises the following steps:

[0049] (1) Preparation of niobium powder for 3D printing, the specific steps are as follows:

[0050] (a) The niobium hydride obtained by the carbon reduction method is sieved and ground with a 200-mesh sieve mill, and the sieving and ball milling of the sieve mill are carried out simultaneously. Every time the sieve mill cylinder rotates around, the material is ball milled once and sieved once. As long as the particles reach the particle size corresponding to the 200-mesh sieve hole, if the particle size does not meet the required coarse particles, they will be returned to the ball mill again; the niobium hydride powder sieved by the 200-mesh sieve mill is placed in a 325-mesh vibrating sieve to obtain the particle size Niobium hydride powder larger than 325 mesh but smaller than 200 mesh. The peak particle size distribution of this kind of niobium hydride powder is ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com