Moisture-sensitive sensor based on potassium tantalite sensitive membrane and preparation method thereof

A humidity sensor, potassium tantalate technology, applied in the direction of material impedance, etc., to achieve the effects of low cost, good detection performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

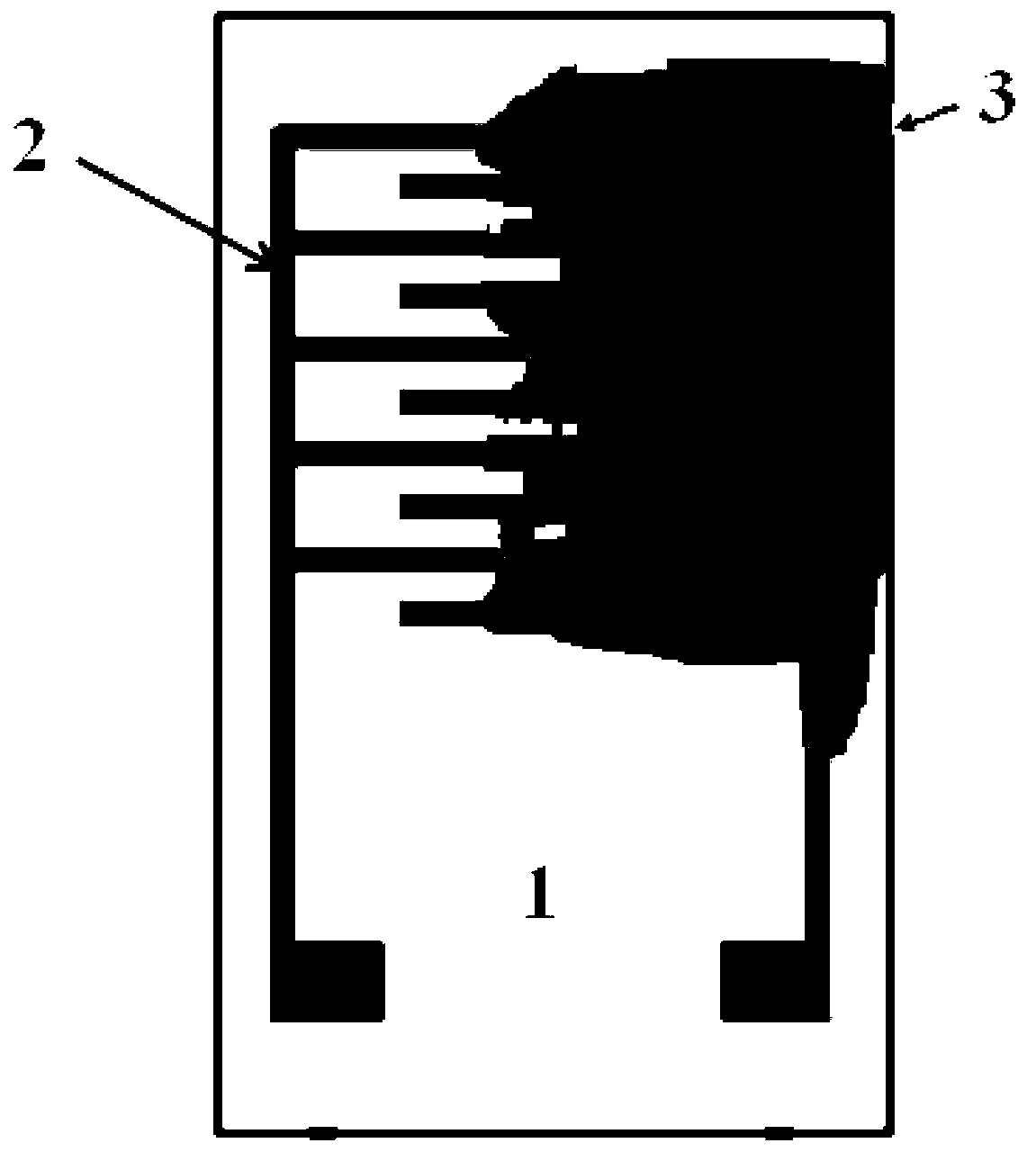

[0033] First, wipe the ceramic substrate with acetone and ethanol cotton balls until it is clean, then place the substrate in acetone, ethanol and deionized water in sequence, ultrasonically clean it for 5 minutes, and finally dry it at 100°C for later use;

[0034] Au metal interdigitated electrodes were prepared by screen printing technology. According to the mass ratio of ink (Jiahua JX07500487): Au powder: diluent (ethanol: ethyl acetate = 1.5:1), the mass ratio was 1:1.5:3, and stirred Prepare a paste; then inject the paste on the screen plate with the interdigitated electrode pattern, scrape the paste with an inclination angle of 30 degrees and a pressure of 5 N, print the electrode and dry it, and then use ultraviolet light After curing for 400s, metal interdigitated electrodes were prepared.

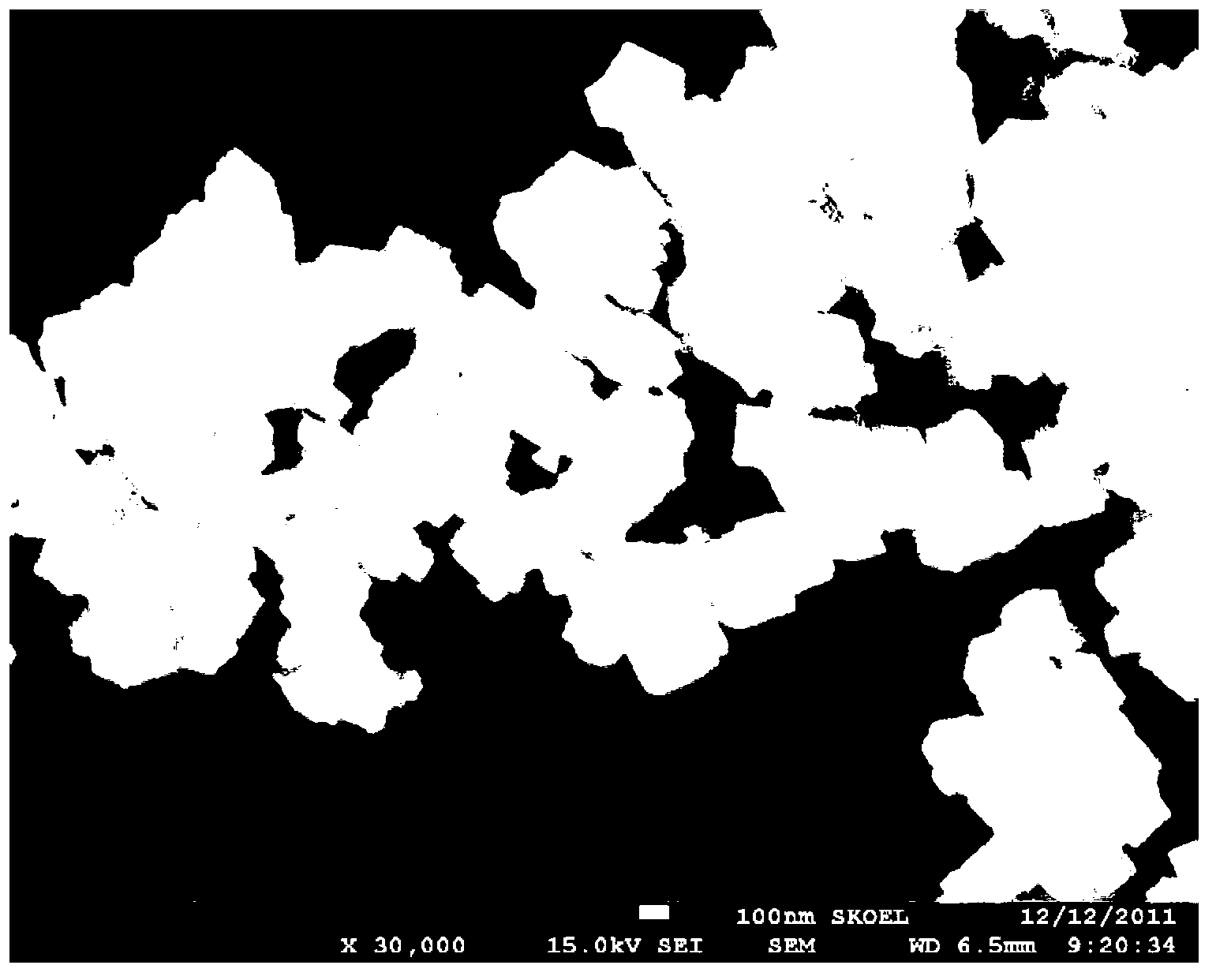

[0035] Preparation of potassium tantalate by hydrothermal method: Dissolve 4 g of potassium hydroxide in 10 mL of water at room temperature, stir the solution until it becomes cl...

Embodiment 2

[0039] First, wipe the substrate with acetone and ethanol cotton balls until it is clean, then place the substrate in acetone, ethanol and deionized water in sequence, ultrasonically clean it for 5 minutes, and finally dry it at 100°C for later use;

[0040] The preparation process of the Au metal interdigitated electrode is the same as that in Example 1.

[0041] Potassium tantalate was prepared by hydrothermal method: the experimental process was the same as in Example 1.

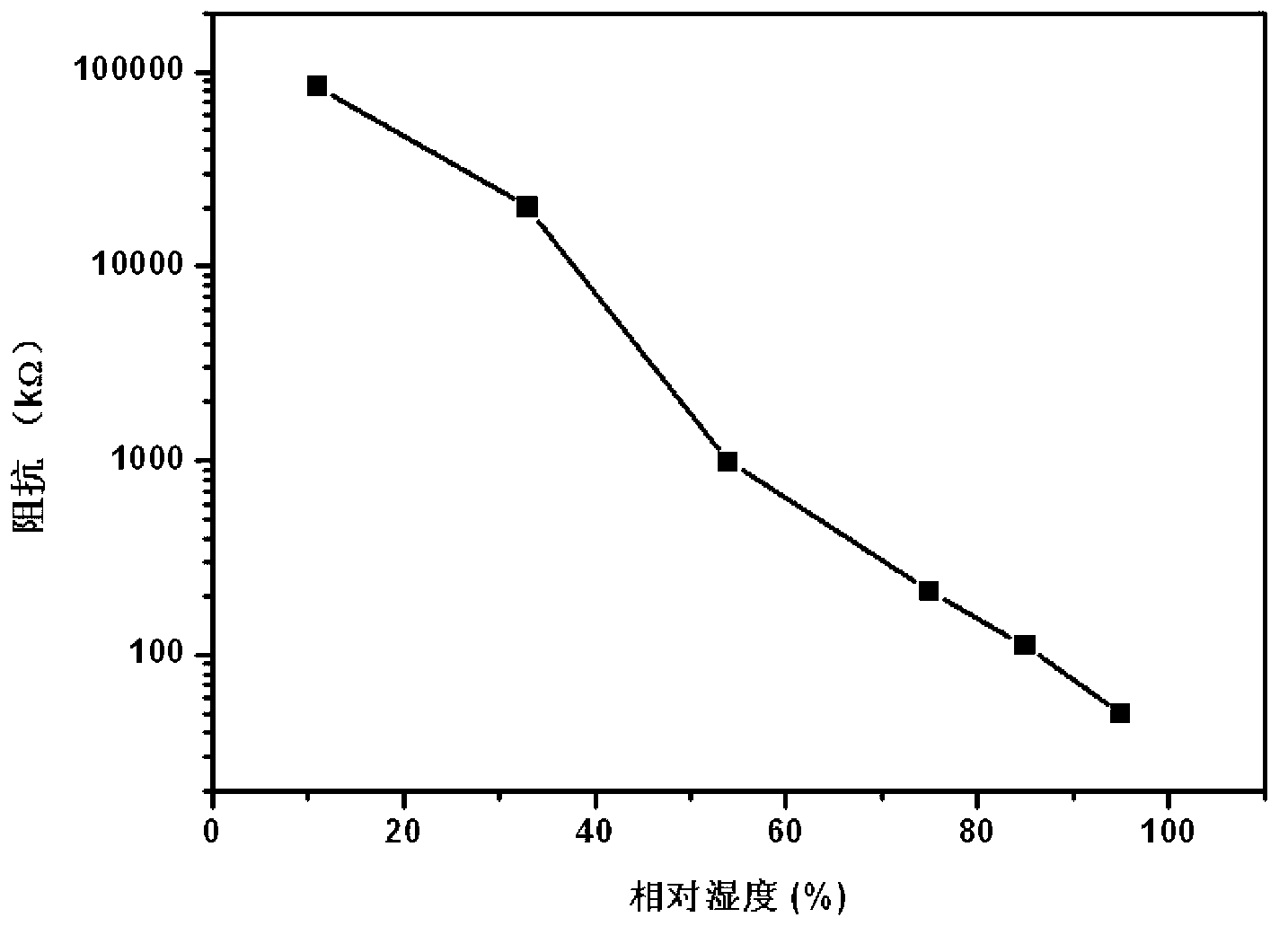

[0042] Put the dried potassium tantalate into a mortar and grind for 30 minutes; then drop deionized water into the mortar, and continue grinding for 30 minutes, so that the deionized water and materials are fully mixed to form a viscous slurry. . Dip a small amount of the sensitive film slurry with a spatula, coat it on the substrate, the number of coatings is 2 times, and then dry it at 60°C to obtain an element with a sensitive film thickness of 3 μm. Place the element prepared above in a humidity so...

Embodiment 3

[0045] First, wipe the substrate with acetone and ethanol cotton balls until it is clean, then place the substrate in acetone, ethanol and deionized water in sequence, ultrasonically clean it for 5 minutes, and finally dry it at 100°C for later use;

[0046] The preparation process of the Au metal interdigitated electrode is the same as that in Example 1.

[0047] Potassium tantalate was prepared by hydrothermal method: the experimental process was the same as in Example 1.

[0048] Put the dried potassium tantalate into a mortar and grind for 30 minutes; then drop deionized water into the mortar, and continue grinding for 30 minutes, so that the deionized water and materials are fully mixed to form a viscous slurry. . Dip a small amount of the sensitive film slurry with a spatula, coat it on the substrate for 3 times, and then dry it at 60°C to obtain an element with a sensitive film thickness of 4 μm. Place the element prepared above in a humidity source with a relative hu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com