Preparation method of high specific surface area tantalum powder and/or niobium powder

A technology with high specific surface area and tantalum powder, used in electrolytic capacitors, electrical components, circuits, etc., can solve the problems of low efficiency, complex process, and many reducing agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

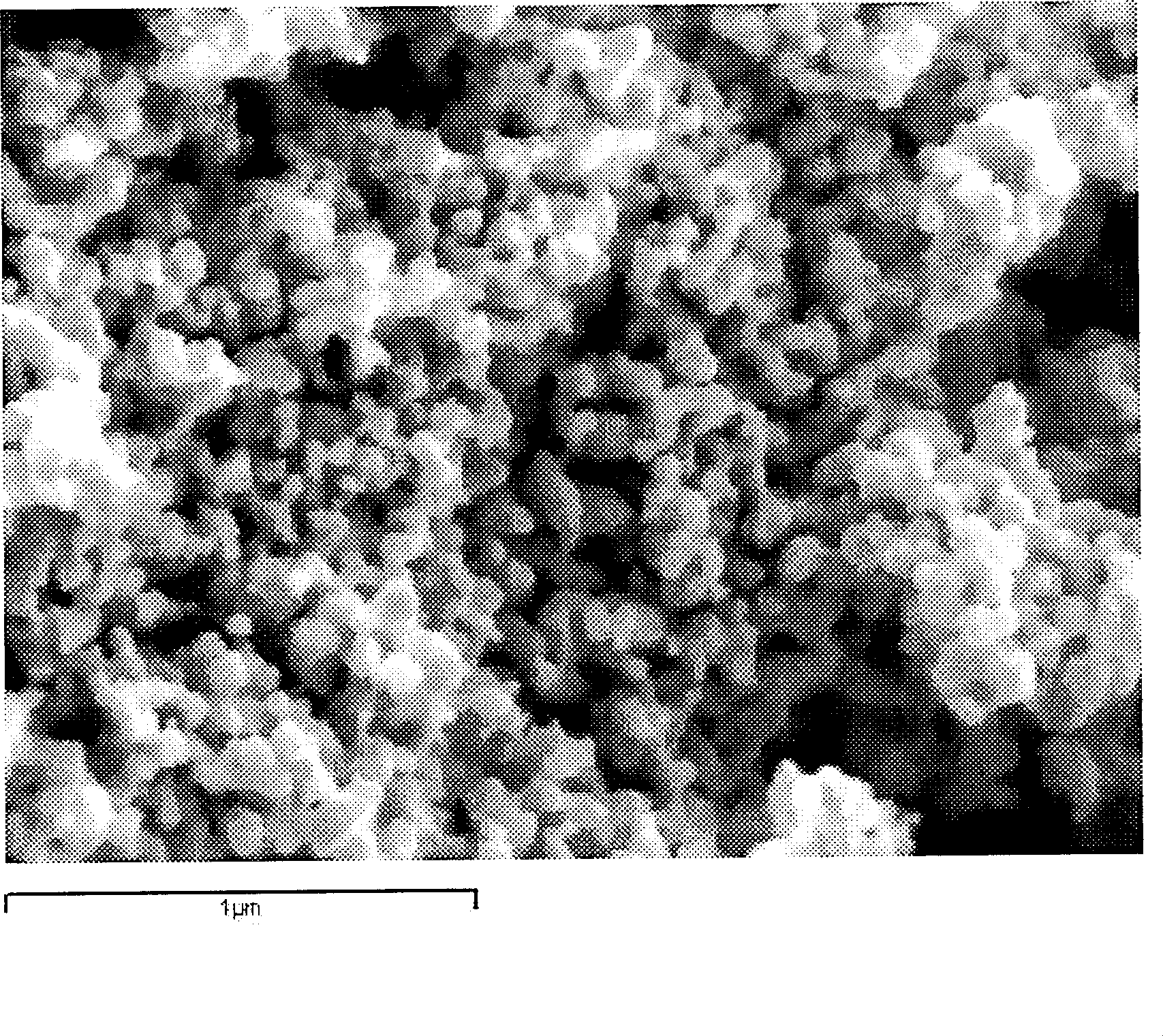

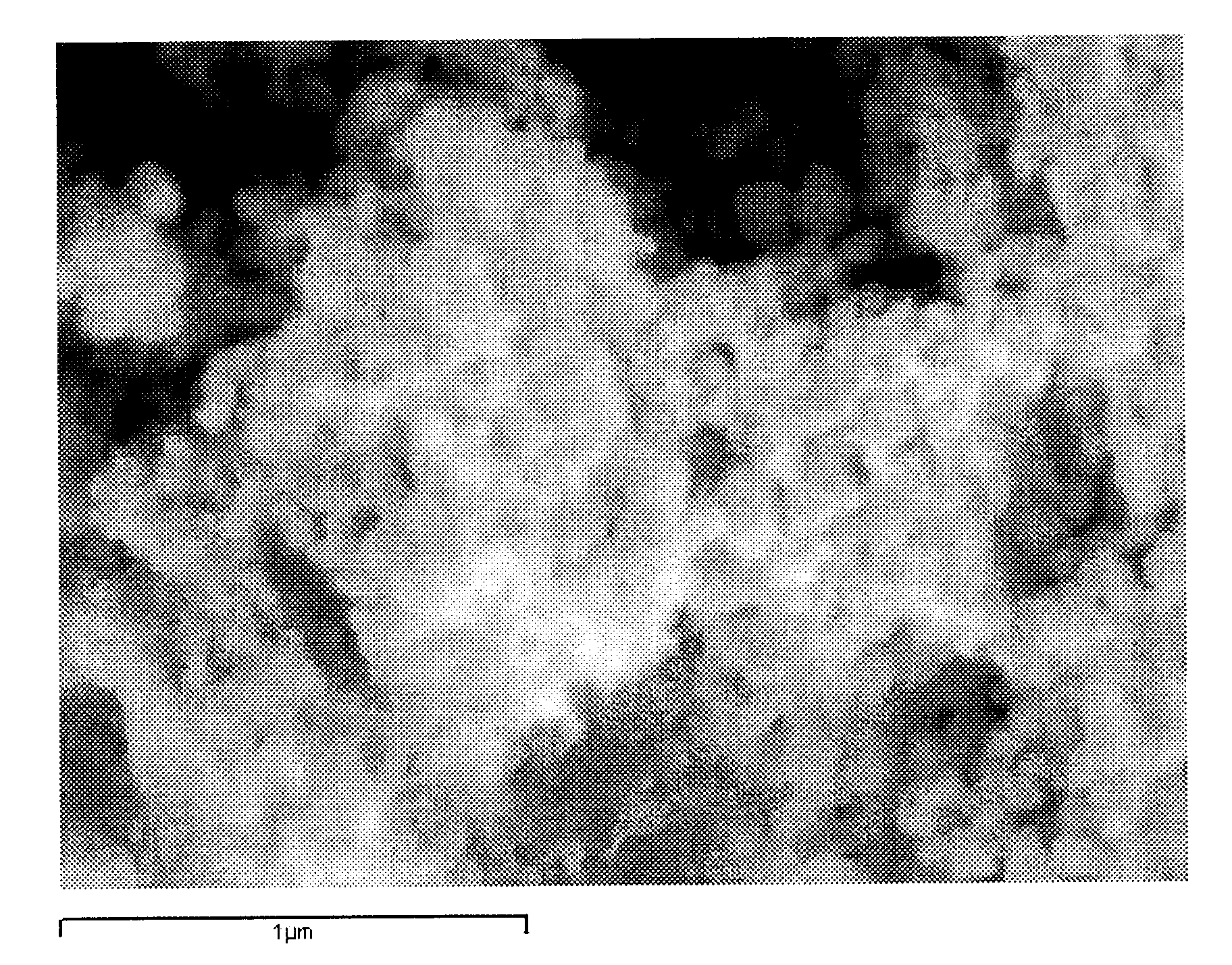

Image

Examples

Embodiment 1

[0036] The first step (reduction of tantalum oxide): use 4 kg of tantalum oxide, and 6 kg of MgCl 2 , 6 kg of KCl, 3 kg of NaCl, mix well, put it into a crucible, add 1 kg of metallic sodium, place it in a closed reactor, put in argon gas after vacuuming, heat it to 800 °C with an electric furnace, and keep it warm for 30 minutes. Reheat to 900°C and keep warm for 30 minutes.

[0037] The second step (separation of tantalum powder): after the reduction material in the first step is cooled, the reaction material is stripped from the crucible and broken, and the soluble salt and alkali metal are washed away with deionized water, washed with hydrochloric acid solution, and then Wash with deionized water until neutral to obtain tantalum powder, dry the tantalum powder, and sieve with a 100-mesh sieve to obtain 2953 grams of tantalum powder (original powder). The yield of tantalum powder is 90.15%. The bulk density (SBD), Fischer average particle size (FSSS), specific surface area...

Embodiment 2

[0071] The first step (reduction of tantalum oxide): use 10 kg of tantalum oxide and 15 kg of CaCl 2 , 22 kilograms of KCl, 10 kilograms of NaCl, put them into the reaction vessel, put argon and nitrogen into it after vacuuming, heat to 850°C with an electric furnace, when CaCl 2 , KCl, and NaCl are melted and stirred with a stirrer to disperse the tantalum oxide in the melt, cool the reactor, and inject 5250 grams of liquid metal sodium at a speed of 640 g / min to reduce the tantalum oxide to tantalum powder, and then Heat to 900°C and keep it warm for 60 minutes to make the reduction reaction fully proceed.

[0072] The second step (separation of tantalum powder): Then, after the material obtained in the first step is cooled, the reaction material is stripped from the reactor, broken, washed with deionized water to remove soluble salts and alkali metals, and then washed with hydrochloric acid. Wash with deionized water until neutral to obtain tantalum powder, dry the tantalu...

Embodiment 3

[0106] The first step (reduction of tantalum oxide): use 10 kg of tantalum oxide and 15 kg of CaCl 2 , 22 kilograms of KCl, 10 kilograms of NaCl, put into the reaction vessel, after vacuuming, argon and nitrogen are introduced, heated to 1050 °C with an electric furnace, stirred with a stirrer, so that tantalum oxide is dispersed in the melt, and the reactor Cool and inject 5510 grams of liquid metal sodium at a rate of 1020 g / min to reduce the tantalum oxide to tantalum powder, and keep the temperature at 1050° C. for 20 minutes to fully carry out the reduction reaction.

[0107] The second step (separation of tantalum powder): Then, after the material obtained in the first step is cooled, the reaction material is stripped from the reactor, broken, washed with deionized water to remove soluble salts and alkali metals, and then washed with hydrochloric acid. Wash with deionized water to neutral to obtain tantalum powder, dry this tantalum powder, sieve with 80 mesh sieves, obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com