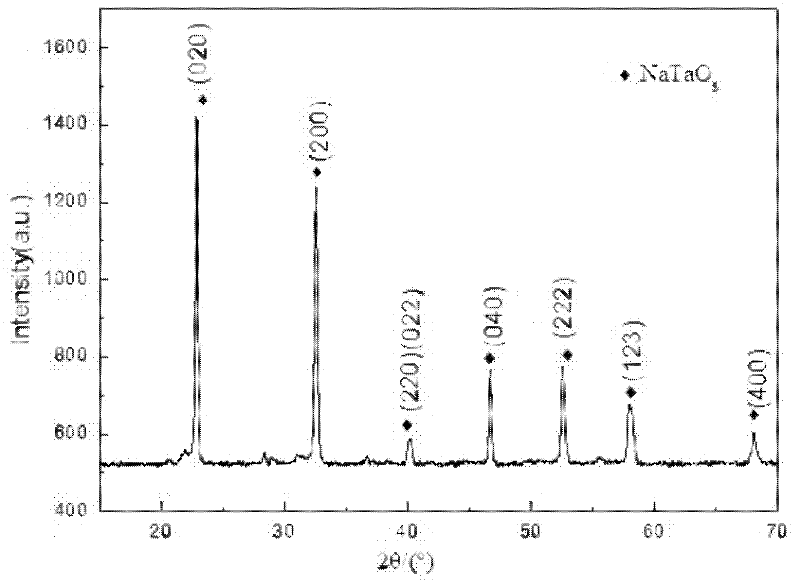

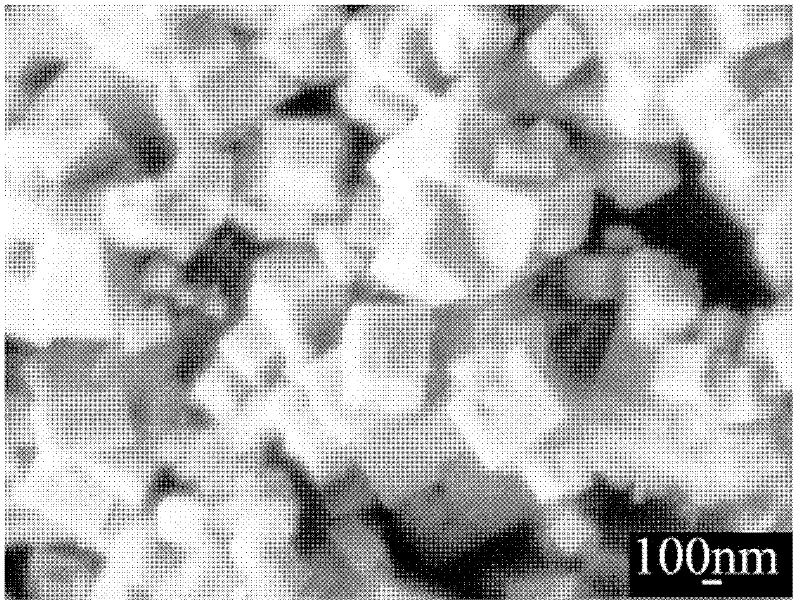

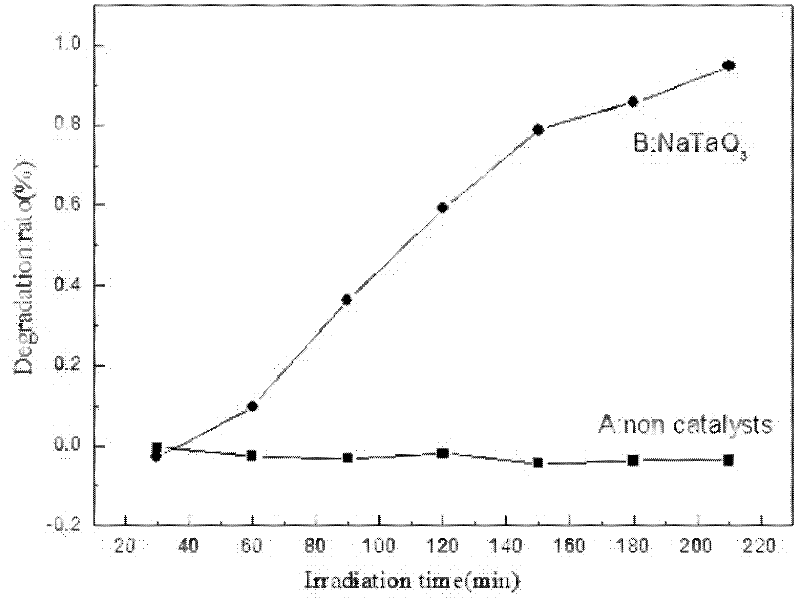

Method for preparing high catalytic activity sodium tantalate photo-catalyst by hydro-thermal method

A high catalytic activity, photocatalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of long reaction cycle, large powder particle size, Complicated preparation process and other issues to achieve good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Take Ta 2 o 5 (tantalum oxide), NaOH, add water to prepare a mixed solution, in which Ta 2 o 5 The concentration is 0.1mol / L, and the NaOH concentration is 1.0mol / L;

[0025] Step 2: Ultrasonic dispersion to completely dissolve NaOH, Ta 2 o 5 Dispersed into the solution to form a precursor;

[0026] Step 3: Put the precursor solution obtained in step 2 into the polytetrafluoroethylene lining with a filling rate of 80%, put the lining into the reaction kettle, seal the reaction kettle, and put it into a DHG type electric heating constant temperature blast drying oven , set the reaction temperature to 140°C, and stop the reaction after 12 hours of reaction time;

[0027] Step 4: After the reaction temperature drops to room temperature, take out the reaction kettle, pour out the supernatant in the lining, collect the precipitate, wash the precipitate with deionized water until it is neutral, and then wash it with absolute ethanol. Dry at 60°C to obtain sodiu...

Embodiment 2

[0031] Step 1: Take Ta 2 o 5 , NaOH, add water to prepare a mixed solution, in which Ta 2 o 5 The concentration is 0.1mol / L, and the NaOH concentration is 0.4mol / L;

[0032] Step 2: Ultrasonic dispersion to completely dissolve NaOH, Ta 2 o 5 Dispersed into the solution to form a precursor;

[0033] Step 3: Put the precursor solution obtained in step 2 into the polytetrafluoroethylene lining with a filling rate of 80%, put the lining into the reaction kettle, seal the reaction kettle, and put it into a DHG type electric heating constant temperature blast drying oven , set the reaction temperature to 120°C, and stop the reaction after 12 hours of reaction time;

[0034] Step 4: After the reaction temperature drops to room temperature, take out the reaction kettle, pour out the supernatant in the lining, collect the precipitate, wash the precipitate with deionized water until it is neutral, and then wash it with absolute ethanol. Dry at 60°C to obtain sodium tantalate powd...

Embodiment 3

[0036] Step 1: Take Ta 2 o 5 , NaOH, add water to prepare a mixed solution, in which Ta 2 o 5 The concentration is 0.1mol / L, and the NaOH concentration is 2.0mol / L;

[0037] Step 2: Ultrasonic dispersion to completely dissolve NaOH, Ta 2 o 5 Dispersed into the solution to form a precursor;

[0038] Step 3: Put the precursor solution obtained in step 2 into the polytetrafluoroethylene lining with a filling rate of 80%, put the lining into the reaction kettle, seal the reaction kettle, and put it into a DHG type electric heating constant temperature blast drying oven , set the reaction temperature to 180°C, and stop the reaction after 12 hours of reaction time;

[0039] Step 4: After the reaction temperature drops to room temperature, take out the reaction kettle, pour out the supernatant in the lining, collect the precipitate, wash the precipitate with deionized water until it is neutral, and then wash it with absolute ethanol. Dry at 60°C to obtain sodium tantalate powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com