Method for extracting tantalum and niobium through low alkali decomposition of tantalum-niobium ore

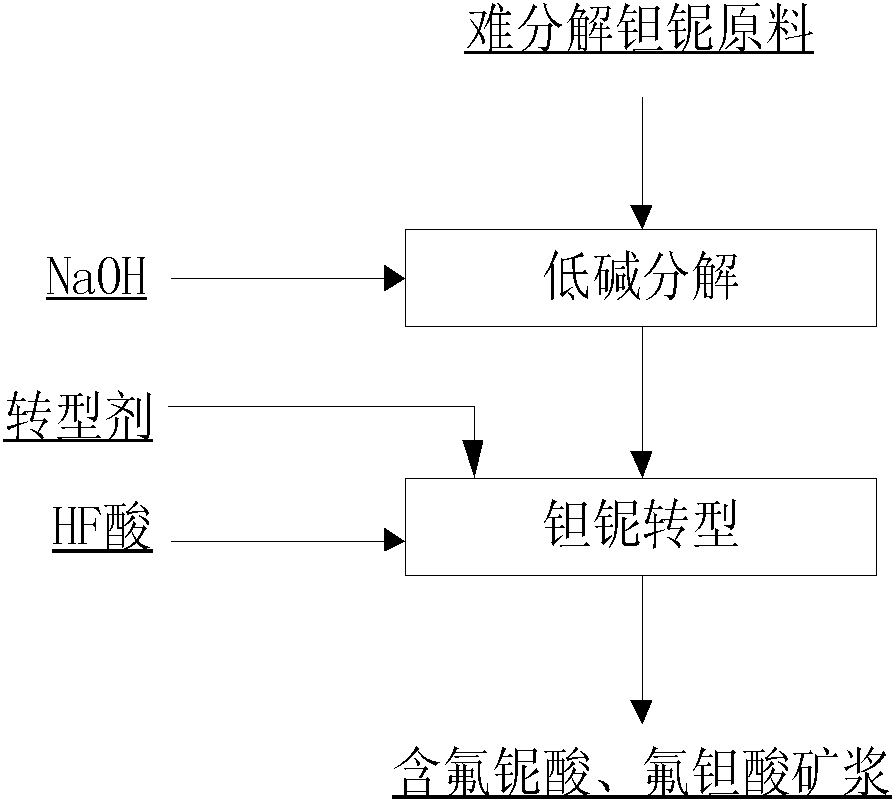

A technology of tantalum-niobium ore and niobic acid, which is applied in the field of tantalum-niobium ore decomposition, can solve the problems of high decomposition temperature, large alkali consumption, fluorine pollution, etc., and achieves the effects of high decomposition rate, reduced alkali consumption and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] After mixing sodium hydroxide and tantalum-niobium ore evenly, put them into a muffle furnace, the mass ratio of alkali ore in the mixture is 1:1, the initial mineral particle size of tantalum-niobium ore is 58-75 μm, decompose at 650°C for 30 minutes, and react After finishing, obtain the decomposition product containing sodium metatantalate and sodium metaniobate and a small amount of sodium tantalate and sodium niobate, after the decomposition product cools down to normal temperature, add 5ml 0.6mol / L fluosilicic acid and use initial concentration as 4.00mol / L hydrofluoric acid was leached for 2 hours at 60°C under the condition that the liquid-solid ratio (m:v) was 10:1, and the ore pulp was obtained after leaching.

[0020] According to ICP-AES analysis, the decomposition rates of tantalum and niobium in tantalum-niobium ore are 99.2% and 99.5%, respectively.

Embodiment 2

[0022] After mixing sodium hydroxide and tantalum-niobium ore evenly, put them into a muffle furnace. The mass ratio of alkali ore in the mixture is 12:1. The initial mineral particle size of tantalum-niobium ore is 75-106 μm. Decompose at 600°C for 50 minutes, and react After finishing, obtain the decomposition product containing sodium metatantalate and sodium metaniobate and a small amount of sodium tantalate and sodium niobate, after the decomposition product is cooled to normal temperature, add 0.5g quartz and use initial concentration to be 5.06mol / L hydrogen Under the conditions of 70°C and liquid-solid ratio (m:v) of 8:1, the hydrofluoric acid was transformed and leached for 3 hours, and the ore pulp was obtained after leaching.

[0023] According to ICP-AES analysis, the decomposition rates of tantalum and niobium in tantalum-niobium ore are 99.1% and 99.3%, respectively.

Embodiment 3

[0025] After mixing sodium hydroxide and tantalum-niobium ore evenly, put them into a muffle furnace, the mass ratio of alkali ore in the mixture is 1.5:1, the initial mineral particle size of tantalum-niobium ore is 58-75 μm, decompose at 550°C for 60 minutes, and react After finishing, obtain the decomposition product containing sodium metatantalate and sodium metaniobate and a small amount of sodium tantalate and sodium niobate, after the decomposition product is cooled to normal temperature, add 0.8g silica gel and use initial concentration to be 5.39mol / L hydrogen Under the conditions of 80°C and liquid-solid ratio (m:v) of 7:1, the hydrofluoric acid was transformed and leached for 2 hours, and the ore pulp was obtained after leaching.

[0026] According to ICP-AES analysis, the leaching rates of tantalum and niobium in tantalum-niobium ore are 99.1% and 99.5%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com