Transparent conductive film as well as preparation method and application thereof

A technology of transparent conductive film and conductive film, which is applied in the direction of oxide conductors, non-metallic conductors, ion implantation plating, etc., can solve the problems of poor conductivity and light transmittance, and can not achieve the effect, so as to achieve the improvement of conductivity and preparation method The effect of simple and easy operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

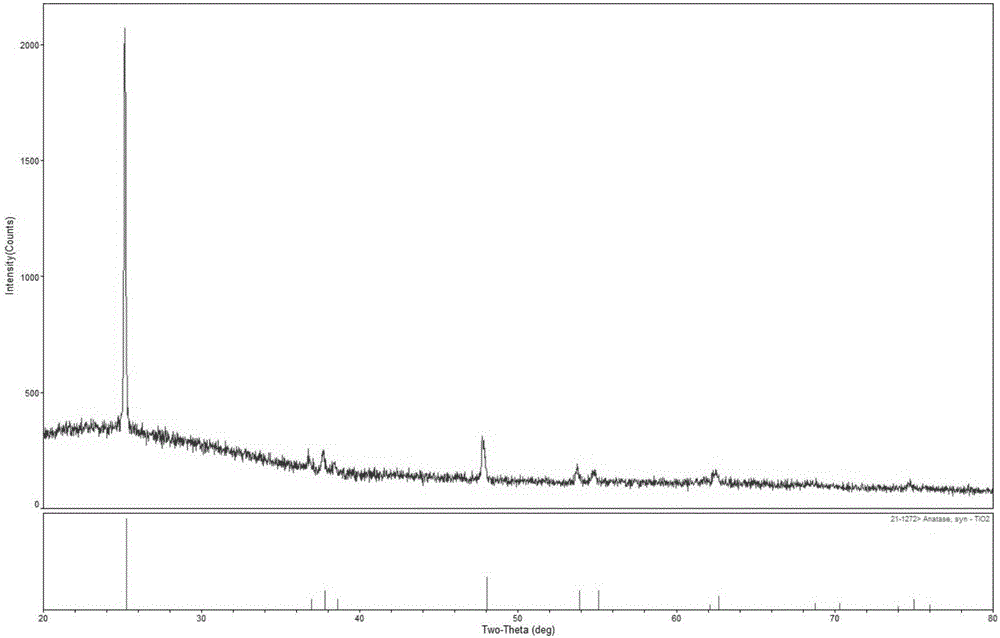

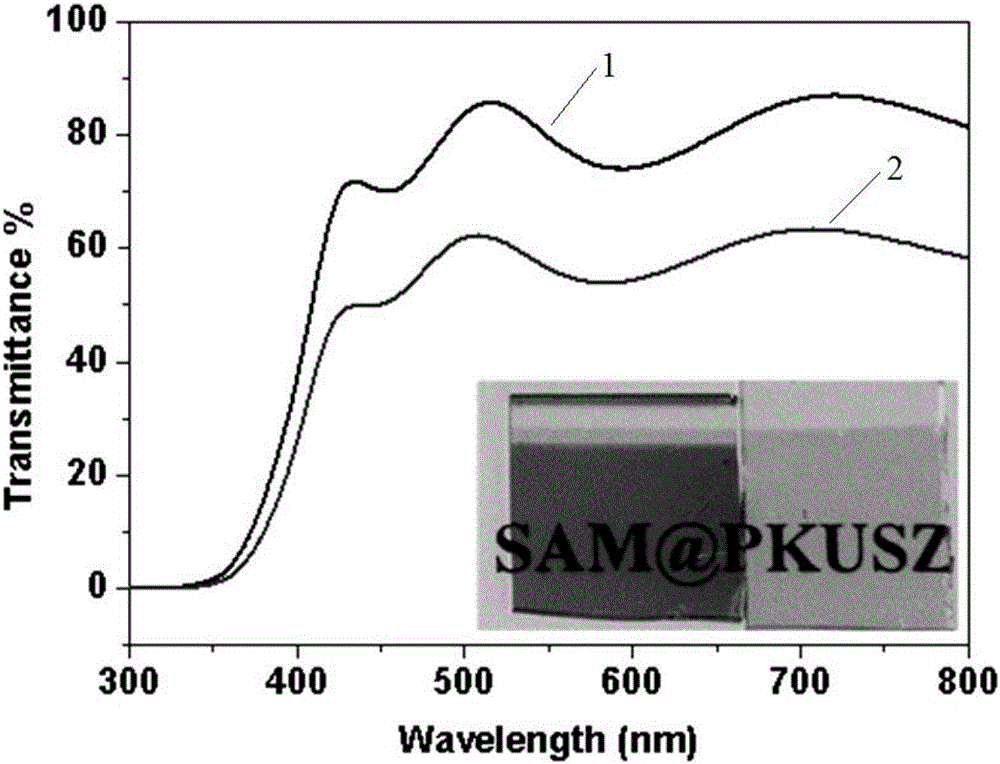

[0039] For the transparent conductive film of this example, a niobium-doped titanium dioxide film was prepared by magnetron sputtering, and then treated with ruthenium chloride to obtain a ruthenium-doped and niobium-doped titanium dioxide film. details as follows:

[0040] (1) Titanium dioxide powder and niobium pentoxide powder are used as the main raw materials, the purity is 4N-5N, and the molar ratio of Ti:Nb is 9:1. After mixing, it is ground to make it evenly mixed. Then put it into a high-temperature silicon-molybdenum furnace and pre-fire at 820°C for 3 hours; after completion, add 5mL of polyvinyl alcohol as a polymerizer, press it into a circular target with a thickness of 4.5mm and a diameter of 5cm with a powder tablet press, and then put it into a high-temperature silicon-molybdenum target. Sinter in a molybdenum furnace at 5°C / min to 1350°C for 5h. After cooling, fix a 0.5mm thick copper backing to prepare a niobium-doped titanium dioxide target. (2) The obtain...

Embodiment 2

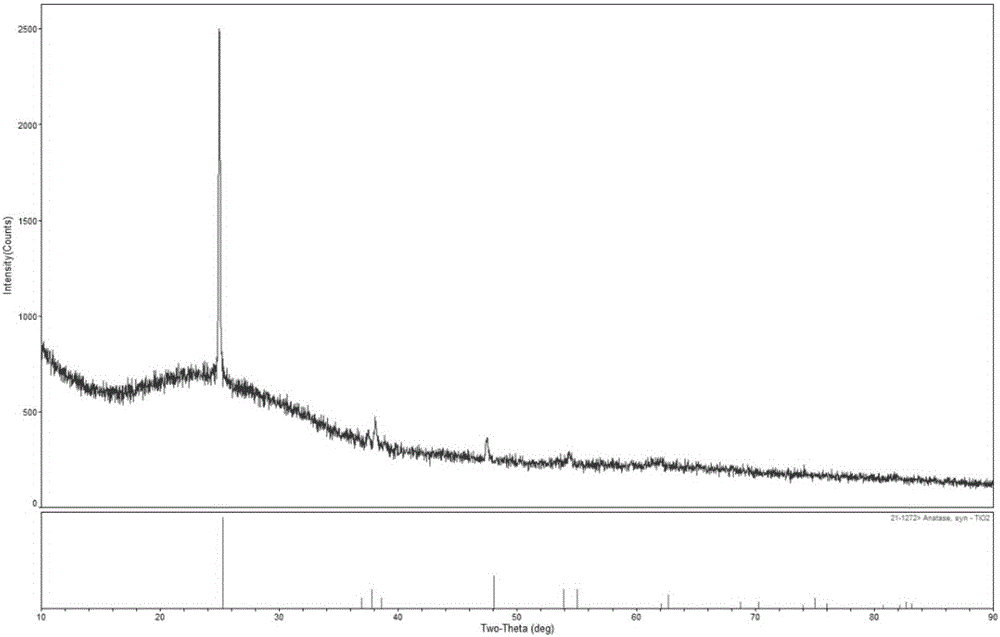

[0044] The transparent conductive film of this example is prepared by magnetron sputtering method to prepare tantalum-doped titanium dioxide film, and then treated with ruthenium chloride to obtain ruthenium-doped and tantalum-doped titanium dioxide film. details as follows:

[0045] (1) The tantalum source in this example is tantalum pentoxide with a purity of 4N to 5N. The Ti:Ta molar ratio is 19:1, and the tantalum-doped titanium dioxide target is prepared by the same method as in Example 1. (2) Then magnetron sputtering is performed on the tantalum-doped titanium dioxide target to prepare a tantalum-doped titanium dioxide film. The magnetron sputtering conditions are as follows: the pressure of the sputtering chamber is 1.0Pa, the atmosphere of the sputtering chamber is argon, and the substrate is Soda lime silica glass, substrate temperature is 50°C, sputtering power is 0.3W / cm 2 , the deposition rate was 8nm / min, the sputtering time was 1h, and a tantalum-doped titanium...

Embodiment 3

[0049] For the transparent conductive film of this example, niobium and tantalum-doped titanium dioxide films were prepared by magnetron sputtering, and then treated with ruthenium chloride to obtain ruthenium-doped, niobium-doped and tantalum-doped titanium dioxide films. details as follows:

[0050] (1) The source of niobium in this example is niobium pentoxide, the source of tantalum is tantalum pentoxide, the purity is 4N-5N, and the molar ratio of Ti:Nb:Ta is 18:1:1. The same ingredients as in Example 1 are used. The preparation method of niobium and tantalum doped titania targets. (2) Then magnetron sputtering was performed on niobium and tantalum doped titanium dioxide targets to prepare tantalum doped titanium dioxide films. The bottom is soda-lime-silica glass, the substrate temperature is 200°C, the sputtering power is 0.3W / cm2, the deposition rate is 8nm / min, and the sputtering time is 1h, and a niobium and tantalum doped titanium dioxide film with a thickness of 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com